Turbulent-current long-flame top burning type hot blast stove combustor

A burner and top-burning technology, which is applied to gas fuel burners, burners, combustion methods, etc., can solve the problem of uniform distribution of high-temperature smoke flow, achieve uniform air distribution, reasonable design, and prolong service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

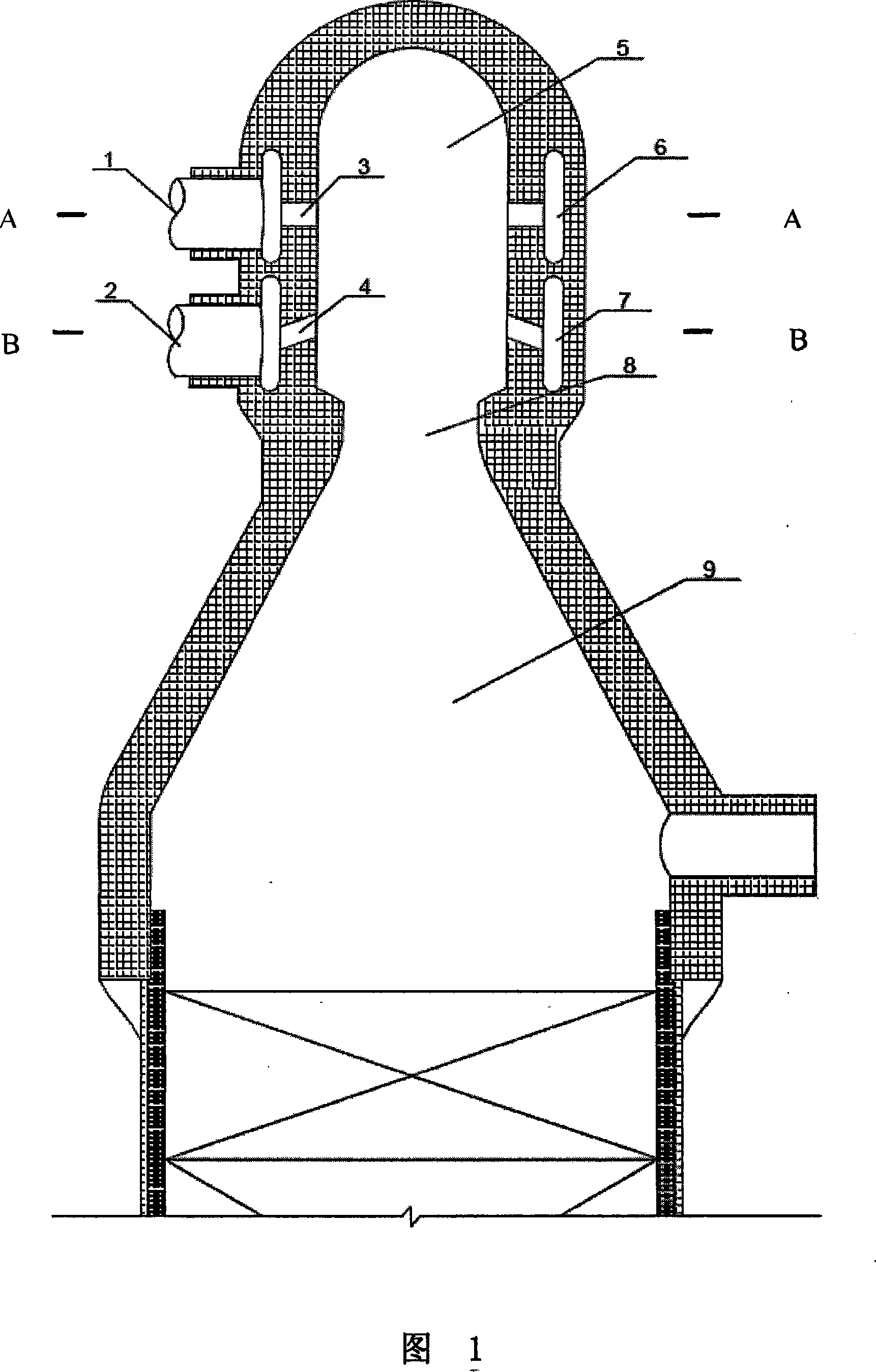

[0017] A turbulent long-flame top-fired hot blast stove burner of the present invention will be described in detail below with reference to the accompanying drawings.

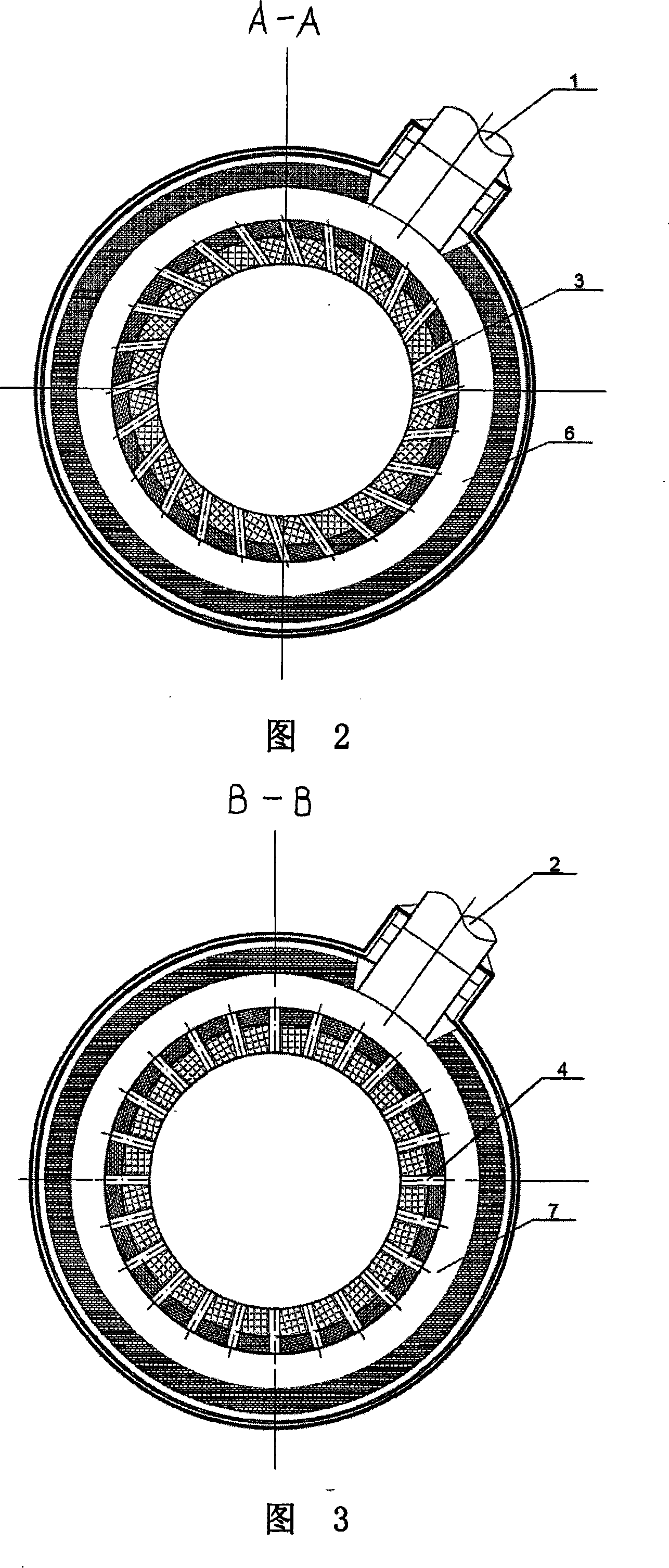

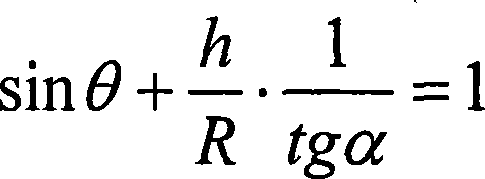

[0018] A turbulent long-flame top-burning hot blast stove burner of the present invention, the burner made of refractory material is arranged on the upper part of the combustion chamber, and a narrow combustion chamber is arranged between the premixing chamber 5 and the combustion chamber 9 of the burner. Part 8, 12-24 independent gas nozzles 3 and 12-24 independent air nozzles 4 are distributed on the side wall of the premixing chamber 5. As shown in Figure 2, the gas nozzle 3 has a certain rotation angle in the radial direction of the burner, and the number of the gas nozzle 3 is determined by the diameter of the hot blast stove; The number of nozzles and air nozzles is the same, corresponding up and down.

[0019] The axial inclination angle range of the air nozzle is 0-30° (excluding zero inclination angle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com