Optical point-checking device correcting instrument

A point-to-point and calibration technology, applied in the field of surveying and mapping instruments, can solve the problems of the point-pointing device being unable to be calibrated, having no versatility, and high labor intensity, achieving flexible and stable rotation and braking, high labor intensity, and reduced labor intensity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

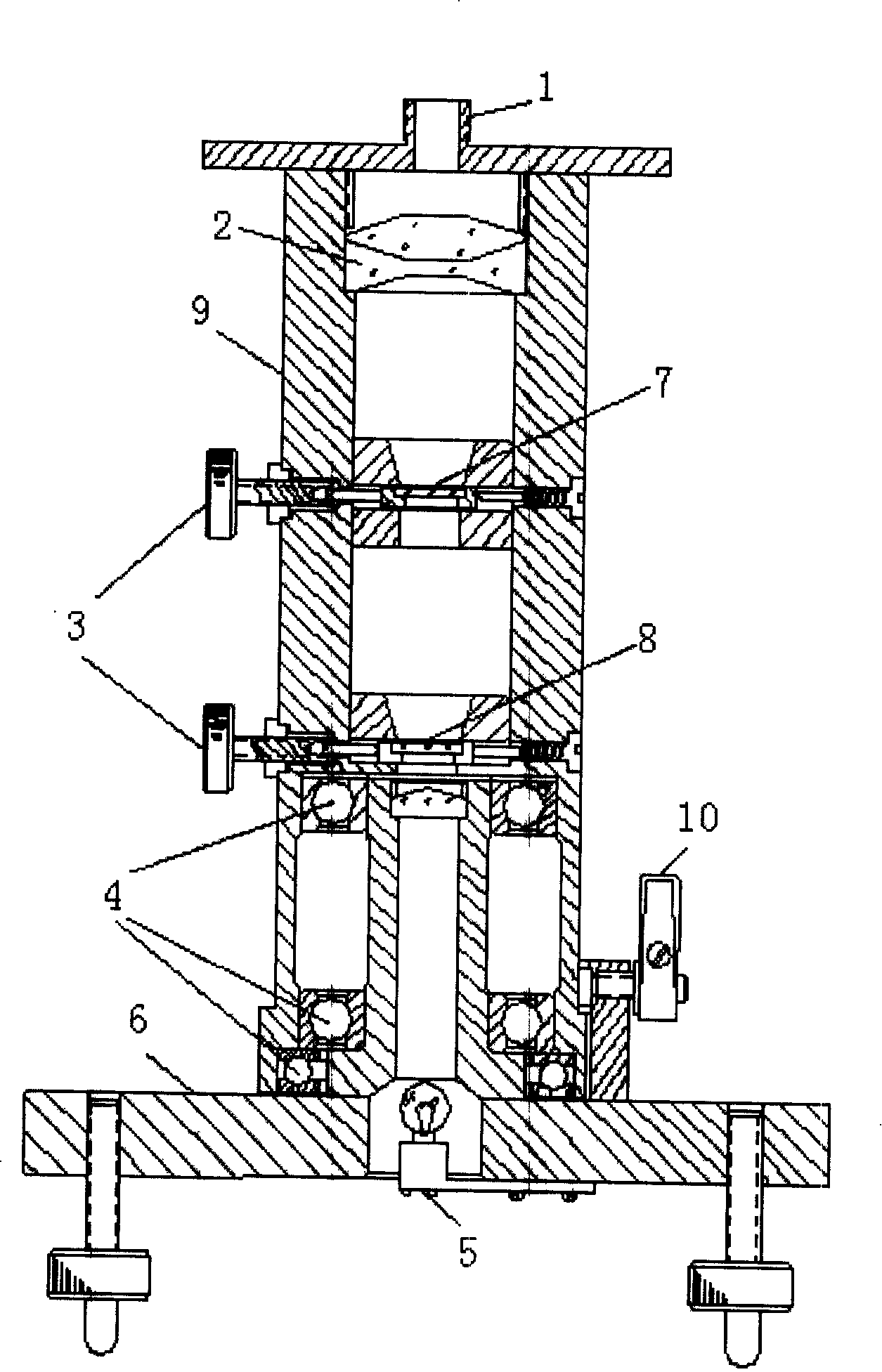

[0031] 1. Hold the theodolite, align the central screw hole at the bottom of the theodolite with the M16 screw on the upper part of the calibrator, turn the optical tube to tighten it, and roughly level the theodolite so that the optical axis of the optical plummet enters the optical tube of the calibrator. The operator sits in front of the calibration instrument. During the calibration process, the eyepiece of the optical plummet is facing the operator, and the 6v power supply is connected.

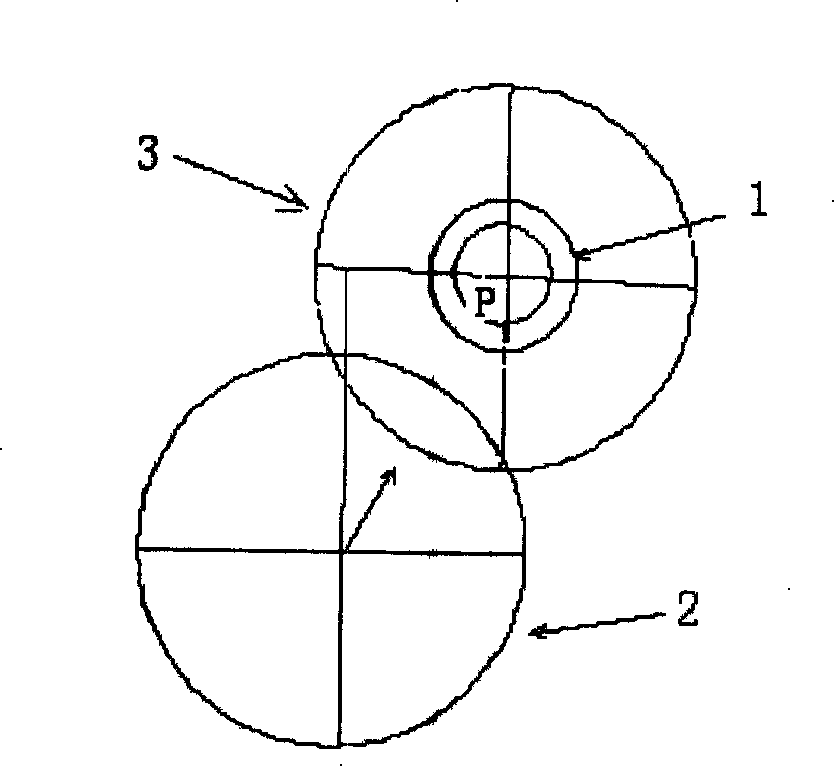

[0032] 2. Adjust the focal length of the optical plummet, see the reticle I clearly, and turn the two mutually perpendicular micro-movement spirals on the optical tube to make the intersection of the reticle I and the optical plummet separate. The reticle circle on the reticle conforms to figure 2 .

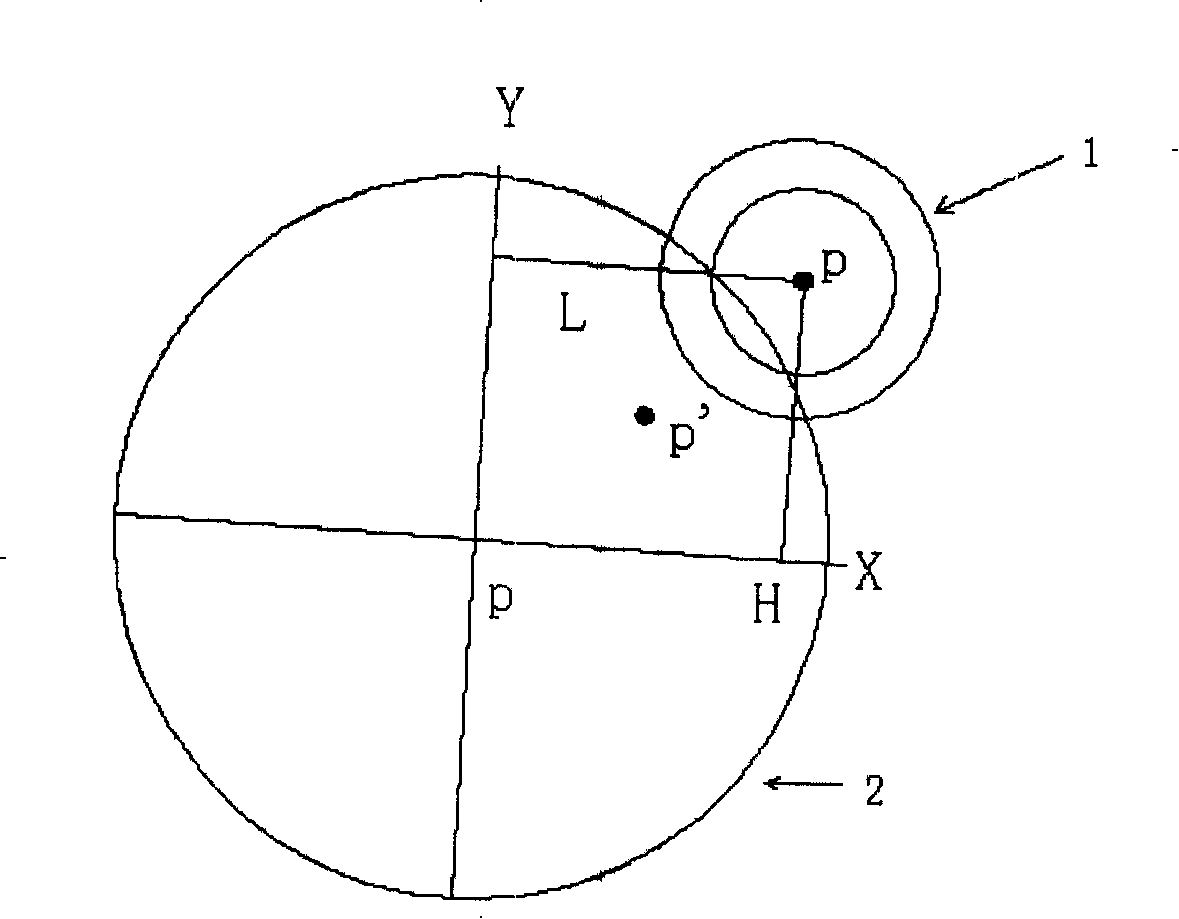

[0033] 3. Turn the light tube 180 degrees, lock the brake knob on the light tube, and observe the alignment between the reticle circle of the dot aligner and the axis of the reticle I. R...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com