Wire rope end connector fatigue test apparatus

A fatigue test and wire rope technology, applied in the direction of using repetitive force/pulse force to test the strength of materials, measuring devices, instruments, etc., can solve the problems of inability to adjust, long test time, low efficiency, etc., and achieve a wide range of applications and high efficiency. 、Convenient, fast and accurate data analysis and collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

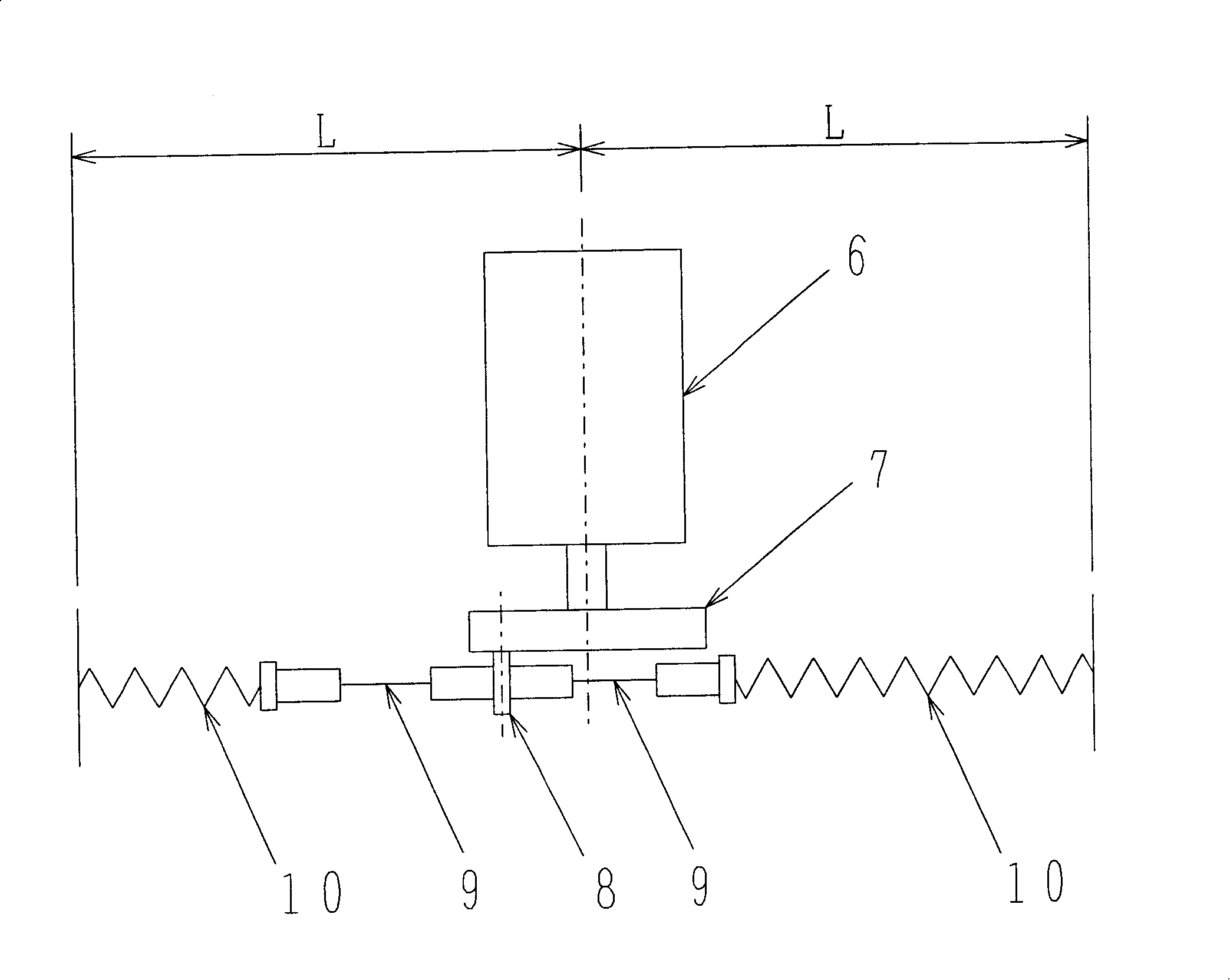

[0017] Such as figure 2 As shown in the schematic diagram, the fatigue testing machine according to the first embodiment of the present invention includes: a motor 6 used as a power mechanism, an eccentric wheel 7 used as a rotating mechanism, arranged on the eccentric wheel and connected to two rope ends respectively One end of the test piece 9 is fixedly connected to a connecting part 8, and two springs 10 are fixedly connected to the other end of the rope end joint test piece 9 through the connecting part. The connecting part 8 is fixed on the eccentric wheel 7 and deviates from the central axis of the eccentric wheel by a certain distance. Each rope end joint test piece 9 consists of two rope end joints and a wire rope between them. The other end of the spring 10 is connected with a fixed bracket. In addition, the connecting parts 8 for fixedly connecting the eccentric wheel 7 and two opposite rope end joints can be made of various forms such as bolts and nuts, bearings...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com