Skewer processor

A technology for processing machines and meat skewers, which is applied in the fields of processing meat, slaughtering, food science, etc., can solve the problems of different sizes of cut meat pieces, affecting the barbecue effect, and high labor intensity, and achieves uniform thickness and size, and the barbecue effect is achieved. Good, good processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with accompanying drawing:

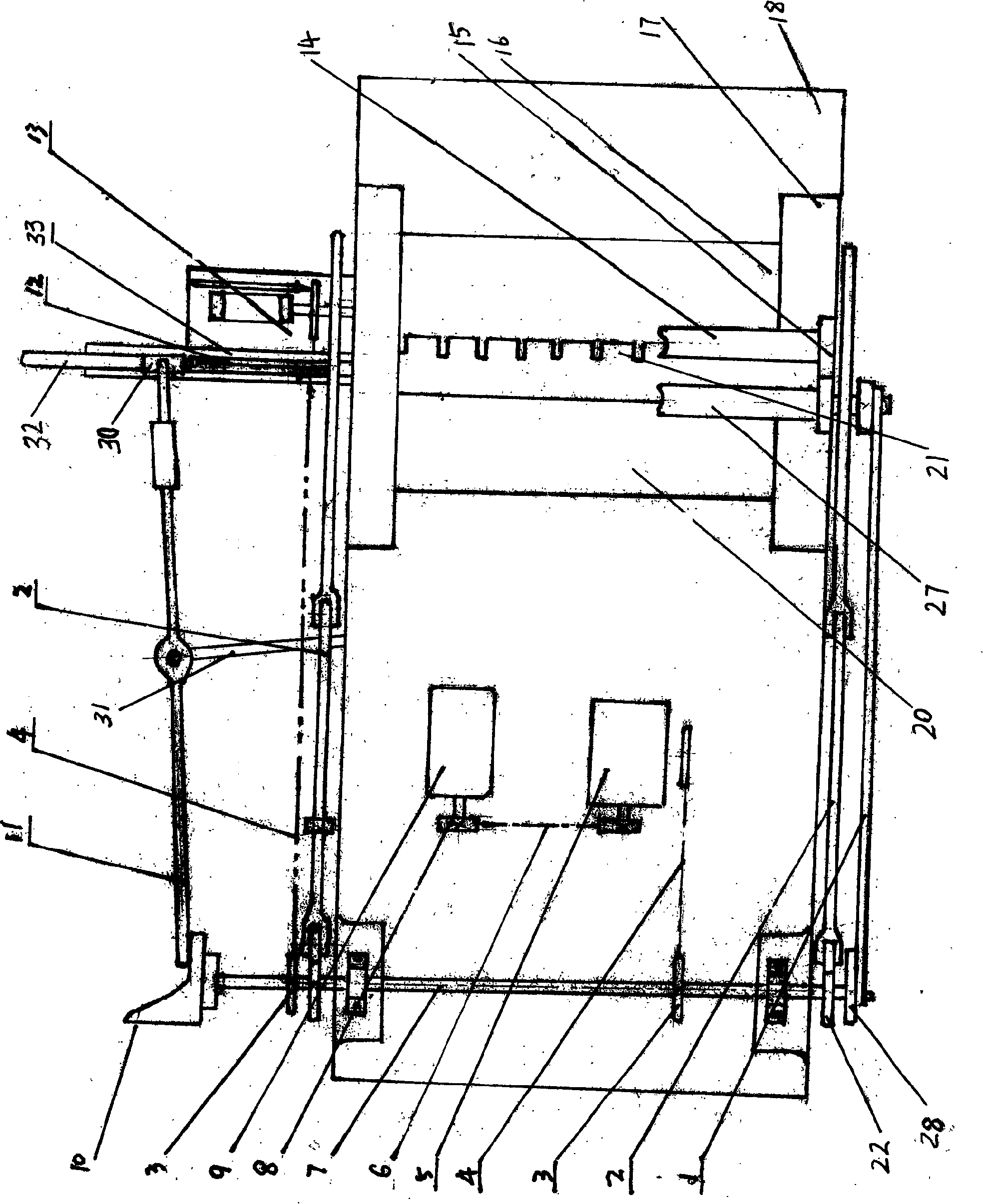

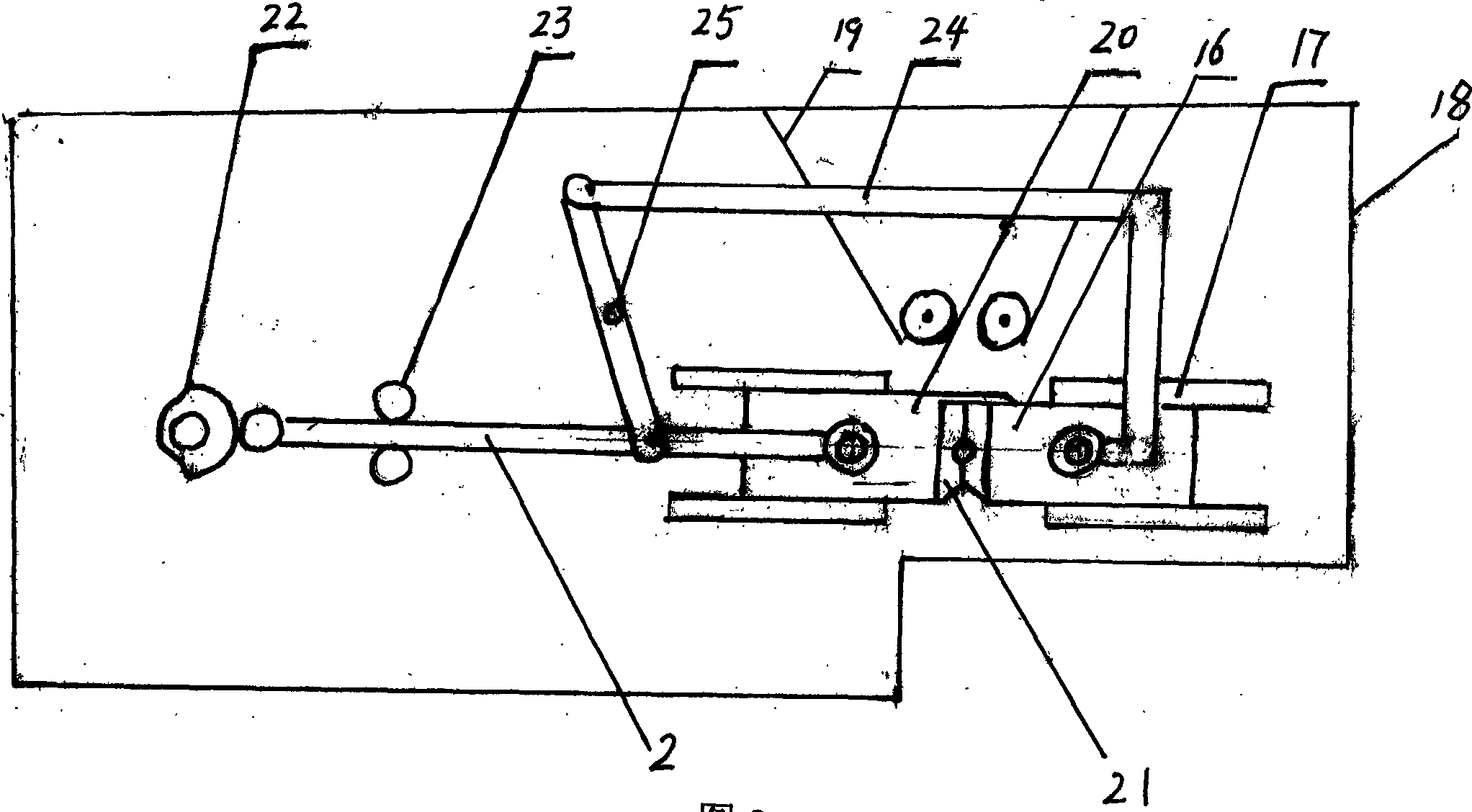

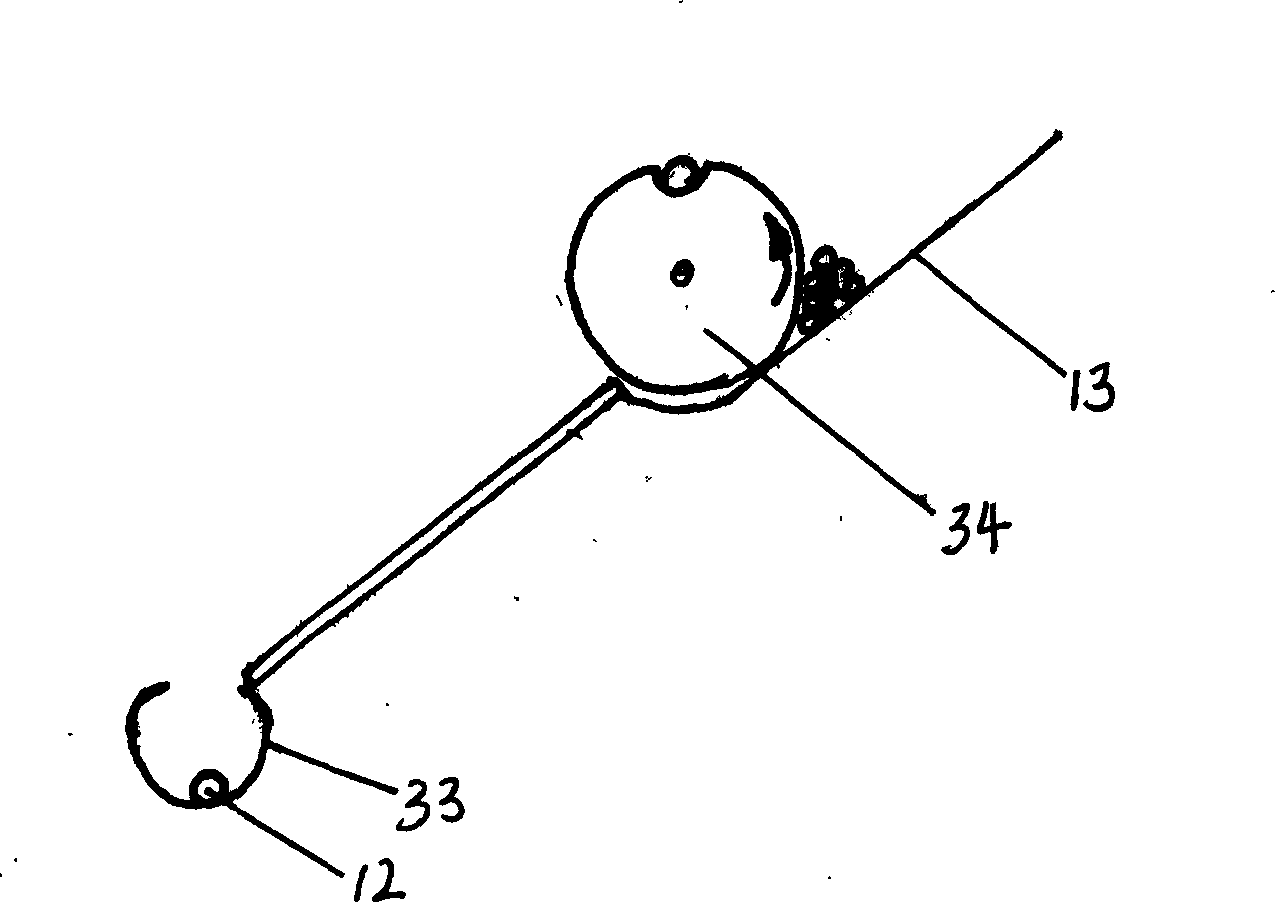

[0020] As shown in the accompanying drawings, a meat skewer processing machine is provided with a body 18, which is provided with a meat material box 19, a motor 9, a gearbox 5, a transmission shaft 7, and the structure and interconnection of the motor 9 and the gearbox 5 Relation is identical with prior art, this does not go into details, body 18 both sides are respectively provided with cutter guide rail 17, also can be provided with cutter guide rail 17 on one side of body 18, and cutter guide rail 17 is respectively provided with push knife slide block 20 and the broach slider 16, the push knife slider 20 and the broach slider 16 are provided with several blades 21 that are mutually dislocated, and the push knife slider 20 and the broach slider 16 can be connected through the connecting rod and the transmission shaft 7 respectively. The eccentric device on the body can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com