Air flow filling and sucking type foundation draining method

A drainage method and foundation technology, applied in infrastructure engineering, soil protection, construction, etc., can solve the problems of large pressure difference, the drainage effect cannot reach the expected effect, and the air pressure is small, so as to ensure the treatment quality and improve the drainage effect. , Easy to use and labor-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

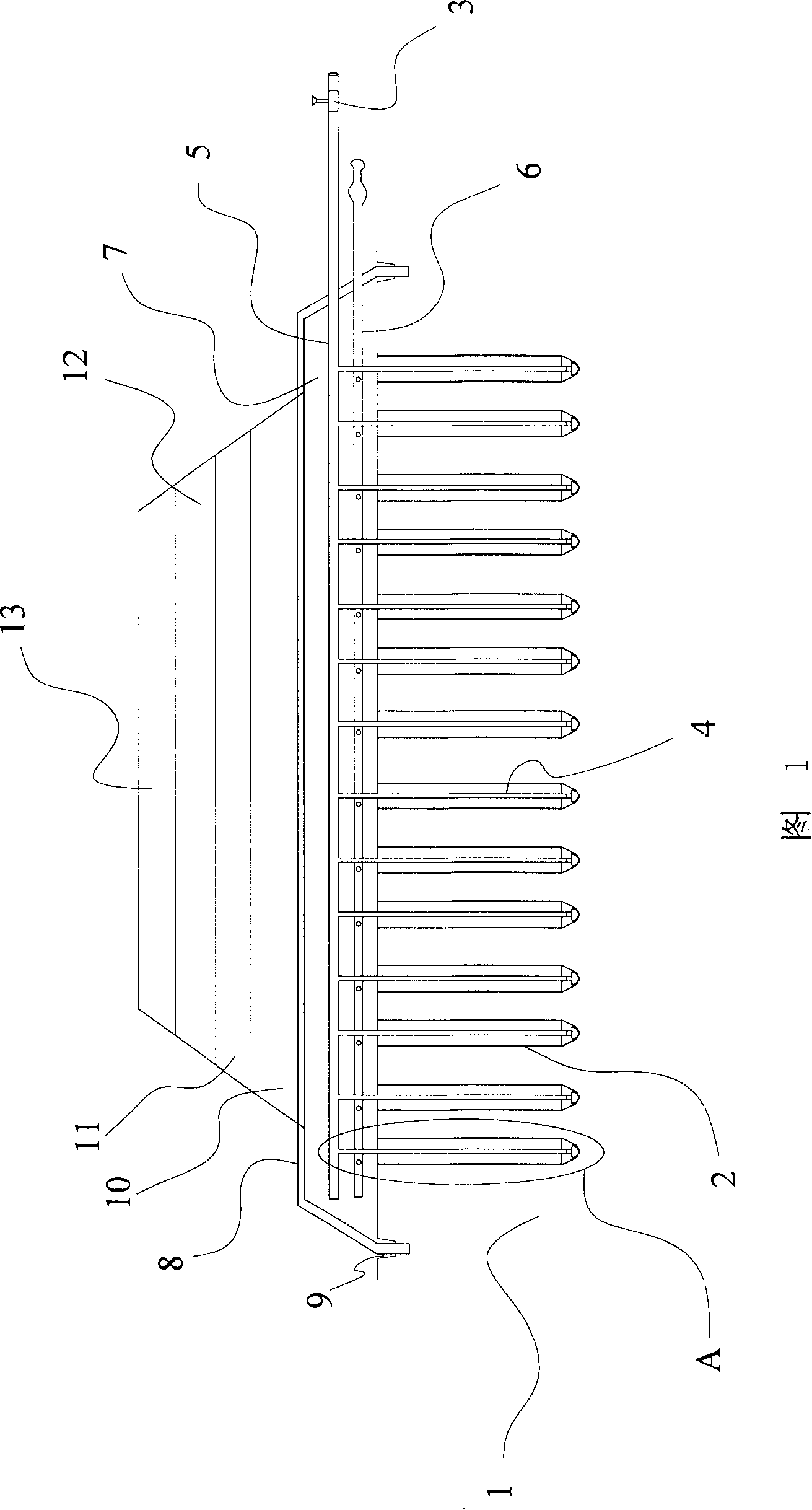

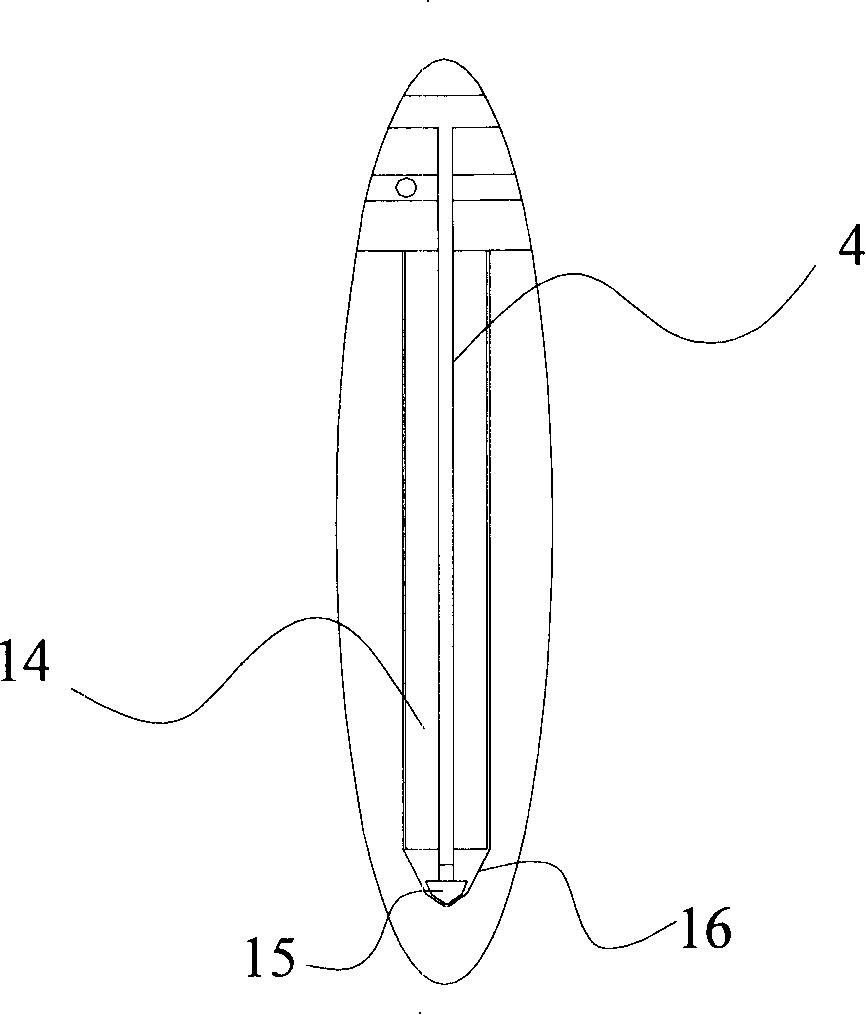

[0024] The implementation status of the airflow suction type foundation drainage method shown in Figures 1 and 2 is to embed a hollow pipe 4 of the same height in the drainage body 2 in advance, and the drainage body 2 can use the existing drainage board, and its core body Cut off a section from the lower end of 14 to expose the hollow tube 4, connect the auxiliary part 15 at the lower end of the hollow tube 4, then fasten the bottom of the filter membrane 16 or turn up and wrap the lower end of the core body 14 to form a filter membrane bag. The core body 14 can use the plastic plate or the plastic mesh plate that has drainage channel. The drainage channel can be a vertical guide groove on the plastic plate or a gap between mesh wires.

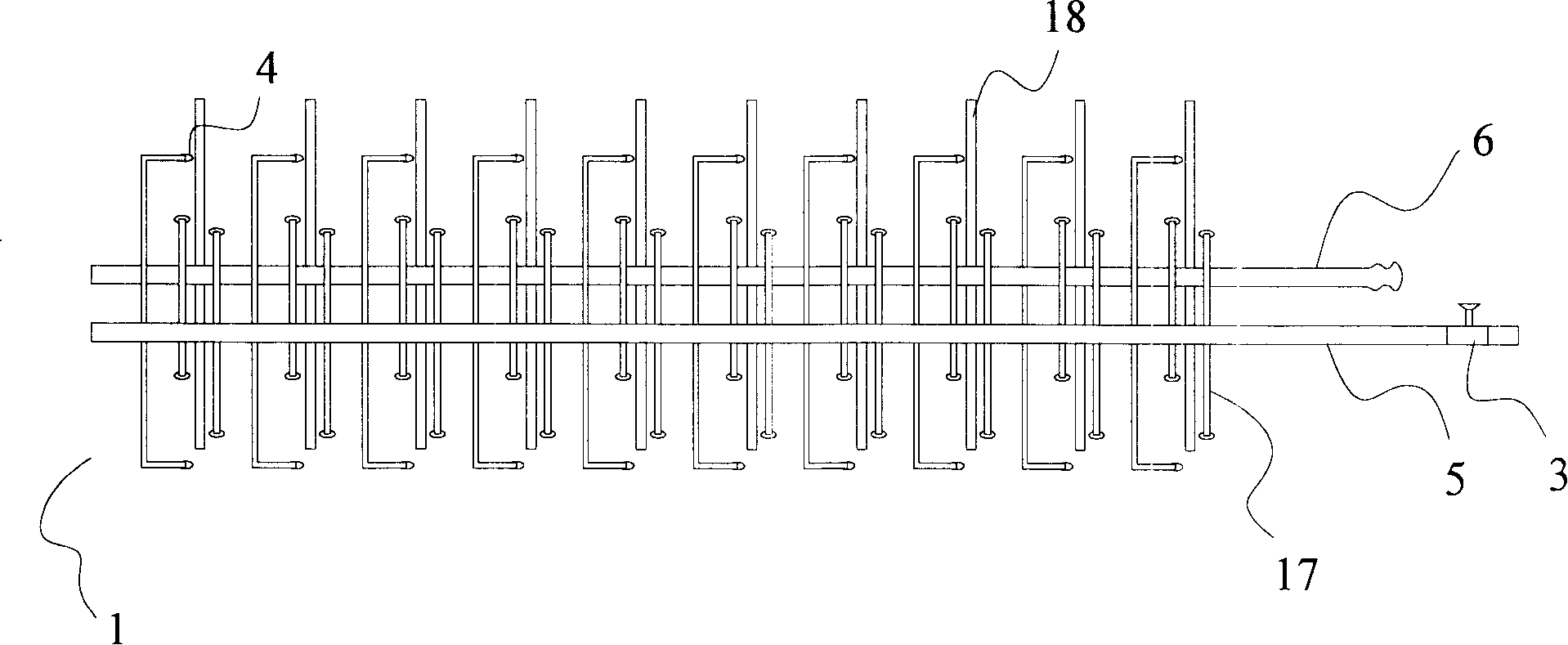

[0025] Then a plurality of drainage bodies 2 are vertically inserted into the foundation 1, and the upper ends of the hollow pipes of all drainage bodies 2 are connected with the intake main pipe 5 to form an intake pipe network, so that the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com