Backlight module, reflector plate structure and LCD device

A technology of backlight modules and reflectors, applied in static indicators, optics, instruments, etc., can solve problems affecting the display quality of liquid crystal displays, affecting the quality of liquid crystal displays, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

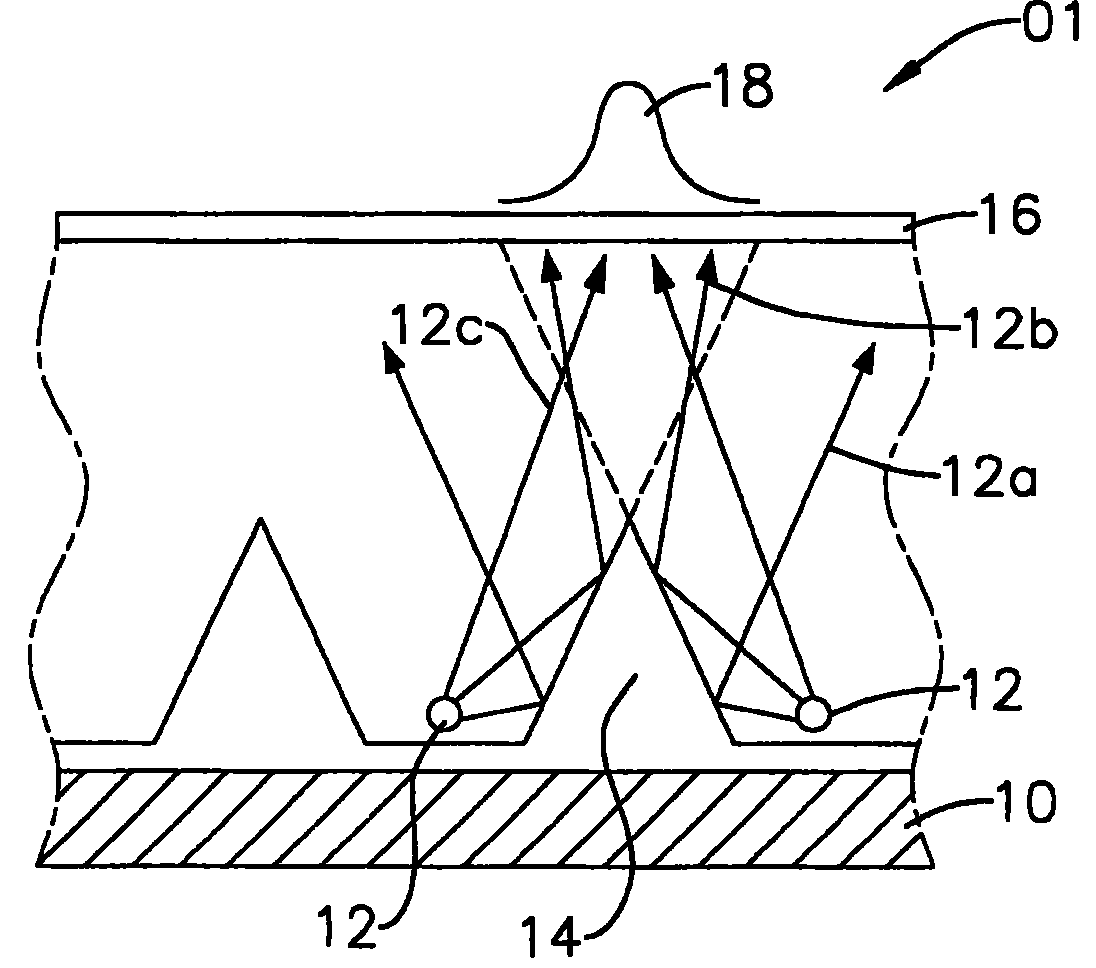

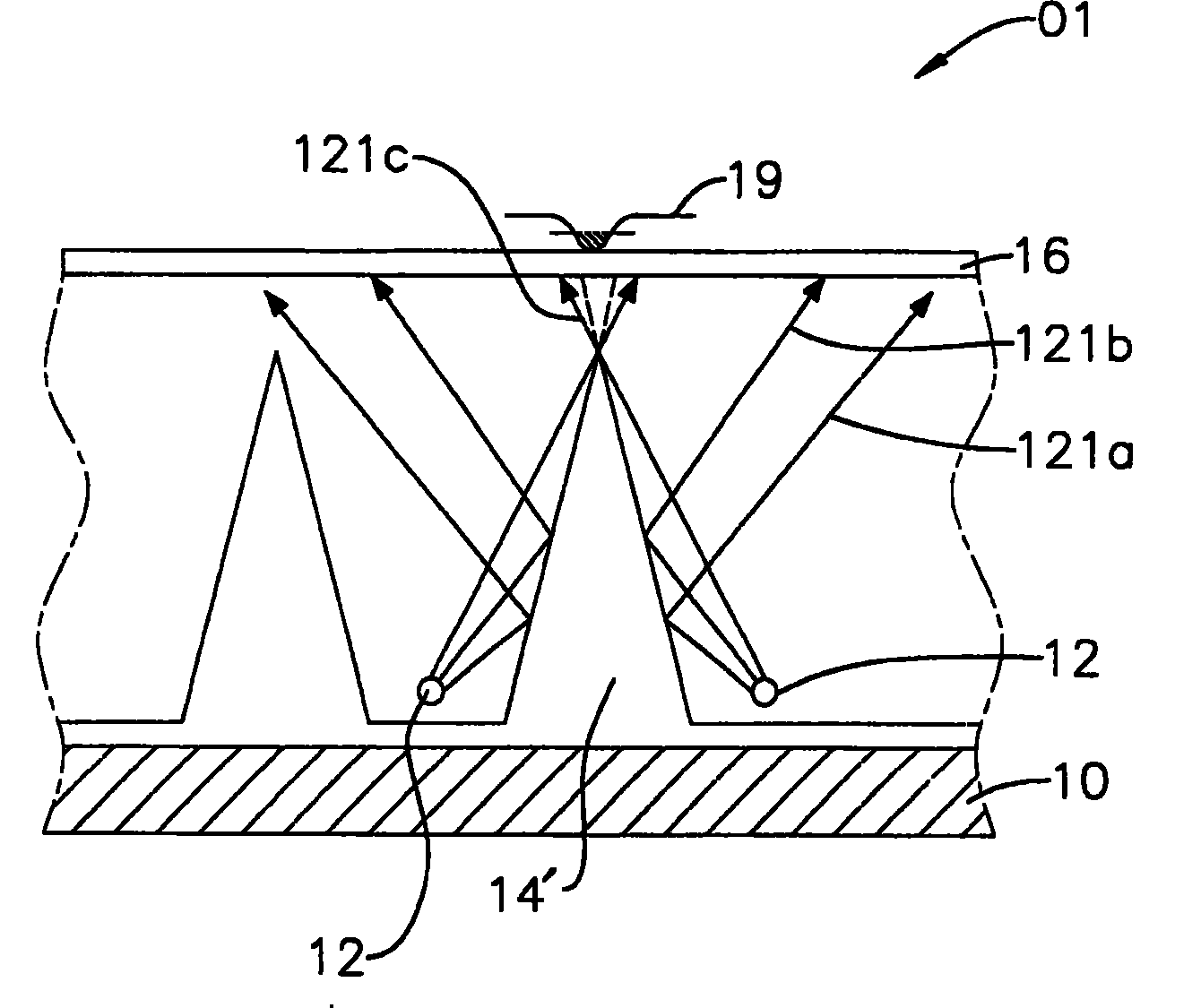

[0055] see Figure 1A-1B . Such as Figure 1A As shown, when the height of a mountain-shaped reflector structure 14 is less than three quarters of the height between the bottom of a light box 10 and a diffuser plate 16, the light sources 12 adjacent to the mountain-shaped reflector structure 14 will all be The light rays 12a, 12b and 12c are emitted, wherein the light ray 12c will directly hit the light overlapping area directly above the reflective sheet structure 14, and the light ray 12b will be reflected at a large angle on the higher surface of the reflective sheet structure 14, so it is incident on the reflective sheet structure 14. The light overlapping area directly above the reflection sheet structure 14 . Therefore, part of the light is concentrated on the top of the mountain-shaped reflector structure 14 , and an unexpected mura 18 is formed on the diffuser 16 , resulting in deterioration of the display quality of the liquid crystal display. Such as Figure 1B As...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com