In-tray inspection apparatus and method of semiconductor package

An inspection method and inspection equipment technology, applied in the direction of single semiconductor device testing, measuring devices, instruments, etc., can solve problems such as increased operating costs and difficulties, and achieve the effects of improving efficiency and reducing the time required for inspection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings so that those skilled in the art can easily understand and implement the present invention.

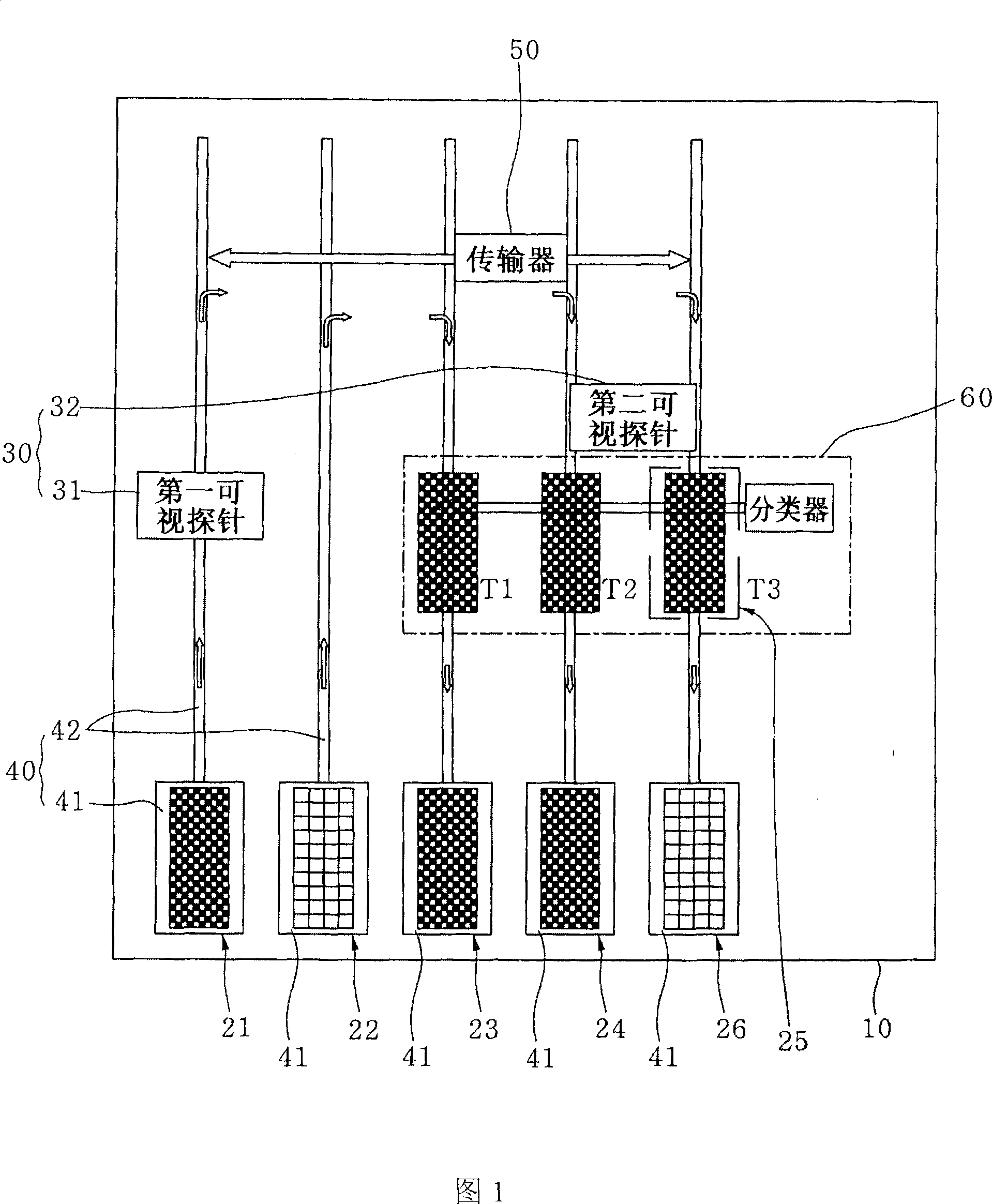

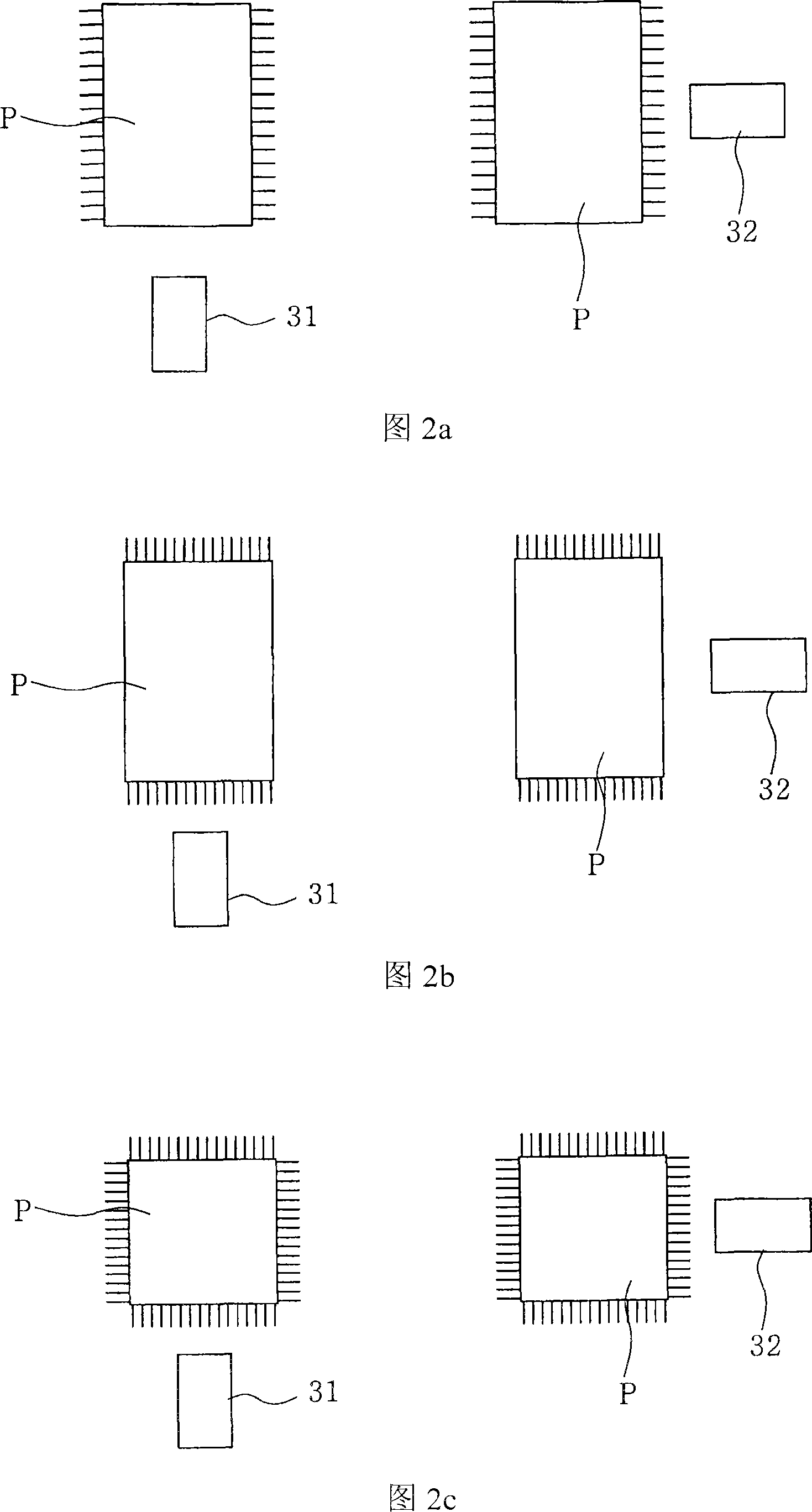

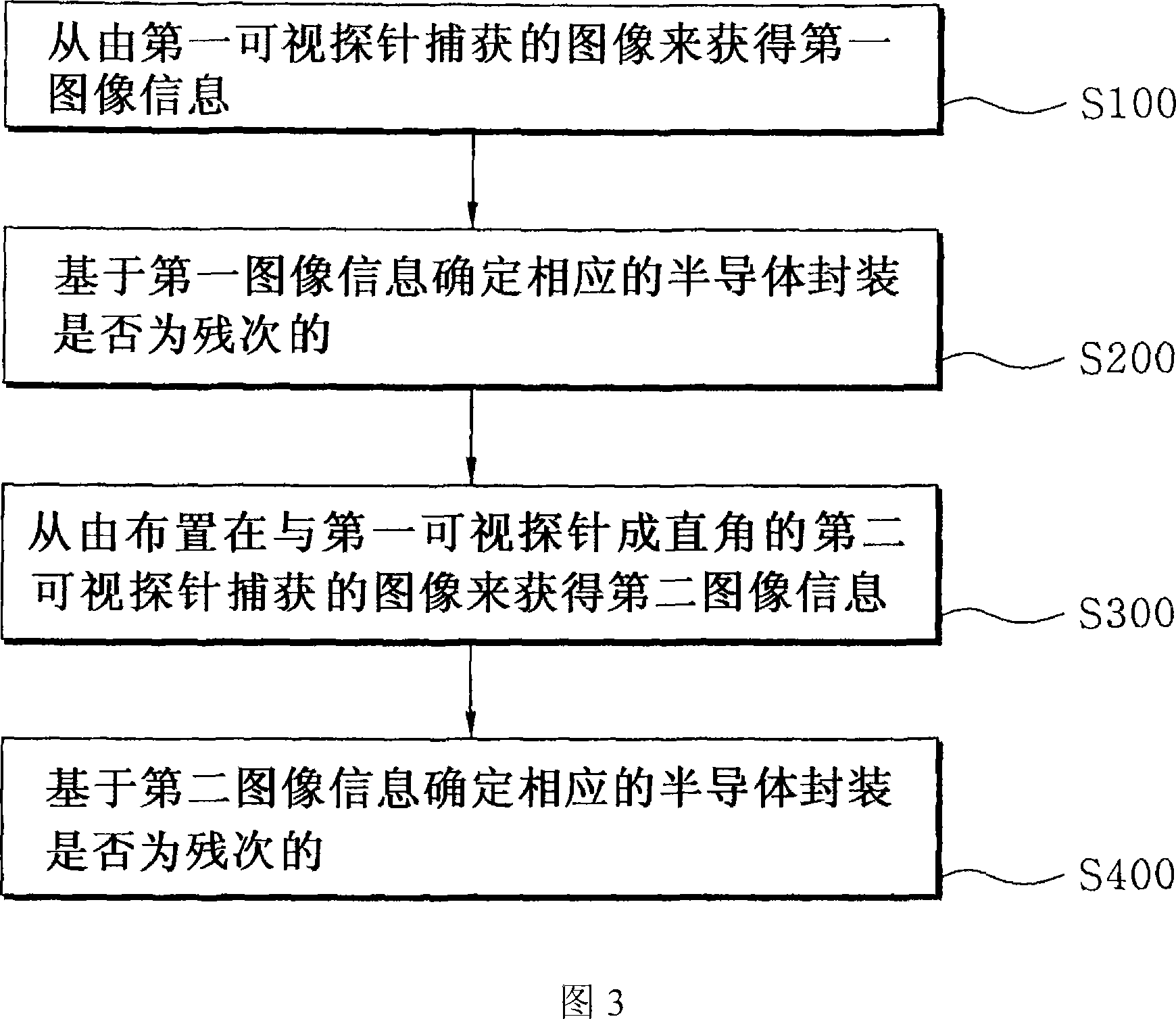

[0023] FIG. 1 is a schematic diagram showing an inspection device according to a preferred embodiment of the present invention, and FIG. 2 is a diagram showing an arrangement of visual probes of the inspection device according to a preferred embodiment of the present invention.

[0024] As shown in FIG. 1 , an in-disk inspection apparatus according to a preferred embodiment of the present invention includes an inspector 30 disposed on a transfer path of a reel (hereinafter referred to as "inspected object") for accommodating semiconductor packages. to photograph the appearance of the object, and the central controller (not shown) is used to compare the image information of the object obtained by the inspector 30 with reference image information of a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com