Machining unit

A technology for machine units and processing tools, which is applied in the direction of metal processing machinery parts, processing machines for manufacturing flat surfaces, metal processing equipment, etc., and can solve complex structures, limited power of processing units, limited speed of edge processing equipment and limited total production, etc. problem, to achieve the effect of reducing weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings.

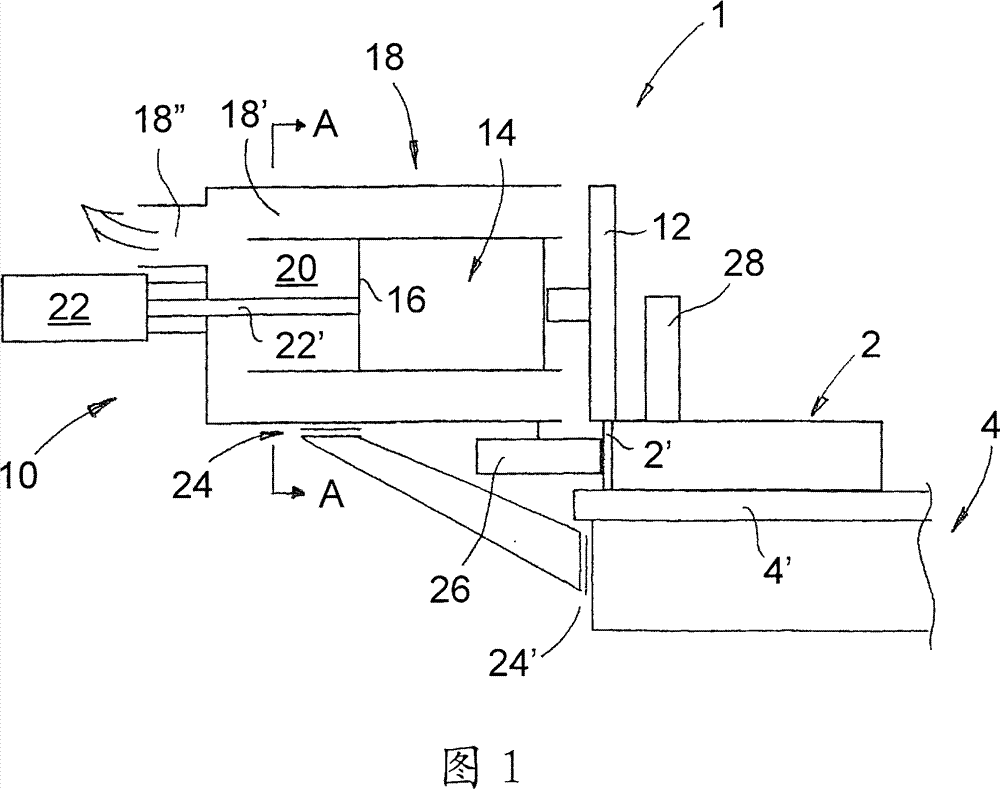

[0018] figure 1 A processing plant 1 as a preferred embodiment of the invention is shown schematically in side section. In this embodiment, the processing device is used for cutting and processing a workpiece 2, for example, the workpiece is at least partially made of wood, wood, plastic, etc., but the invention is not limited thereto. Precisely, in this exemplary embodiment, the processing device 1 is used for processing an edge 2' which is arranged on the narrow side of the workpiece 2 at the time and is glued there, for example. In addition, the workpiece 2 to be processed is transported in the processing device 1 in the direction of travel (perpendicular to figure 1 on the drawing surface), for example on the conveyor belt 4' or on the conveyor table.

[0019] Furthermore, as a preferred embodiment of the invention, the processing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com