A high price/performance ratio high-power IGBT module

A high-power, cost-effective technology, applied in the direction of output power conversion devices, electrical components, etc., can solve the problems that the parallel design of IGBT modules has not been deeply involved, and the module efficiency and life have not reached the optimum, so as to reduce the overall design difficulty and reduce the Cost and selection difficulty, effect of compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

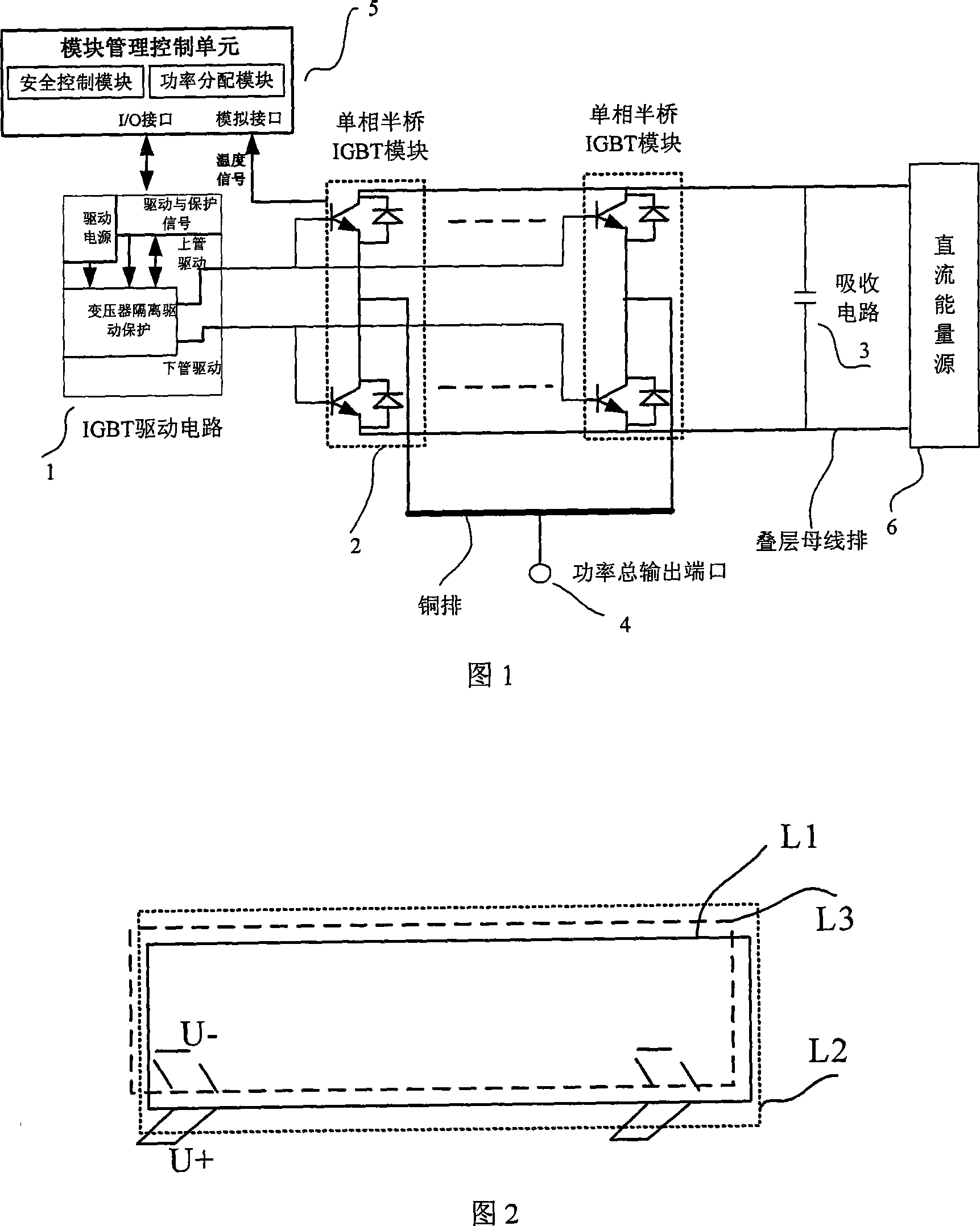

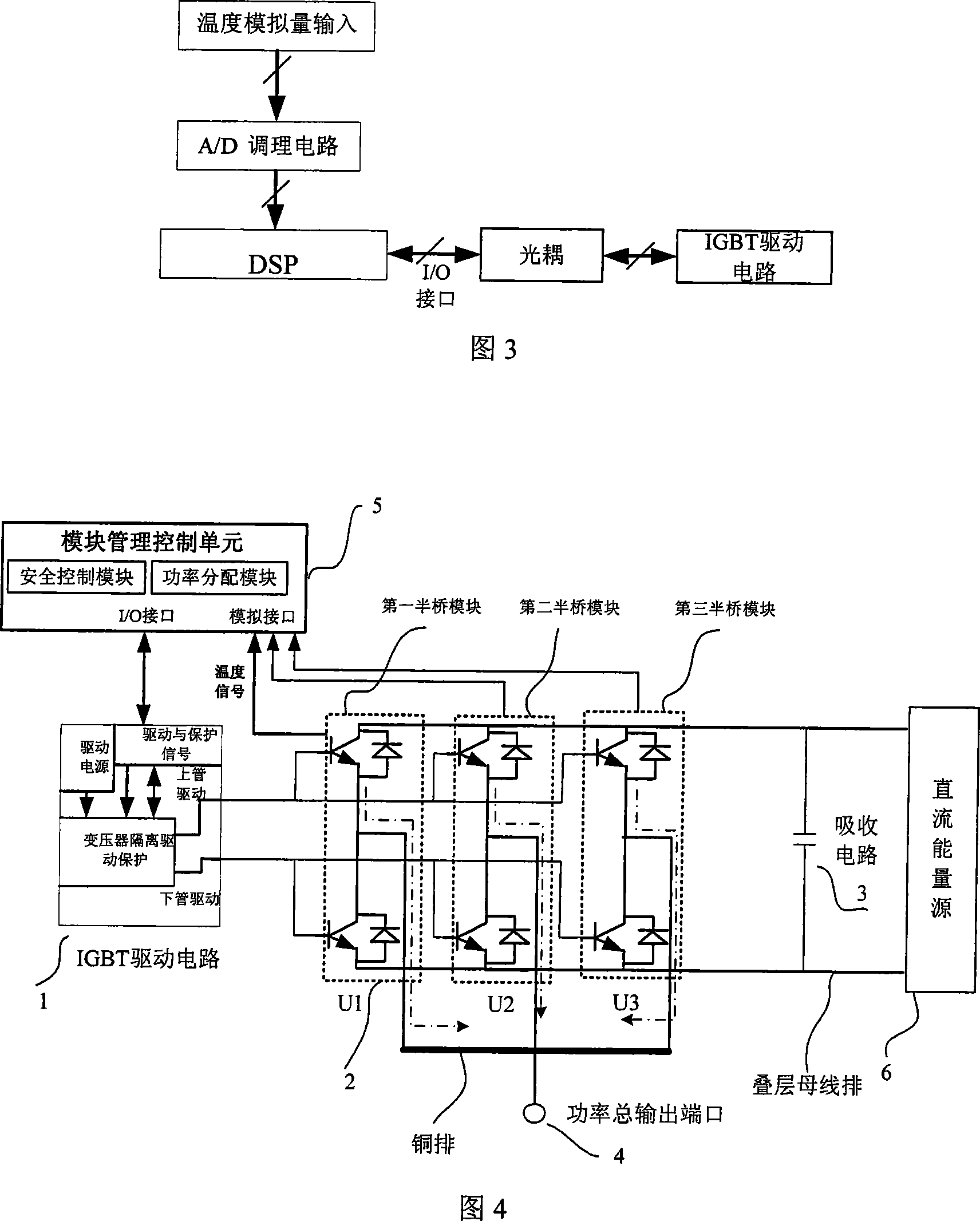

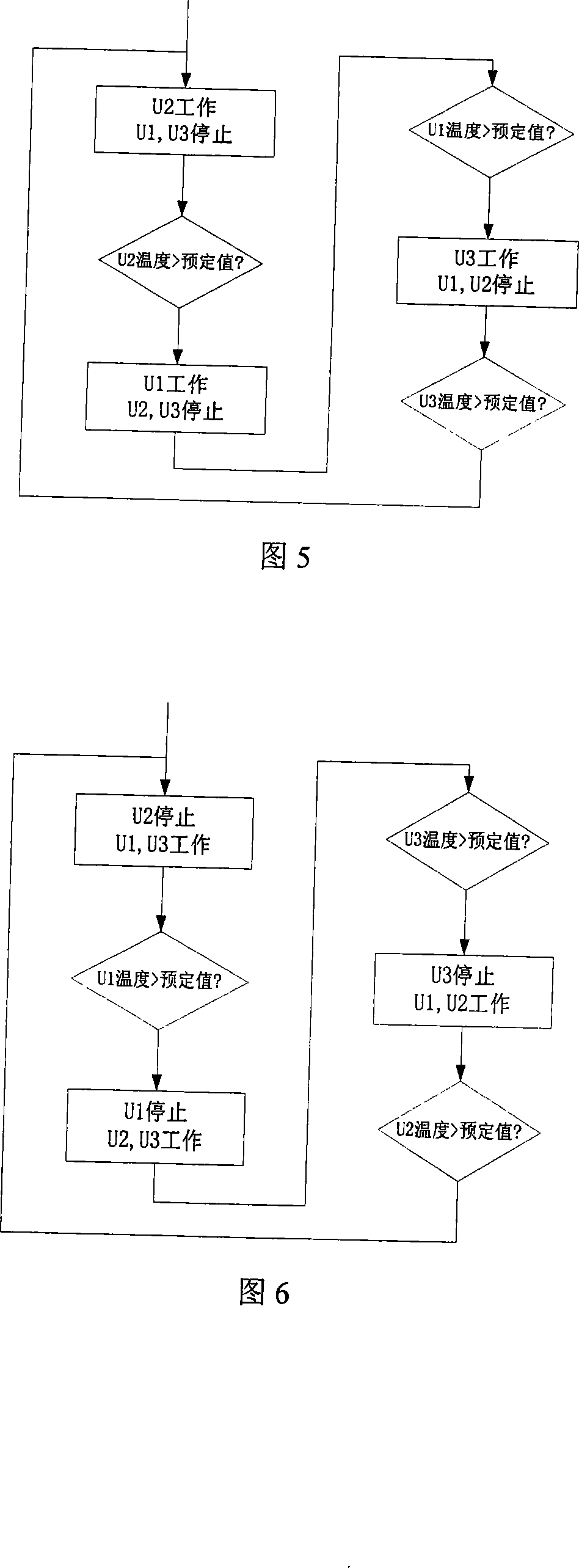

[0021] As shown in Fig. 1, the high-power single-phase half-bridge IGBT module of the present invention is mainly composed of a module management control unit, n (n≥2) single-phase half-bridge IGBT modules, an IGBT drive circuit 1, an absorption circuit 3 and a cooling system. n single-phase half-bridge IGBT modules 2 are connected in parallel to form a high-power single-phase half-bridge IGBT module, which is powered by a DC energy source 6, and the load is connected to the total power output port 4. Drive circuit 1 and sink circuit 3.

[0022] Each single-phase half-bridge IGBT module consists of two IGBTs and anti-parallel freewheeling diodes. There are two types of IGBT devices: NPT type and PT type. The conduction voltage of NPT type IGBT has a positive temperature coefficient, which is more suitable for parallel connection. operate. When selecting parallel IGBT devices, NPT type IGBT devices should be selected, and the same batch of devices should be used as much as pos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com