Smart card preparing technique

A preparation process and technology for smart cards, which are applied to record carriers, instruments, computer parts, etc. used in machines, can solve the problems of lowering the yield of smart cards and increasing production costs, and achieve easy quality control, lower production costs, and higher production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

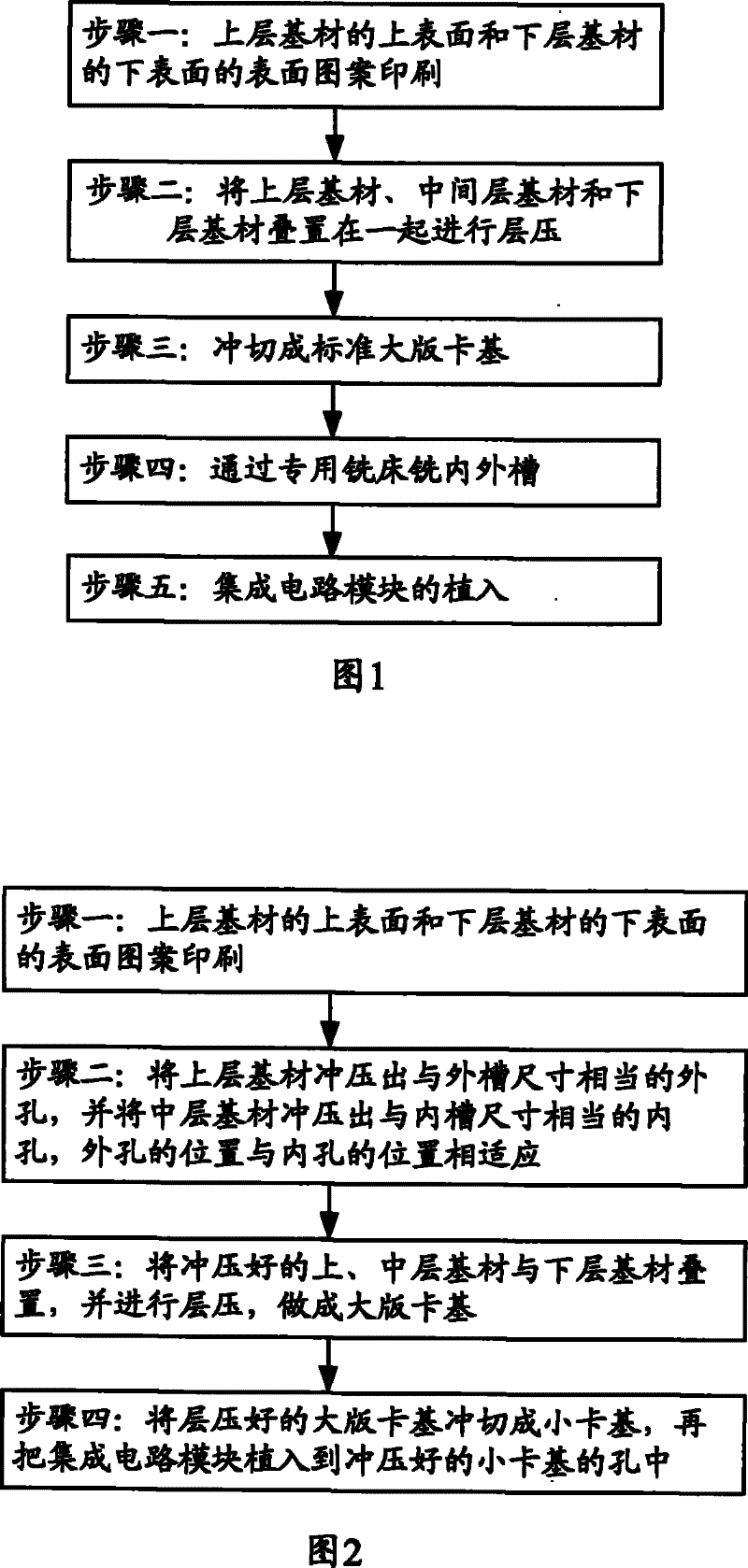

[0026] like figure 2 As shown, the present invention specifically includes:

[0027] Step 1: Firstly, print patterns on the upper surface of the upper substrate and the lower surface of the lower substrate, which is the same as the conventional process;

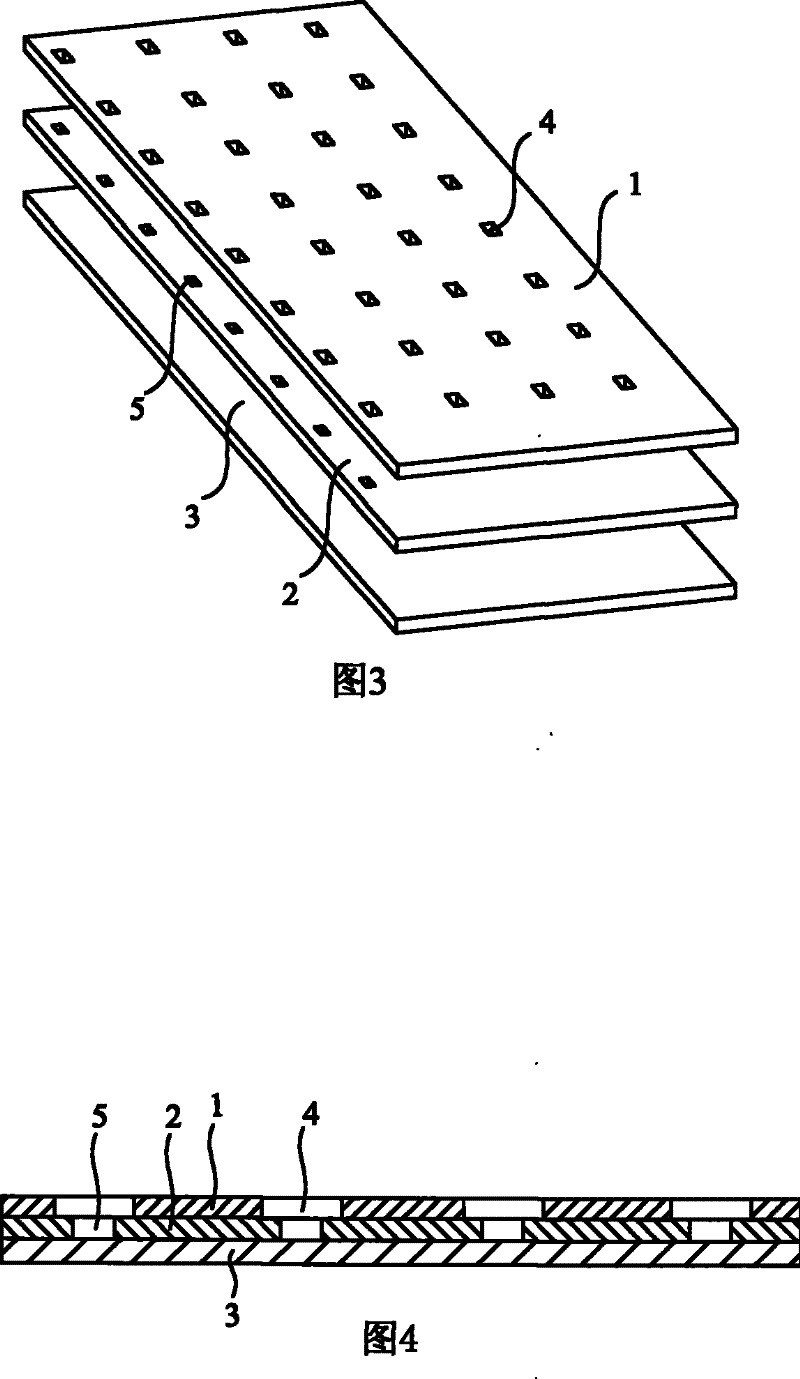

[0028] Step 2: As image 3 As shown, the upper base material 1 is punched out with an outer hole 4 corresponding to the size of the outer tank, and the middle base material 2 is punched out with an inner hole 5 corresponding to the size of the inner tank. The position of the outer hole 4 is the same as that of the inner hole 5. Adaptation, the purpose is to ensure that the center of the outer hole coincides with the center of the inner hole in the subsequent lamination process;

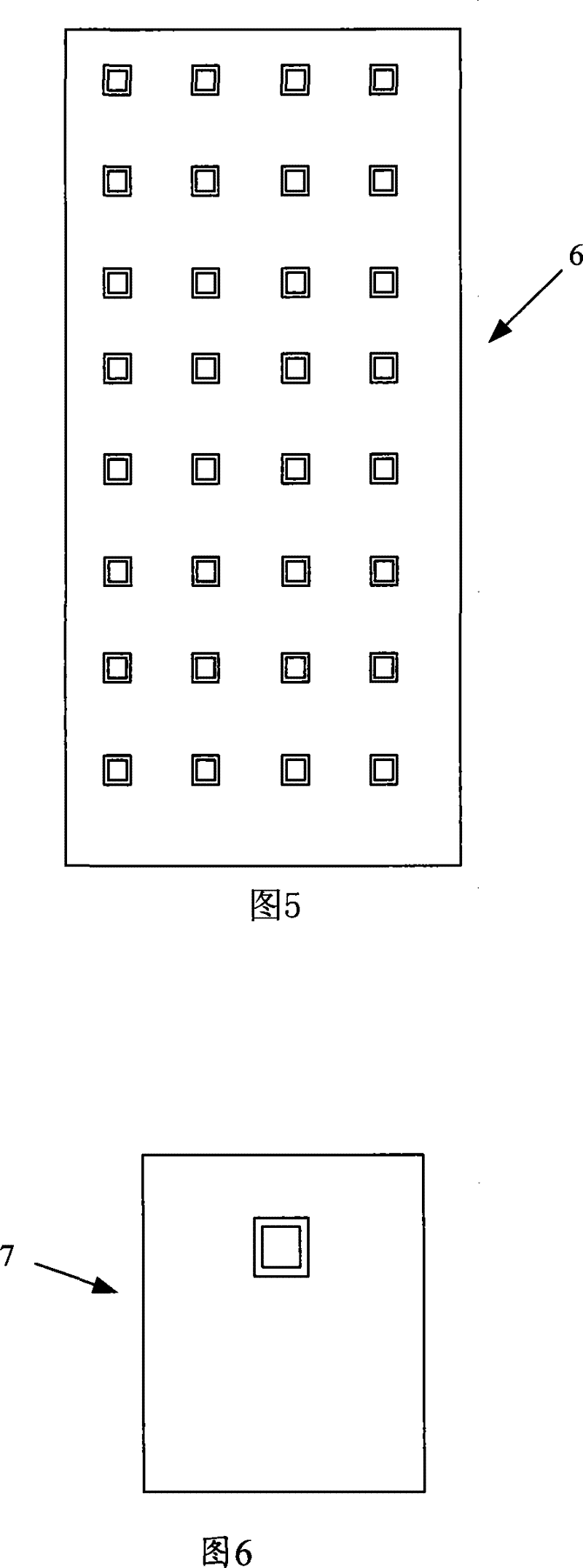

[0029] Step 3: If Figure 4 , 5 The stamped upper and middle base materials 1, 2 and the lower base material 4 are stacked and laminated to form a large card base 6;

[0030] Step 4: If Image 6 As shown, the laminated large card base 6 is pun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com