Single pipe co-well oil-pumping and water-injecting technological system

A process system and single-pipe technology, applied in wellbore/well components, production fluids, earth-moving drilling and other directions, can solve the problems of complex operation, affecting production, inability to adapt to large-displacement water production, etc., to achieve large water production, Avoid the effect of relative rotation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

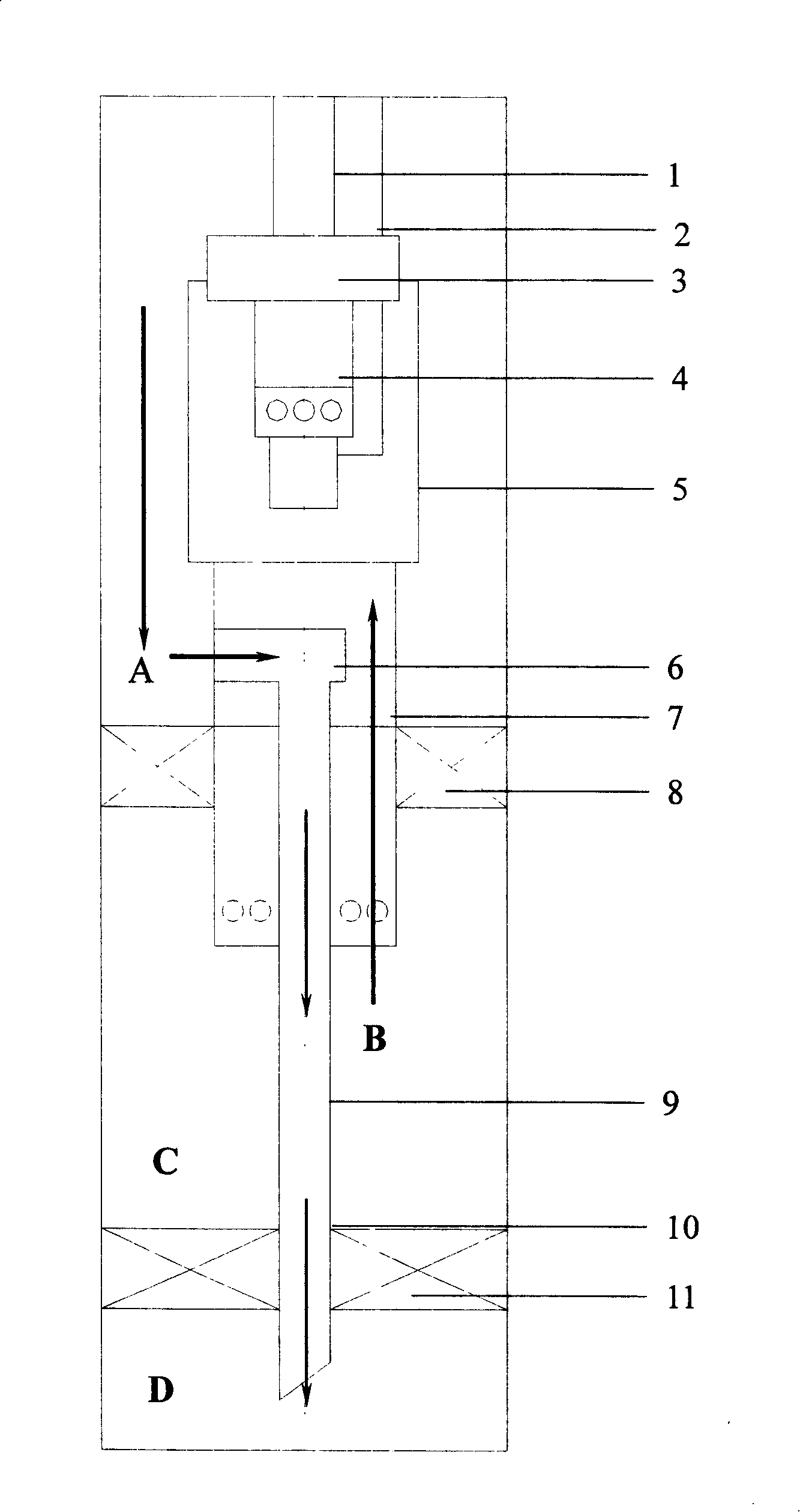

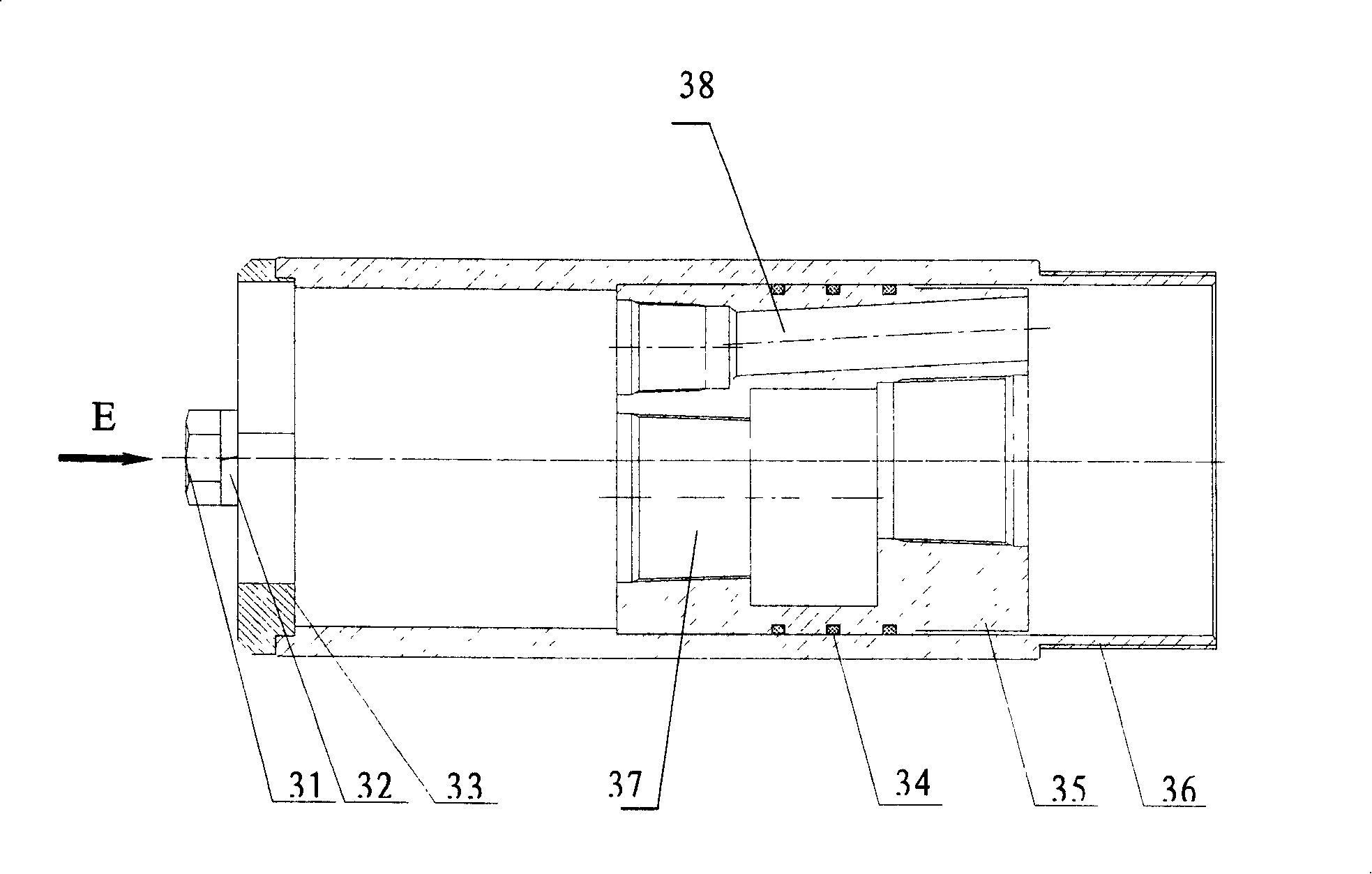

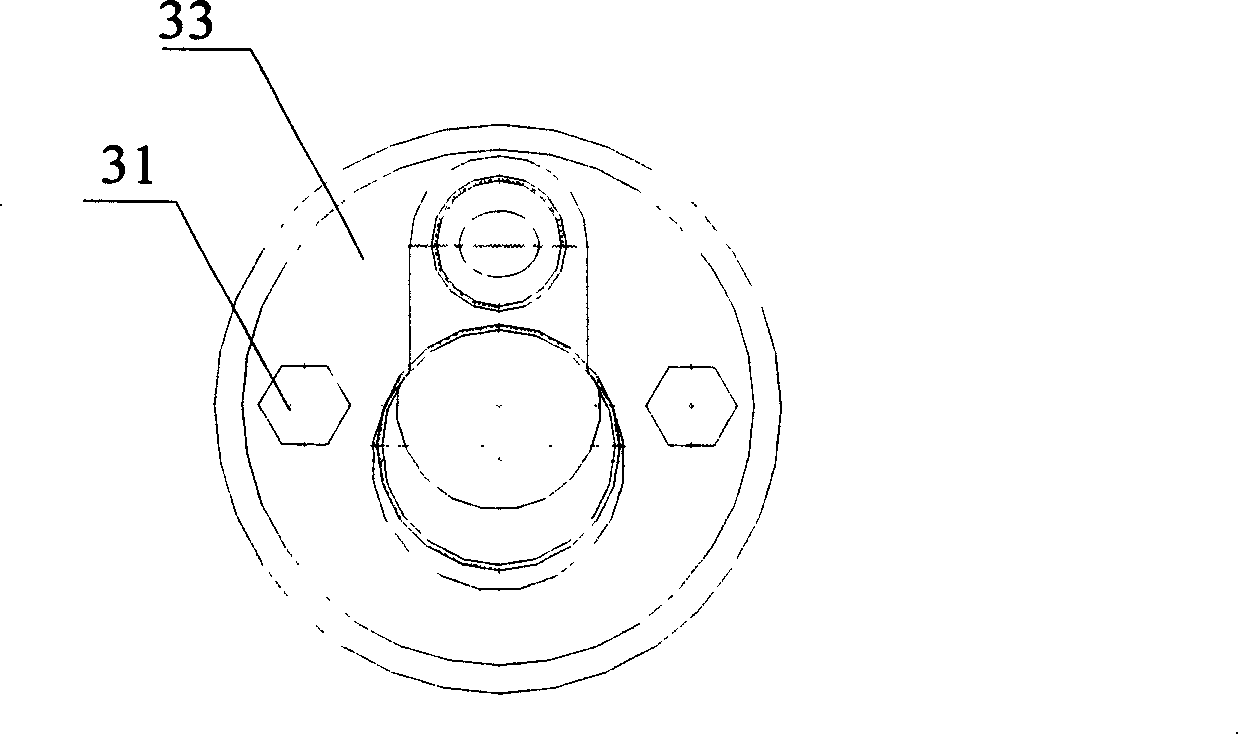

[0025] Such as figure 1 As shown, the technical key point of the single-pipe same well pumping and injection process system of the present invention is to use the large-diameter steel pipe 5 to realize the water collection channel of the large-displacement electric pump, and for the smooth downhole of the large-diameter steel pipe 5 and the electric pump, design The movable joint 3 connecting the large-diameter oil pipe 1 and the electric pump unit 4, the conversion and diversion device 6 for realizing the cross conversion and diversion of the injection and production water channels, and other supporting downhole tools. The large-diameter steel pipe 5 wraps the large-displacement electric pump inside, so that the water collection channel runs from the inside of the large-diameter steel pipe 5, and the injected water passes from the ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com