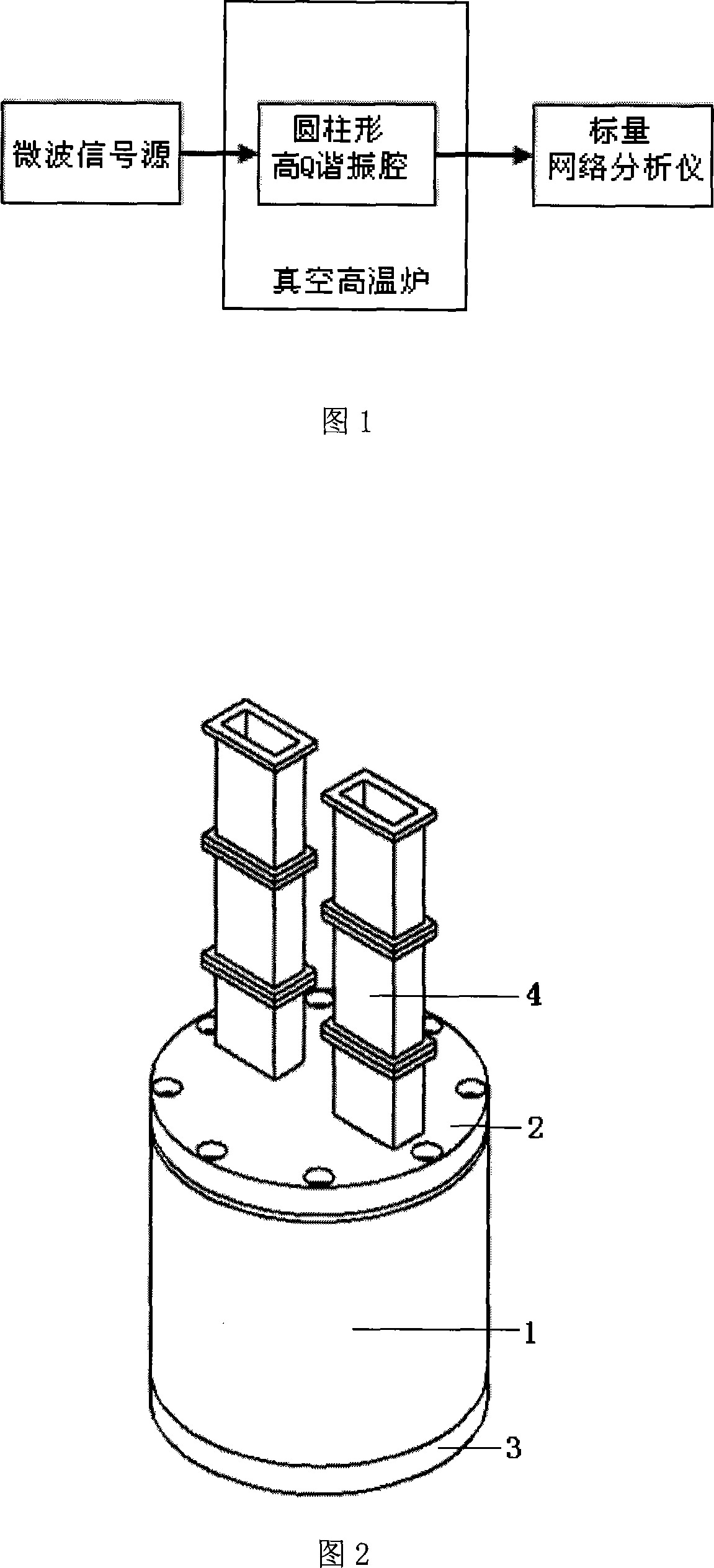

Low consumption dielectric material high temperature complex dielectric constant test device and method

A technology of complex permittivity and dielectric materials, applied in measurement devices, measurement of resistance/reactance/impedance, circuits, etc., can solve problems such as low measurement accuracy, difficulty in adapting to the current testing requirements, and complex testing devices.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

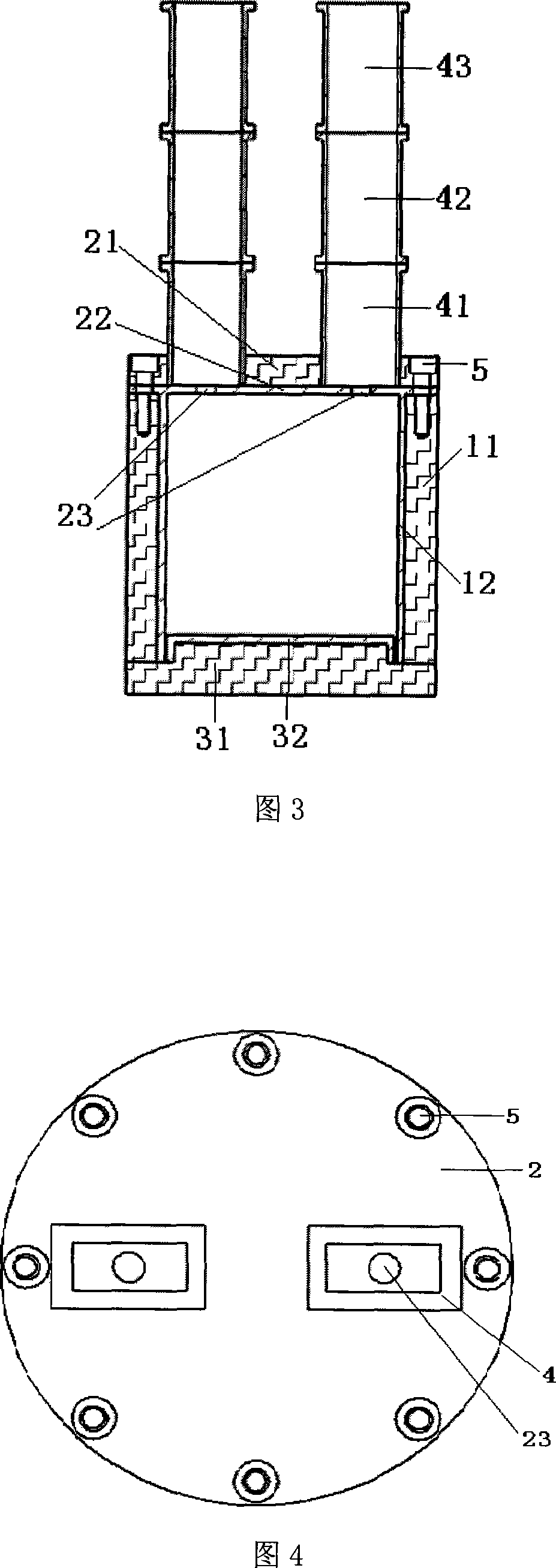

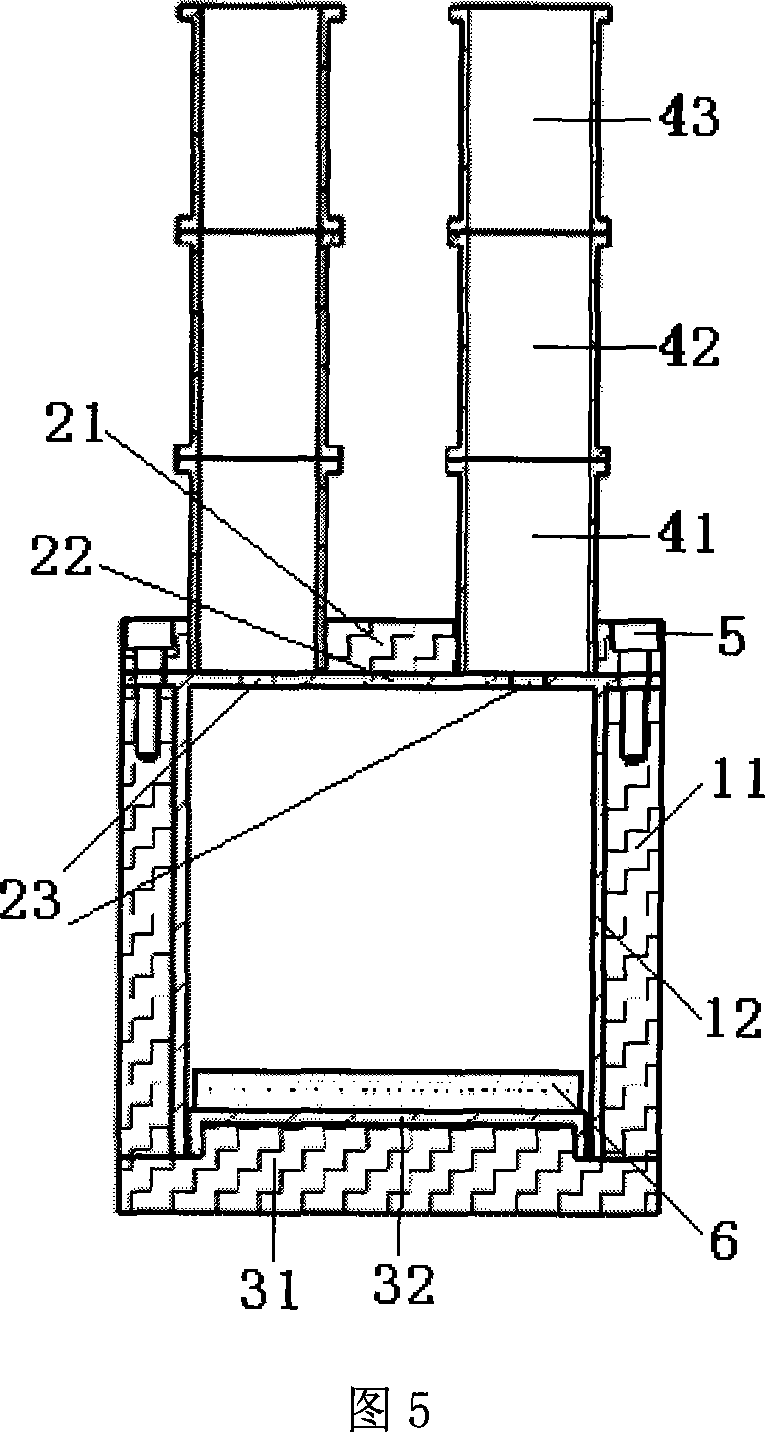

[0052] In the high-temperature complex permittivity testing device for low-loss dielectric materials provided by the present invention, in the cylindrical high-Q resonant cavity, in order to increase the connection between the upper end cover 2 and the cavity barrel 1, and to prevent microwave leakage, a total of 8 Fasten the connecting bolts. The lower end cover 3 and the lower end of the cylindrical cavity 1 are fixedly connected by welding, and the connecting waveguide 4 and the inner layer 22 of the upper end cover are fixedly connected by welding; the high temperature waveguide 41, the heat insulation waveguide 42 and the cooling waveguide 43 can be welded Fixed connection, other methods can also be used, but it should be ensured that there is no microwave leakage. The cavity diameter and cavity length of the entire cylindrical high-Q resonant cavity can be specifically designed according to the test frequency range and the selected working mode of the high-Q cavity.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com