Motor

A shaft tube and magnetic component technology, applied in the field of motors that can effectively improve electromagnetic effects, can solve problems such as poor electromagnetic effects, hot coils, and high-frequency noise, so as to improve the characteristics and overall performance of the motor, avoid hot coils, The effect of avoiding high-frequency noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] A motor according to a preferred embodiment of the present invention will be described below with reference to related drawings.

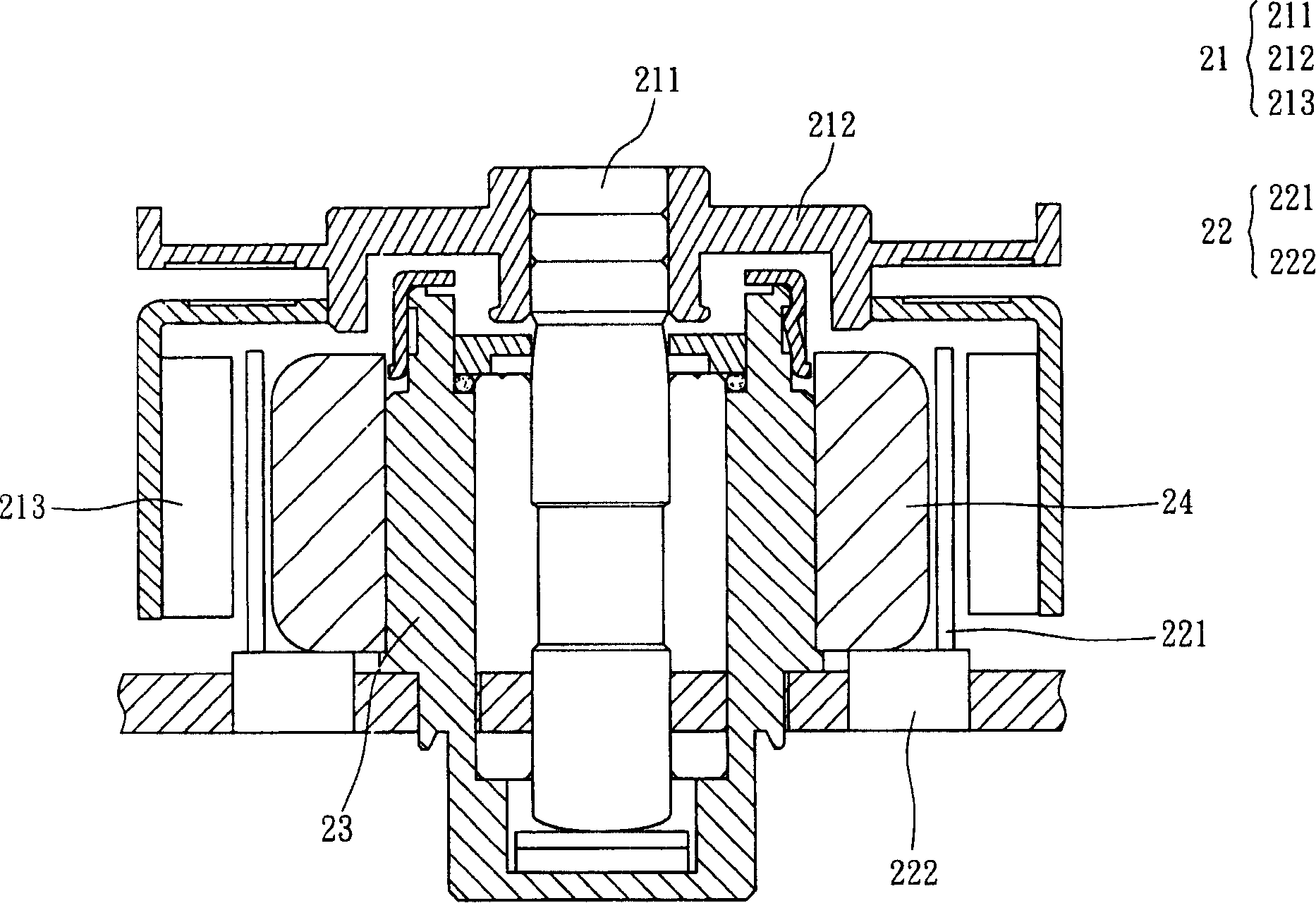

[0019] Please refer to figure 2 As shown, a motor 2 according to a preferred embodiment of the present invention includes a rotor structure 21 , a stator structure 22 and a shaft tube portion 23 , and the motor 2 can be applied to a fan. Wherein, the rotor structure 21 has a rotating shaft 211, a magnetically conductive shell 212 and a magnetic component 213, the rotating shaft 211 is connected with the magnetically conductive shell 212, and is arranged in the shaft tube portion 23, here, the rotating shaft 211 can be embedded or clamped or bonding with the magnetically permeable shell 212 . In addition, the magnetic component 213 is disposed around the inner wall of the magnetically conductive shell 212 , and the magnetic component 213 can be a magnetic ring.

[0020] The stator structure 22 has a coil assembly 221 and a driving circuit ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com