Gas valve online quick-speed leak detection method

A valve and fast technology, applied in the field of detection, can solve the problems of affecting continuous and stable gas supply, wasting energy, low sensitivity, etc., and achieve the effect of increasing implementation frequency, reducing labor costs, and high accuracy and sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] (1) Maintain a certain pressure difference on both sides of the valve

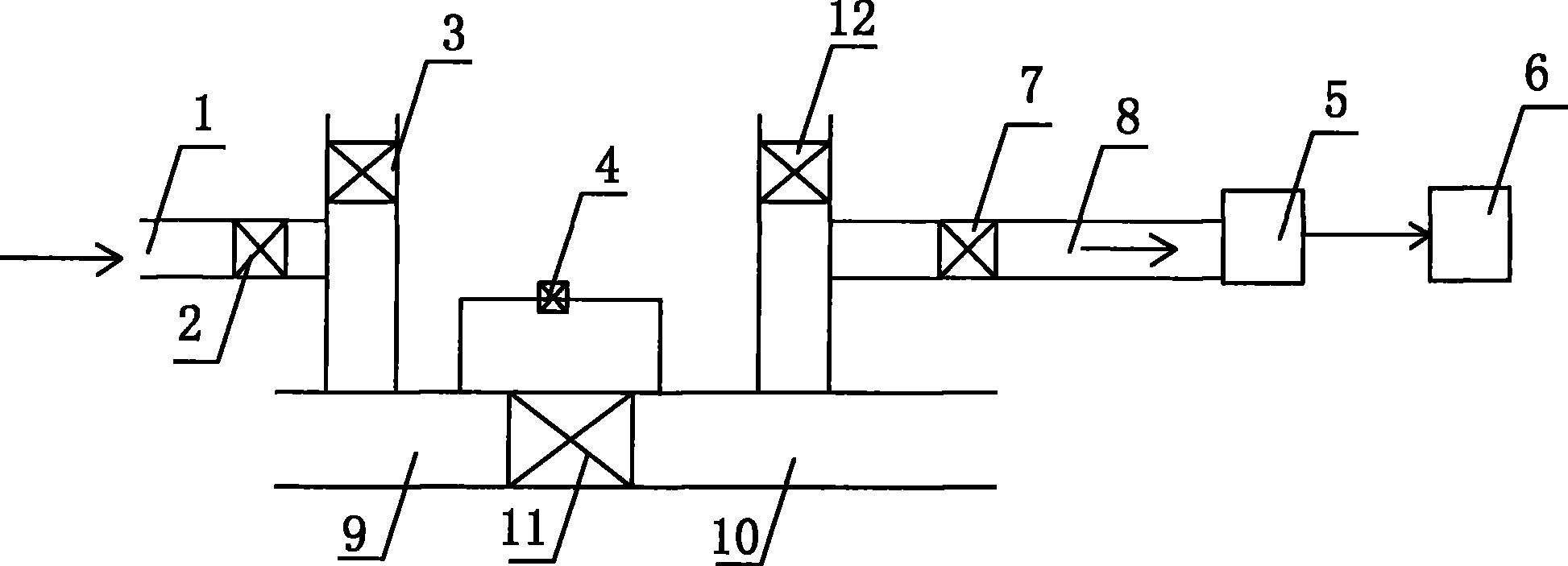

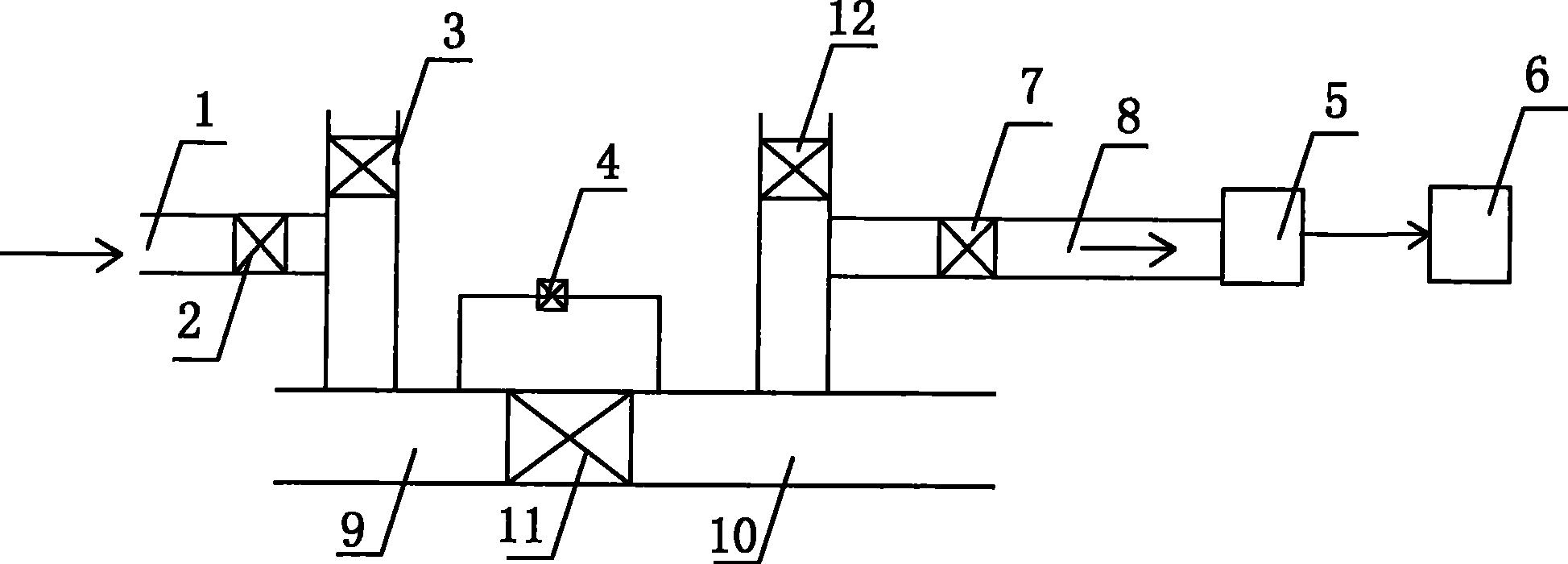

[0027] In the case of normal gas supply, close the valve and maintain a certain pressure difference on both sides of the valve, as shown in Figure 1, keep P1>P2, and select the difference between P1 and P2 as 0.02Mpa.

[0028] (2) adding tracer gas;

[0029] Add tracer gas at the P1 side of the higher pressure side, and the amount of tracer gas added is 20000-21000g.

[0030] The tracer substance must be inert, not easy to auto-oxidize, non-corrosive, safe, and not affect the gas quality. The tracer substance must also not exist in the gas, and is a gas at normal temperature and pressure, so as to meet the analysis requirements. Through the screening of a large number of substances, the applicant selected ether substances as the tracer gas. After the applicant's long-term and large amount of experiments, one by one gas was checked, and dimethyl ether was first selected as the tracer gas.

[0031...

Embodiment 2

[0038] The operation steps are the same as in Example 1, the difference between P1 and P2 on both sides of the valve is kept at 0.05Mpa, and a tracer gas is added to the P1 end on the side with higher pressure, and the amount of tracer gas added is 80g-100g. Other operations are the same as in Example 1, the tracer gas is collected and enriched, and analyzed by gas chromatography.

Embodiment 3

[0040] (1) Maintain a certain pressure difference on both sides of the valve

[0041] In the case of normal air supply, close the valve and maintain a certain pressure difference on both sides of the valve, as shown in Figure 1, keep P1>P2, and keep the difference between P1 and P2 at 0.03-0.04Mpa.

[0042] (2) adding tracer gas;

[0043] Add tracer gas at the P1 end of the side with higher pressure, and the amount of tracer gas added is 200g-300g.

[0044] The tracer substance must be inert, not easy to auto-oxidize, non-corrosive, safe, and not affect the gas quality. The tracer substance must also not exist in the gas, and is a gas at normal temperature and pressure, so as to meet the analysis requirements. Through the screening of a large number of substances, the applicant selected ether substances as the tracer gas. After the applicant's long-term and large amount of experiments, one by one gas was checked, and dimethyl ether was first selected as the tracer gas.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com