Method for establishing OPC model

An optical proximity correction and model technology, which is applied to microlithography exposure equipment, photolithography exposure devices, electrical components, etc., can solve the problems of many adjustment steps and long simulation time, and achieve the reduction of adjustment steps and simulation The effect of shortening time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

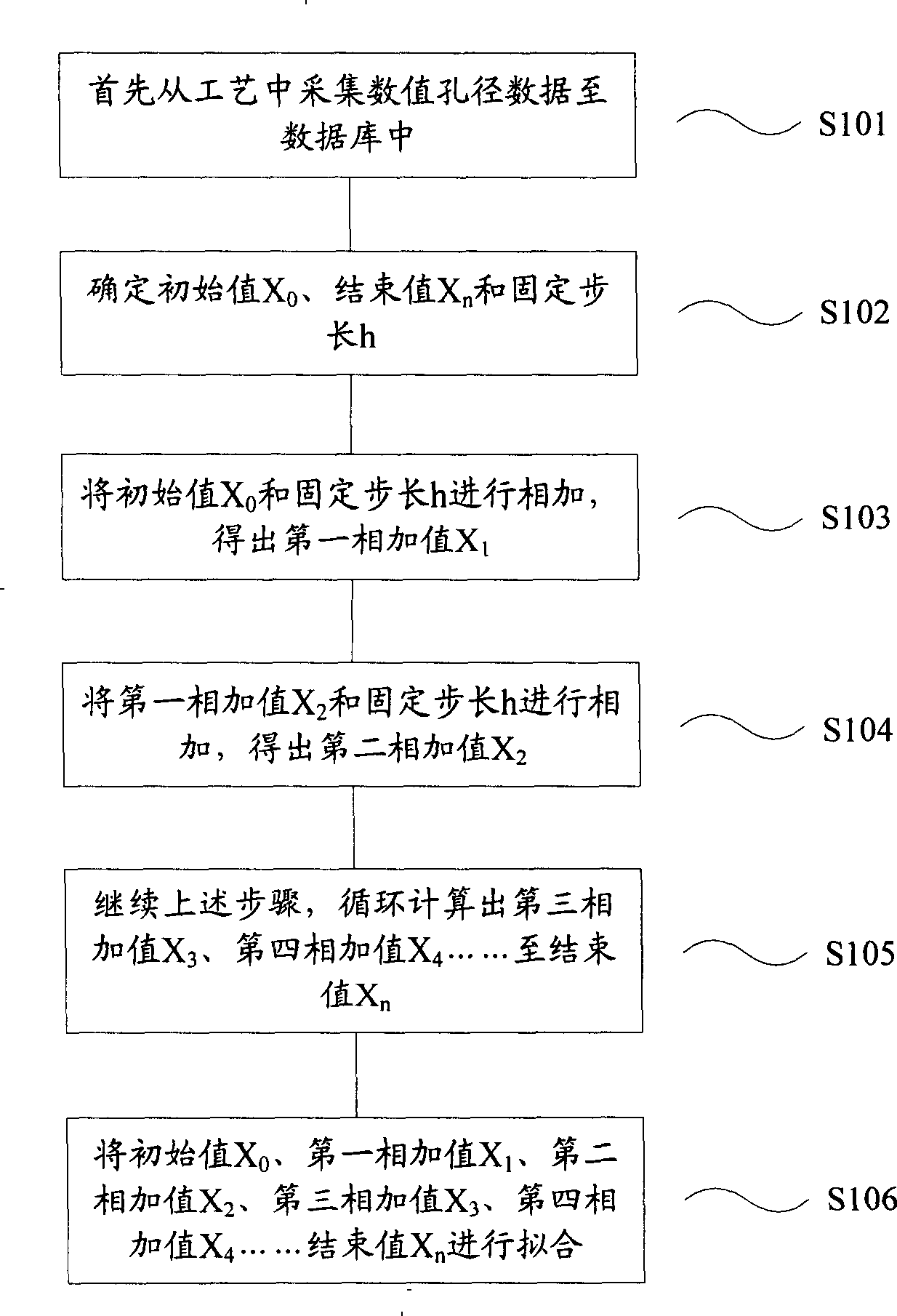

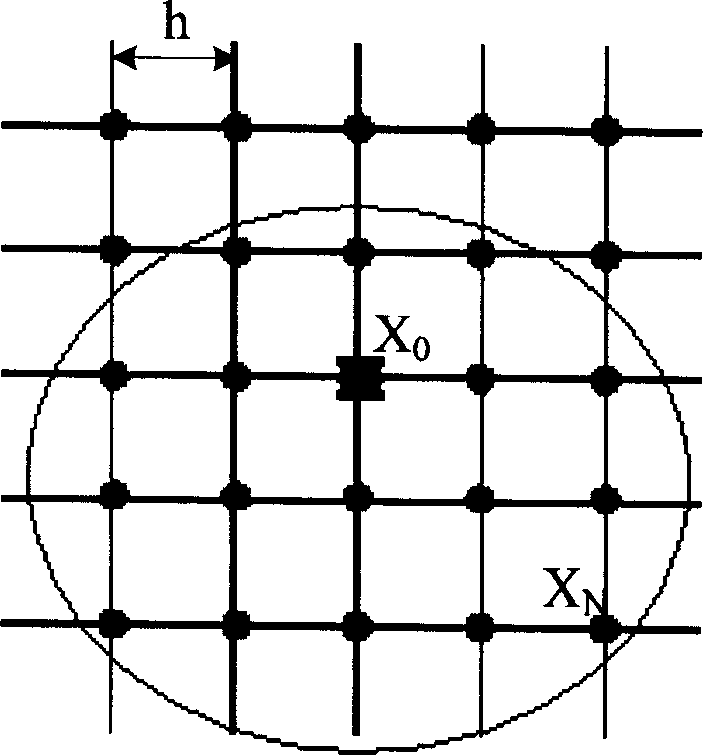

[0020] The linearization of photomask transmission requires the use of many variables, which requires a large amount of computing time to perform the calculation. In the prior art, since the step size is a fixed value, if there is a lot of intermediate data between the initial value and the end value, it will cause the number of steps to be adjusted. Too many and the simulation time becomes longer. Therefore, as the logical feature size decreases, it is necessary to provide a photomask implementation that accurately forms the desired image using the minimum calculation time. The present invention can adjust the number of steps because the step size can be adjusted according to the calculated slope. decrease, the simulation time becomes shorter. In order to make the above objects, features and advantages of the present invention more comprehensible, specific implementations of the present invention will be described in detail below in conjunction with the accompanying drawings....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com