Substrate for light-emitting element packaging, luminescent module, and lighting apparatus

A technology of light-emitting elements and light-emitting modules, which is applied in the direction of lighting devices, components of lighting devices, semiconductor devices of light-emitting elements, etc., which can solve problems such as wiring damage, accelerated wiring insulation material thermal degradation, and large-scale devices. Large-area lighting device, good expandability, and good heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

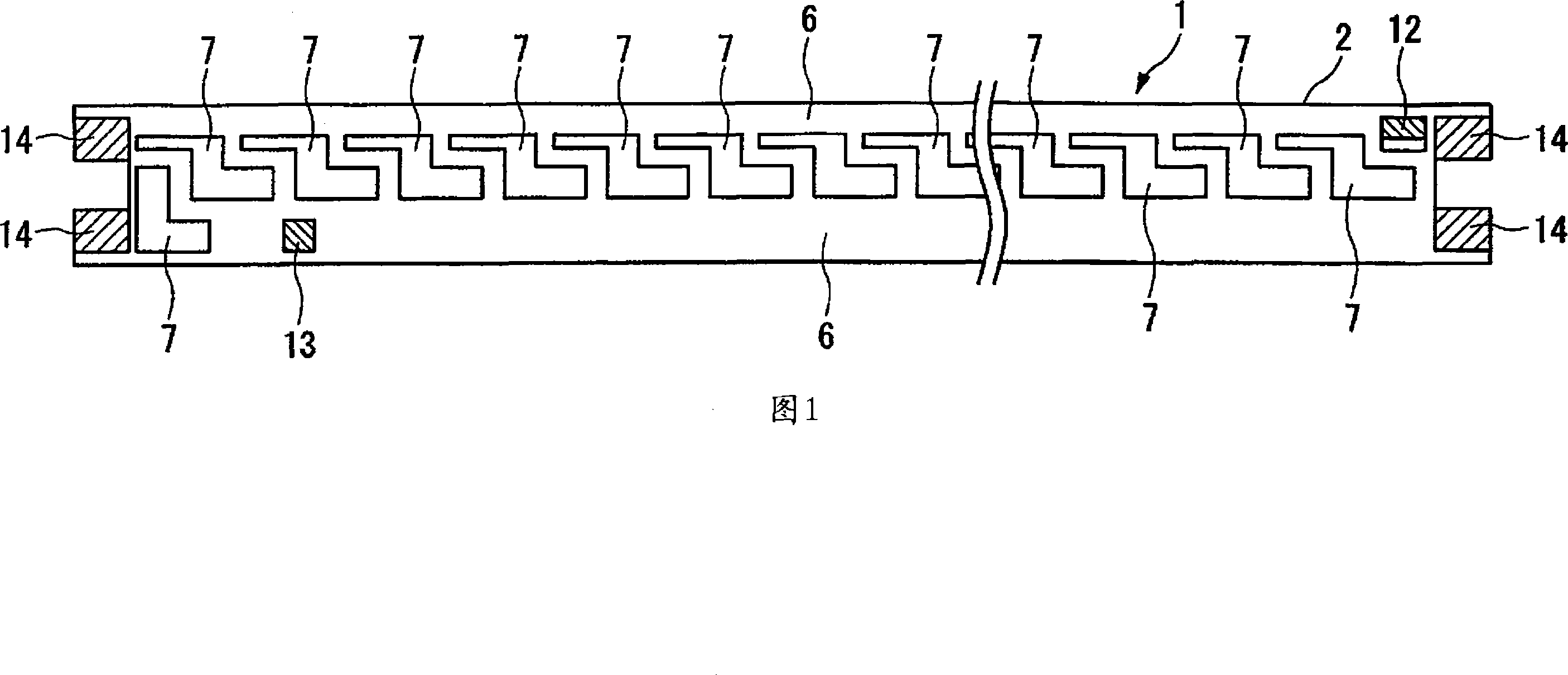

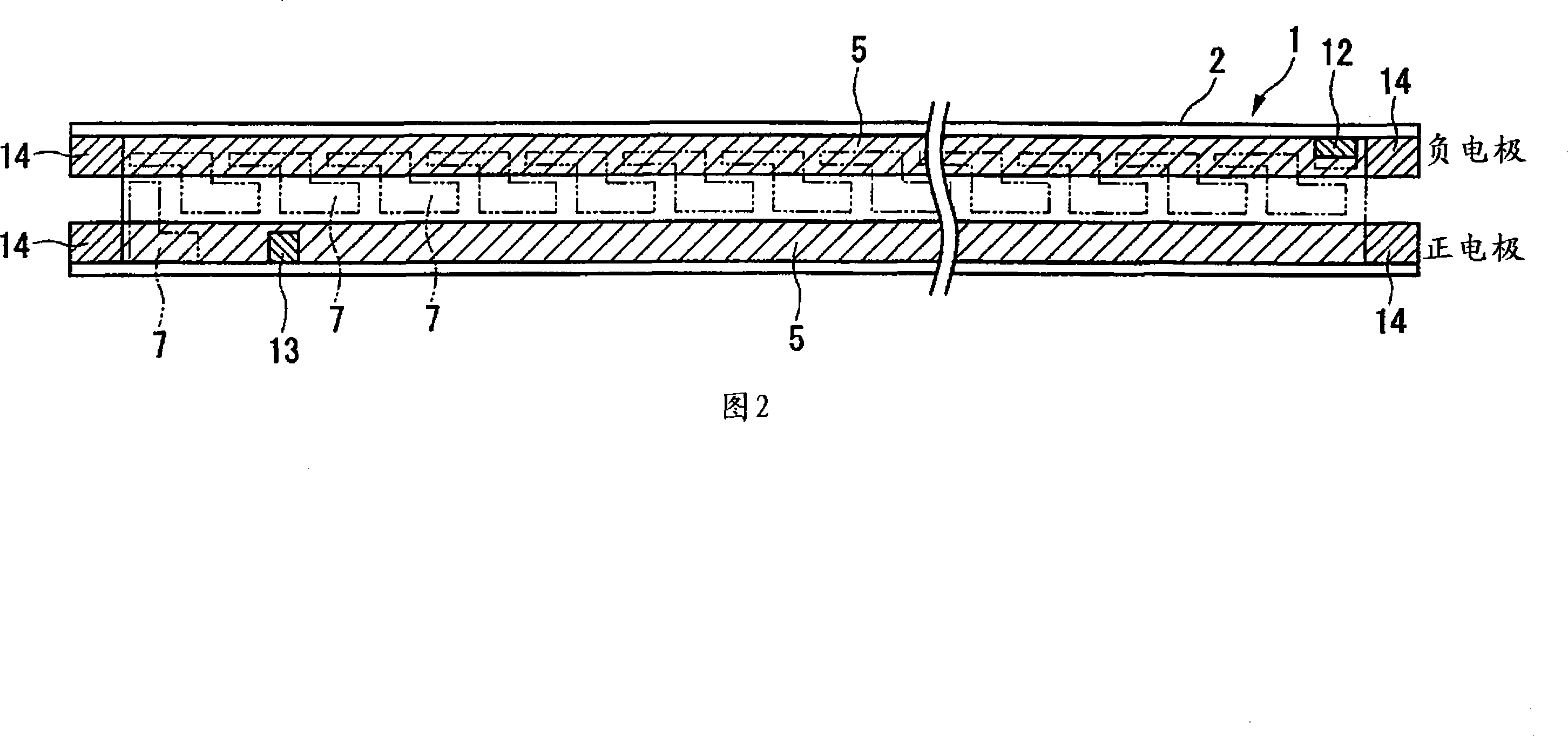

[0026] 1 and 2 are diagrams showing an embodiment of a substrate for mounting a light-emitting element of the present invention. FIG. 1 is a plan view of a substrate for mounting a light-emitting element 1, and FIG. Perspective view of the formation location of layer 5.

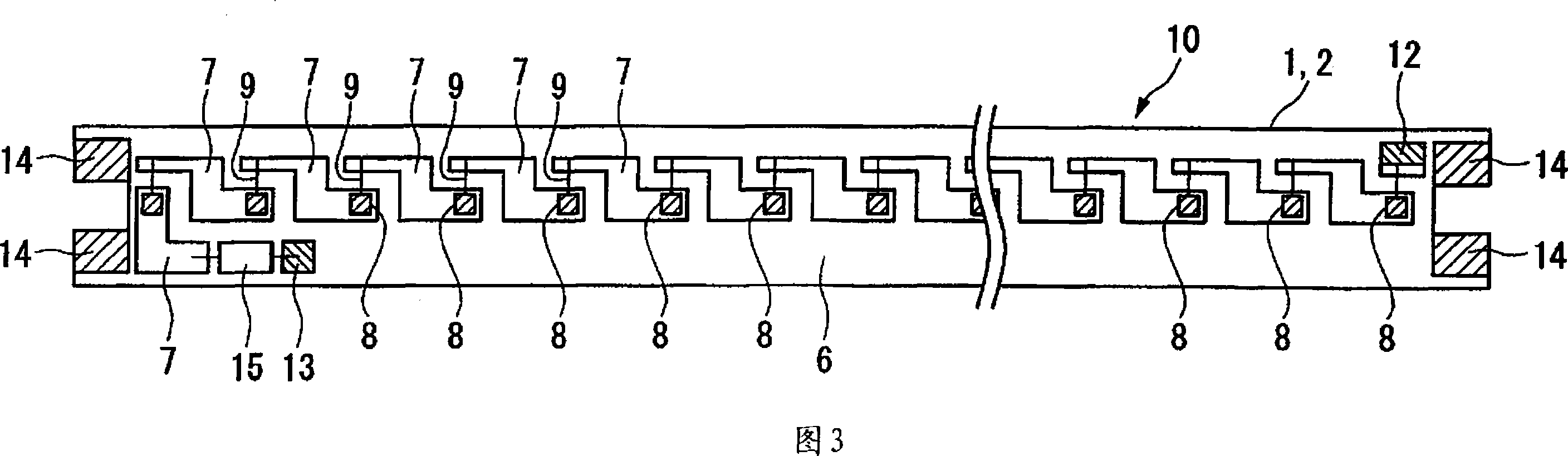

[0027] 3 and 4 are diagrams showing an embodiment of the light emitting module of the present invention, and FIG. 3 is a light emitting module 10 configured by mounting a plurality of light emitting elements 8 on the light emitting element mounting substrate 1 shown in FIG. 1 . In the top view, FIG. 4 is a cross-sectional view of the light emitting module 10 .

[0028] The light-emitting element mounting substrate 1 of the present embodiment is formed by laminating the first conductive layer 5, the second enamel layer 6, and the second conductive layer on the outside of the enamel substrate 2 covered ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com