High pressure sealing apparatus

A technology for high-pressure sealing and sealing components, applied in sealing, engine sealing, packaging, etc., can solve the problems of large number of parts, large manpower, difficult production and assembly of sealing components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

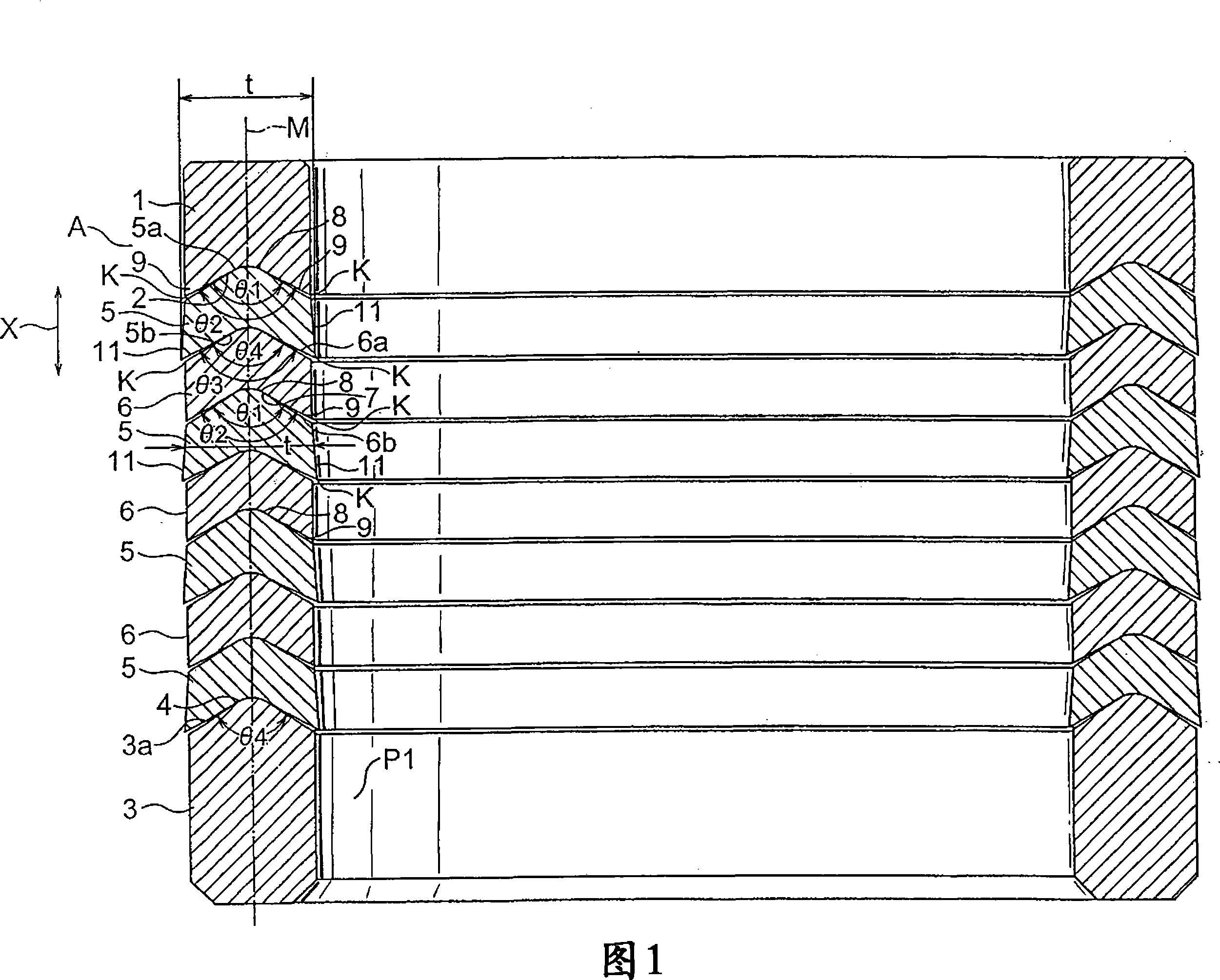

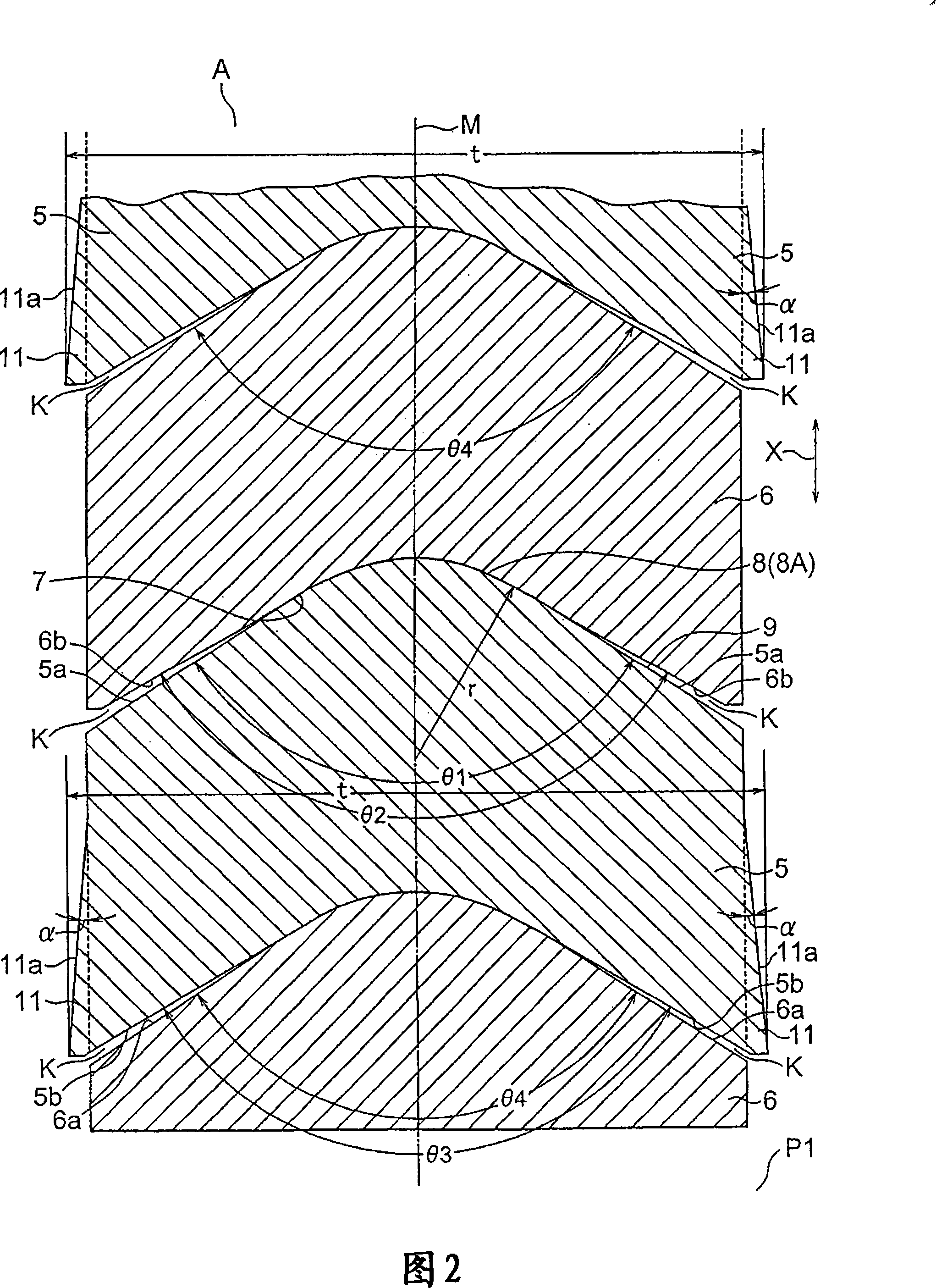

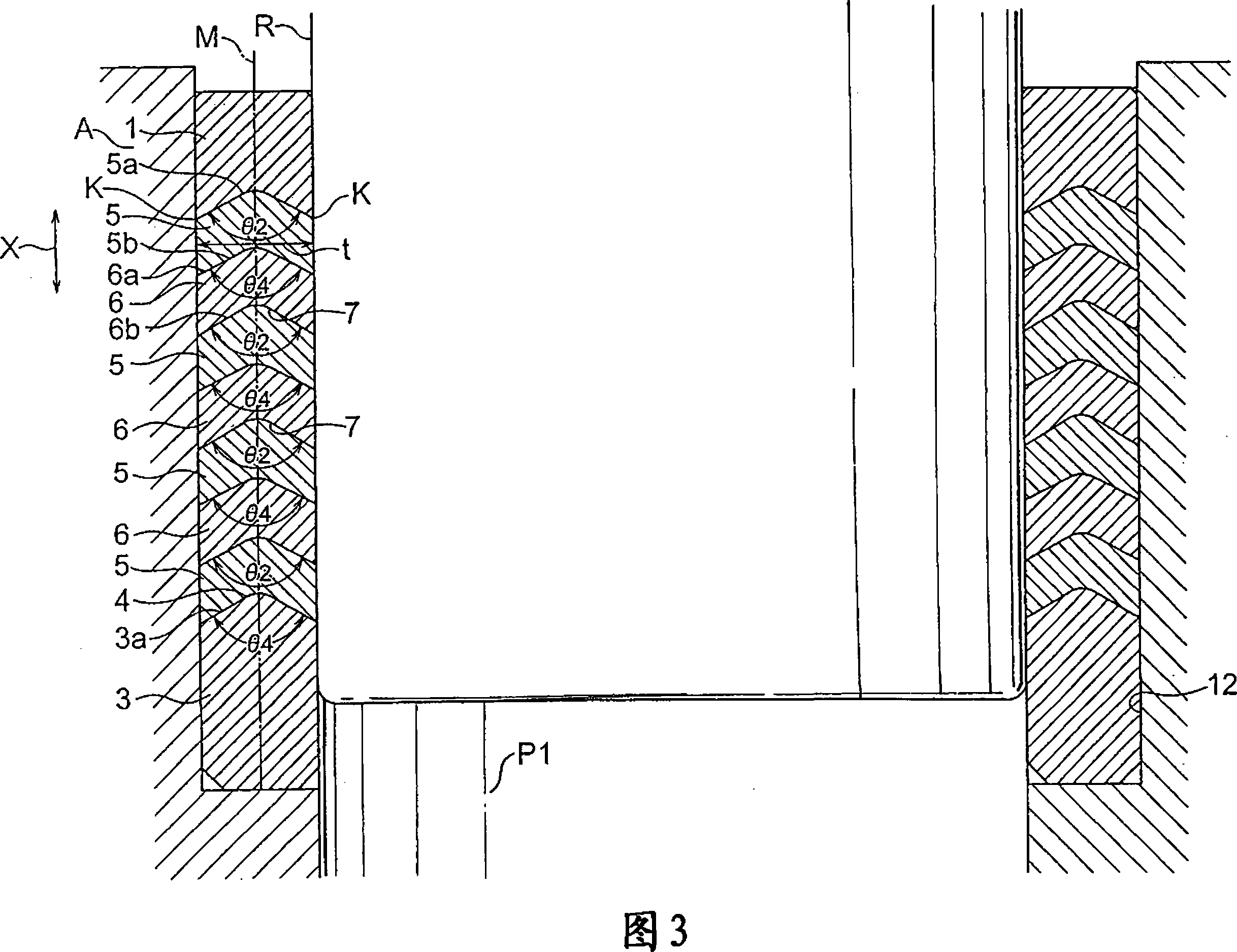

[0051] A first embodiment of a high pressure sealing device according to the present invention will be described with reference to FIGS. 1 to 5 .

[0052] As shown in FIGS. 1 to 5 , the sealing device according to the first embodiment includes:

[0053] a top engaging member 1 having a substantially annular shape in plan view and comprising a seal receiving recess 2 having an inverted V-shaped cross-section at the bottom wall of the top engaging member 1;

[0054] a bottom engagement member 3 having a substantially annular shape in plan view and comprising a seal support wall 4 having an inverted V-shaped cross-section at the top wall of the bottom engagement member 3;

[0055] A plurality of sealing members 5 each having a substantially annular shape in plan view and having an inverted V-shaped cross-section, and the sealing members 5 are interposed between the top joint 1 and the bottom joint 3; and

[0056] A plurality of metal seal support rings 6, each metal seal support...

no. 2 approach

[0079] A second embodiment of the high-pressure sealing device according to the present invention will be described with reference to FIGS. 6 to 9 .

[0080] In the second embodiment, deformation allows the gap K to be formed at the bottom wall 5 b of the sealing member 5 . In the first embodiment, when the pressing force is released, the deformation allowing gap K is formed at both the top wall 5 a and the bottom wall 5 b of the sealing member 5 . In the second embodiment, the inclination angle θ1 formed on the top wall 5a of the sealing member 5 is substantially the same as the inclination angle θ'2 formed on the bottom wall of the top joint member 1 and the inclination angle θ'2 formed on the seal support ring 6. The inclination angle θ'2 of the seal receiving portion 7 on the bottom wall 6b is equal. In addition, the inclination angle θ3 formed on the bottom wall 5b of the seal member 5 is larger than the inclination angle θ4 of the top wall 6a of the seal support ring 6 ...

no. 3 approach

[0084] 10 and 13 show a third embodiment of the sealing device according to the invention.

[0085] In the third embodiment, unlike the first embodiment, a deformation-allowing gap K is formed on the top wall 5 a of the sealing member 5 . That is, in the third embodiment, the inclination angle θ1 formed on the top wall 5 a of the seal member 5 is smaller than the inclination angle θ2 of the seal receiving recess 2 formed on the bottom wall of the top joint 1 , and smaller than the inclination angle θ2 formed on the seal support ring 6 . The inclination angle θ2 of the seal receiving portion 7 on the bottom wall 6b of the . In addition, the inclination angle θ3 formed on the bottom wall 5b of the sealing member 5 is substantially equal to the inclination angle θ4 of the top wall 6a of the seal support ring 6 and the inclination angle θ4 of the top wall of the bottom engaging member 3 . The deformation formed at the top wall 5 a of the seal member 5 allows the gap K to widen as...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com