Addition type cross-linking vulcanized polydisiloxane elastomer

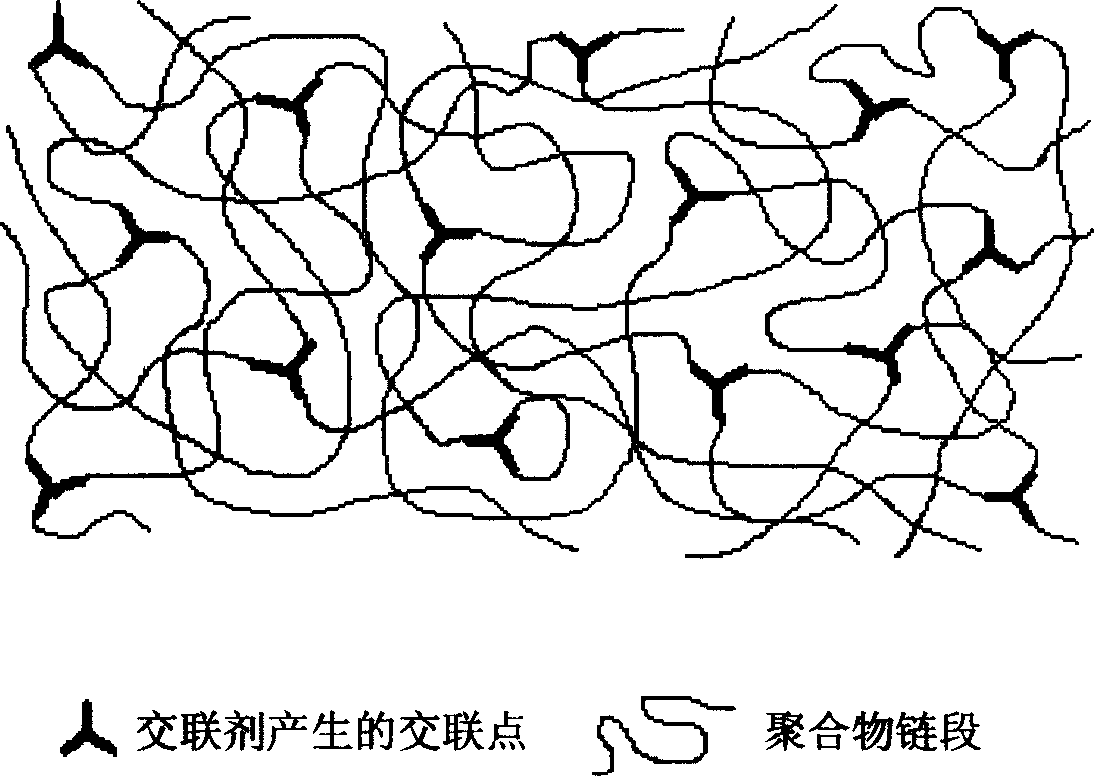

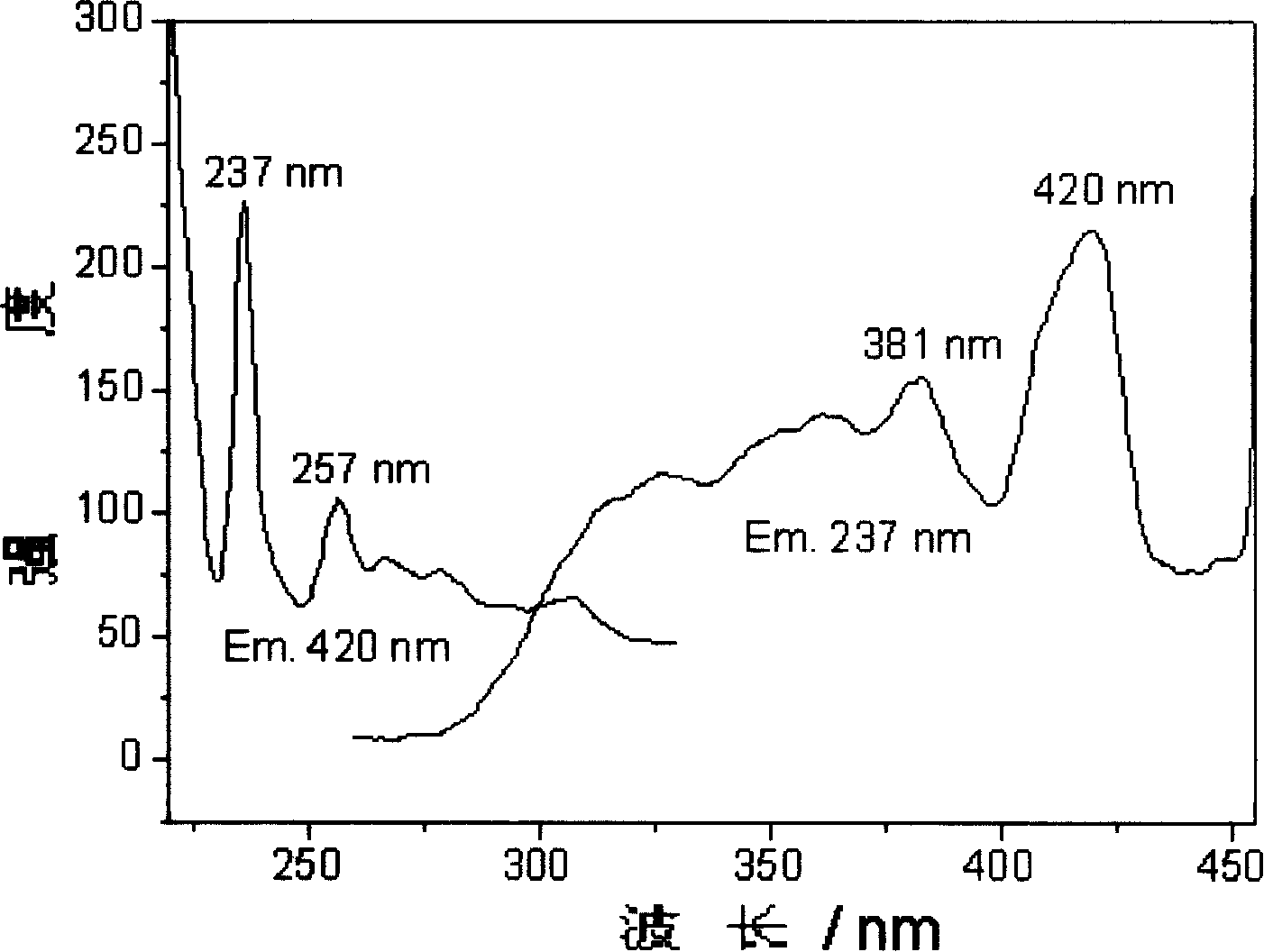

A technology of polydisiloxane and polysiloxane, which is applied in the field of polydisiloxane polymer elastomer and its preparation, can solve the problems that the preparation method of new silicone elastomer materials has not been reported, and achieve unique light Luminescent properties, good mechanical properties, simple vulcanization and cross-linking process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] 100 parts by weight of polydisiloxane;

[0020] 8 parts by weight of methyl triallyl silane coupling agent;

[0021] Chloroplatinic acid catalyst (calculated as platinum) 0.002 parts by weight.

[0022] Mix the measured amount of polydisiloxane or methyl triallyl silane coupling agent (crosslinking agent) and chloroplatinic acid catalyst evenly, then transfer and pour into the mold, and react at a temperature of 25°C for 1 to 2 hours After 24 hours, it is completely vulcanized, and the elastic body with certain hardness and certain mechanical properties is prepared. The results of the mechanical properties are as follows: tensile strength: 1.32MPa, elongation at break: 180%, Shore A Hardness: 48.

Embodiment 2

[0024] 50 parts by weight of polydisiloxane;

[0025] 50 parts by weight of polysiloxanes containing silicon-hydrogen bonds and hydrocarbon groups in the side chain;

[0026] 35 parts by weight of vinyl polysiloxane;

[0027] Chloroplatinic acid catalyst (calculated as platinum) 0.002 parts by weight.

[0028] Mix the measured amount of polydisiloxane and the mixture of polysiloxane containing silicon-hydrogen bonds and hydrocarbon groups in the side chain, vinyl polysiloxane, and chloroplatinic acid catalyst, and transfer it into the mold after mixing evenly. After reacting at 25°C for 1 to 2 hours, it will be surface dry, and after 24 hours, it will be completely vulcanized, and an elastomer rubber with a certain hardness is prepared. The results of the mechanical properties are as follows: tensile strength: 3.68MPa, elongation at break: 285%, Shore A hardness: 30.

Embodiment 3

[0030] 5 parts by weight of polydisiloxane;

[0031] 95 parts by weight of polysiloxanes containing silicon-hydrogen bonds and hydrocarbon groups in the side chain;

[0032] 30 parts by weight of vinyl polysiloxane;

[0033] Chloroplatinic acid catalyst (calculated as platinum) 0.002 parts by weight.

[0034] Mix the measured amount of polydisiloxane and the mixture of polysiloxane containing silicon-hydrogen bonds and hydrocarbon groups in the side chain, vinyl polysiloxane, and chloroplatinic acid catalyst, and transfer it into the mold after mixing evenly. After reacting at 25°C for 1 to 2 hours, it will be surface dry, and after 24 hours, it will be completely vulcanized, and an elastomer rubber with a certain hardness is prepared. The results of the mechanical properties are as follows: tensile strength: 9.82MPa, elongation at break: 620%, Shore A hardness: 32.

[0035]Similarly, other embodiments can also be provided according to the technical solution provided by the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap