Multiple shaft driving mixed power automobile driving system

A hybrid vehicle and multi-axis drive technology, applied in hybrid vehicles, electric vehicles, motor vehicles, etc., can solve the problems of low energy utilization efficiency, complex vehicle structure, and high cost, and achieve energy utilization and control. Flexible, simple structure effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

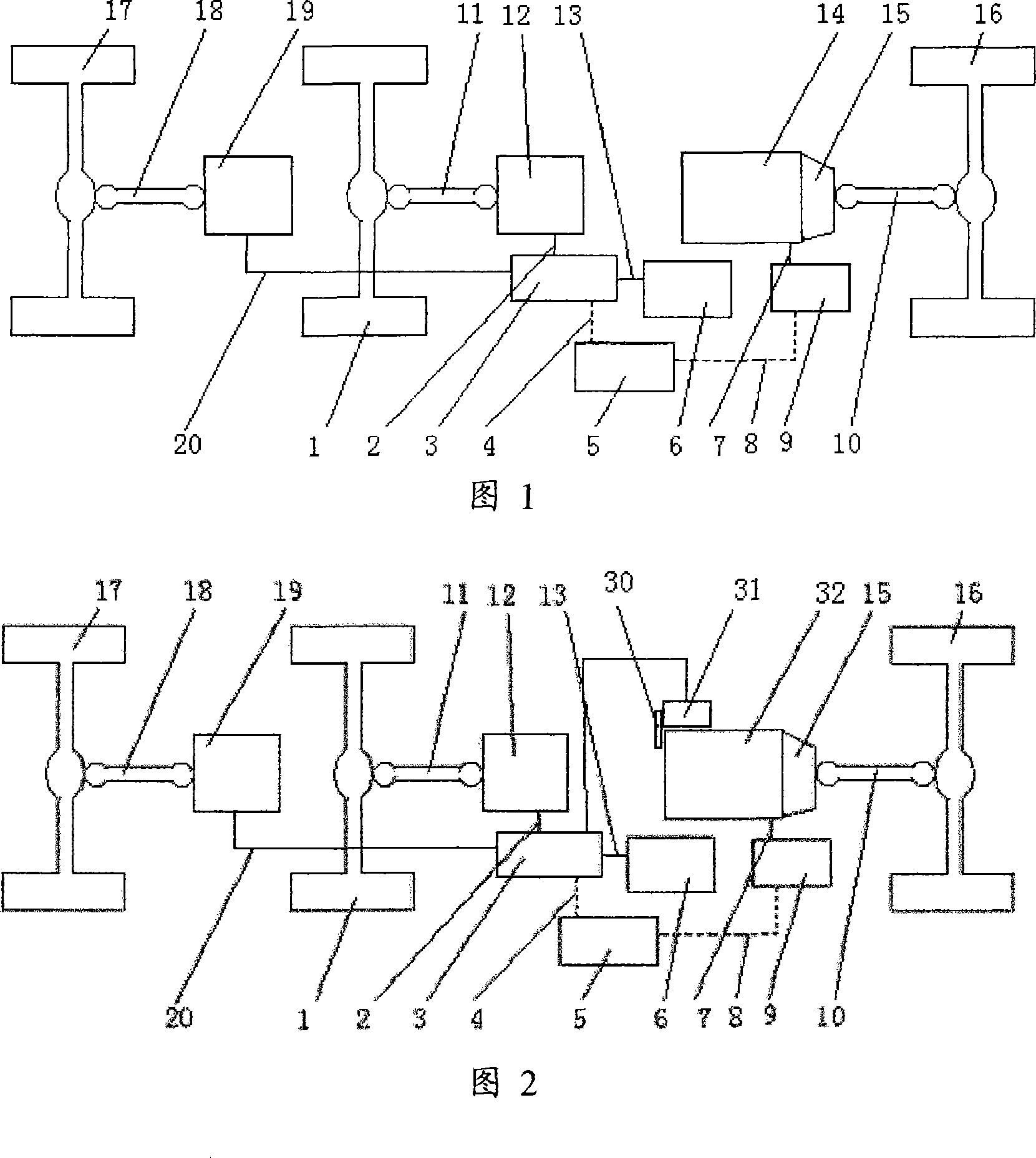

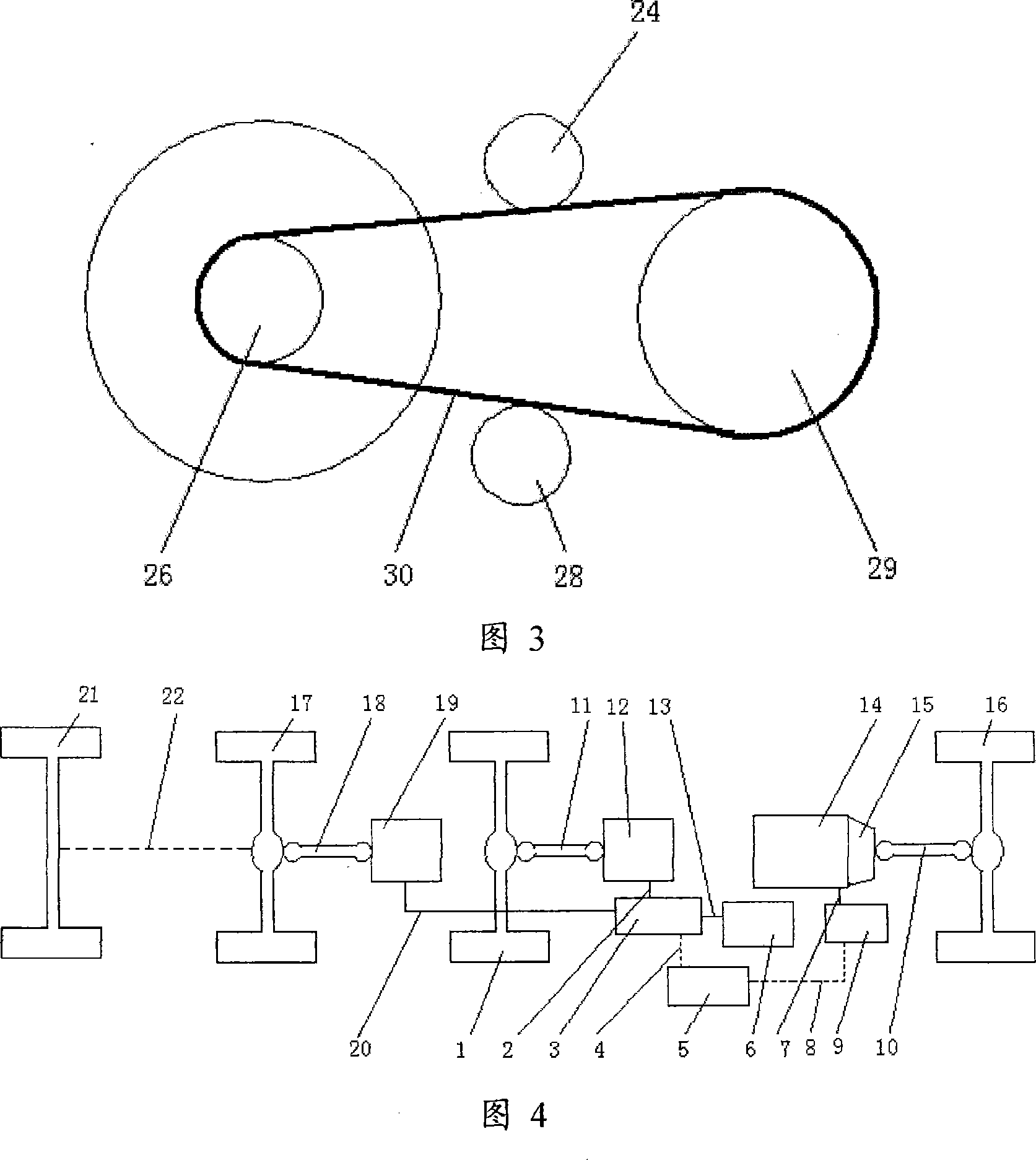

[0021] As shown in Figure 1, the vehicle controller 5 controls the engine controller 9 through the wire harness 8, and the engine controller 9 controls the engine 14 to work through the wire harness 7; the output of the engine 14 is connected to the speed change mechanism 15 and the transmission mechanism 10 to drive the drive shaft 16, The drive shaft 16 drives the wheels to move the vehicle.

[0022] The vehicle controller 5 controls the motor controller 3 through the wiring harness 4, the motor controller 3 controls the driving motor 12 through the wiring harness, drives the driving shaft 1 through the transmission mechanism 11, and the driving shaft 1 is connected to the wheels and rotates to move the vehicle. This is the first electric drive system. The motor controller 3 controls the drive motor 19 through the wiring harness 20, drives the drive shaft 17 through the speed change transmission mechanism 18, and the drive shaft 17 is connected to the wheels; rotating to mak...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com