Large-screen definite LED display module and its encapsulation method

A technology of light-emitting diodes and display modules, which is applied in identification devices, cooling/ventilation/heating renovations, instruments, etc., can solve problems such as poor image linearity, limited display accuracy, and inability to watch at close distances, and achieve the goal of solving display problems Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

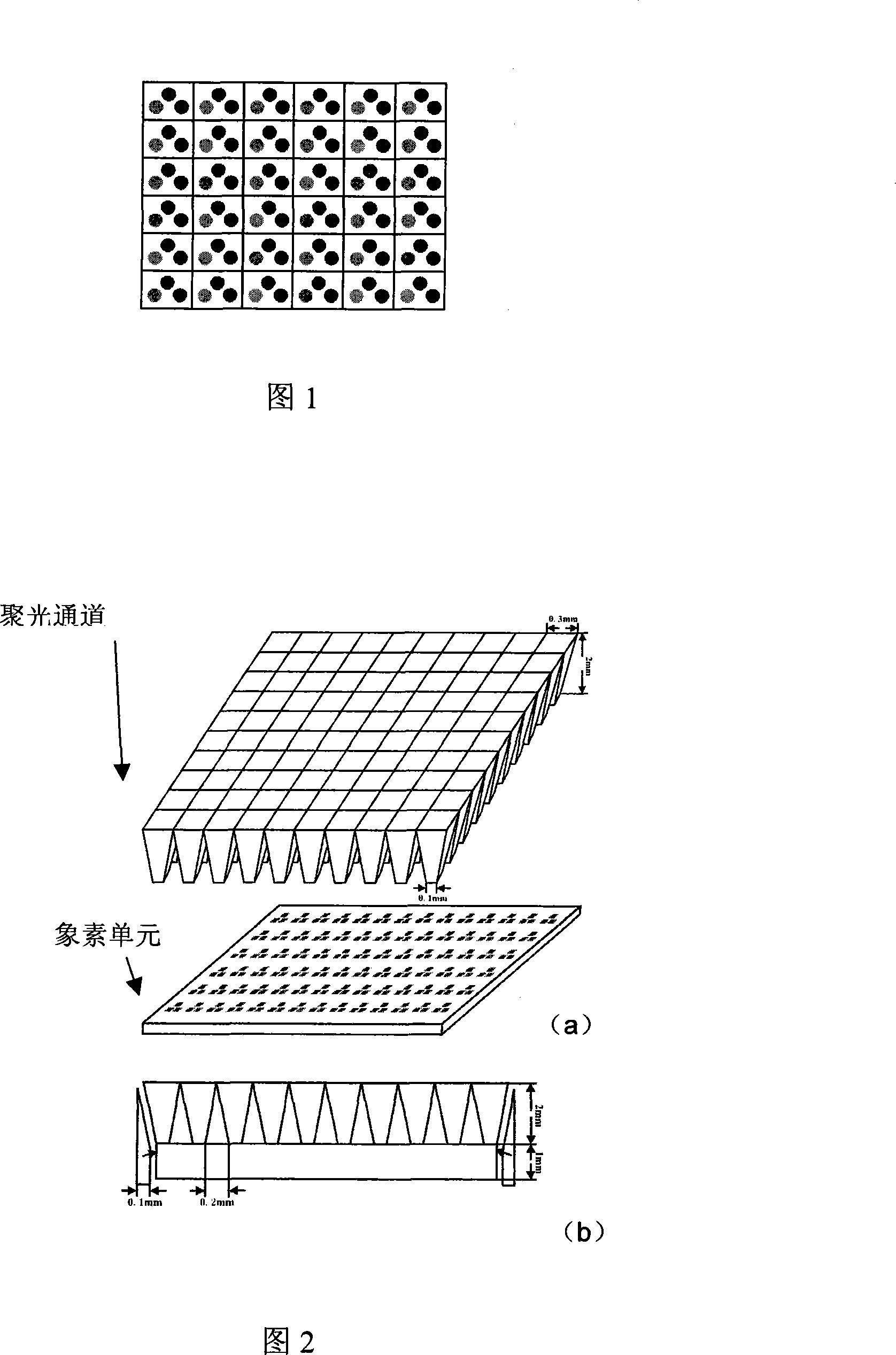

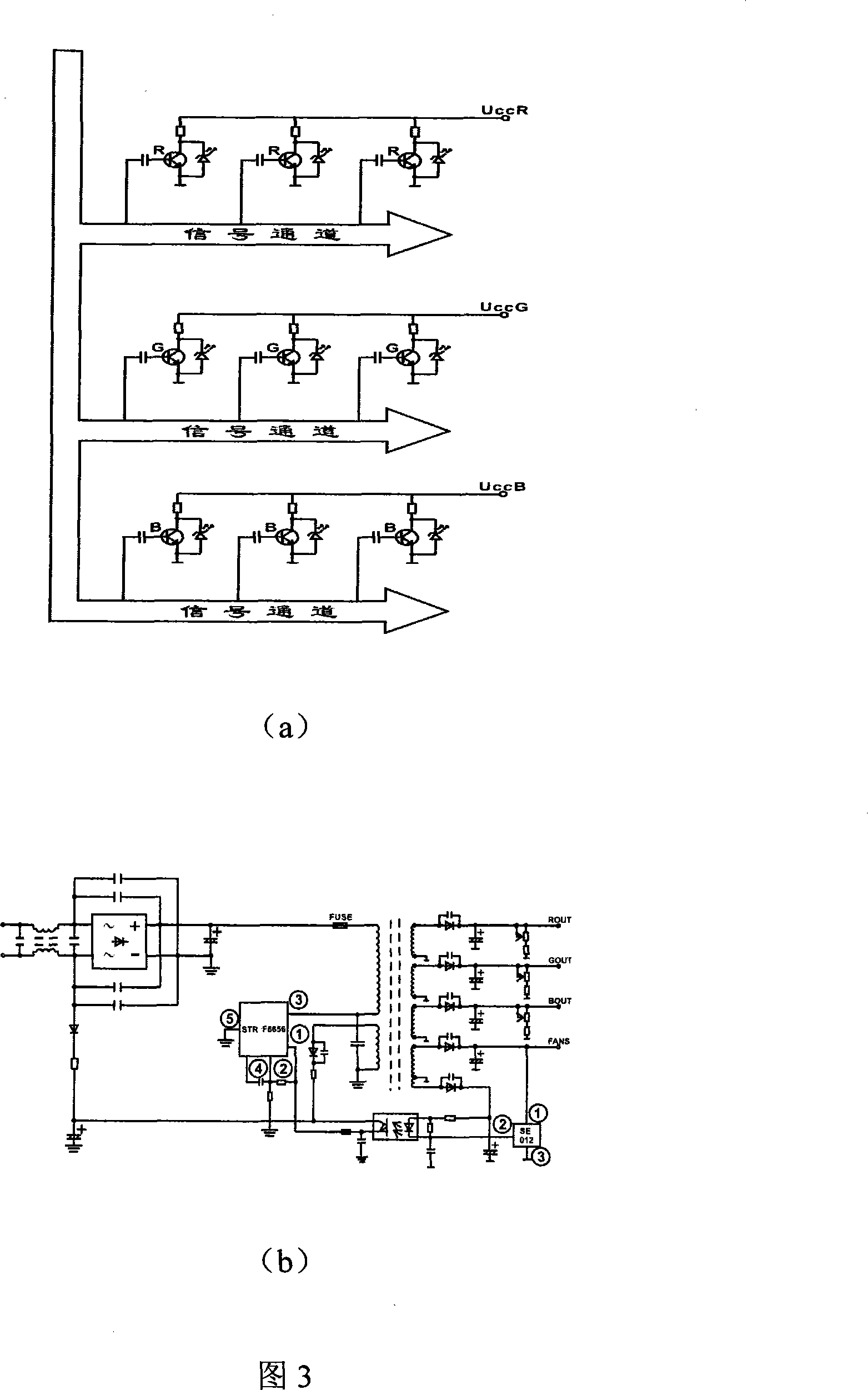

[0030] Need to combine CRT manufacturing, LED manufacturing, IC manufacturing and other processes. First, clean and install the rack. When installing the rack, the tube cores need to be arranged according to the font (every 0.2mm in a group, and the diameter of each group is controlled at 0.1mm); then press welding and dispensing, follow the practice of white LED when dispensing, Put phosphor powder on each LED, arrange each group according to the three primary colors of R / G / B, and then wire (including the matrix); 0.1mm), after the concentrator is fixed, line the bottom of the PCB with 1mm thick heat-conducting ceramics (reserve the interface space), and finally make the interface.

[0031]After the module is manufactured, paste the radiator (2mm thick grid-shaped aluminum sheet) on the module with thermal conductive adhesive, then install the cooling fan group on the radiator in the upward direction of heat dissipation, and then install the temperature sensor on the back of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com