Walking carriage and system thereof

A technology of moving trolleys and variable quantities, which is applied in the direction of control/regulation systems, railway car body parts, vehicle control route devices, etc. It can solve problems such as difficult feedback control and inability to continuously detect slippage, so as to eliminate slippage and shorten The effect of moving time and increasing the number of rotations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

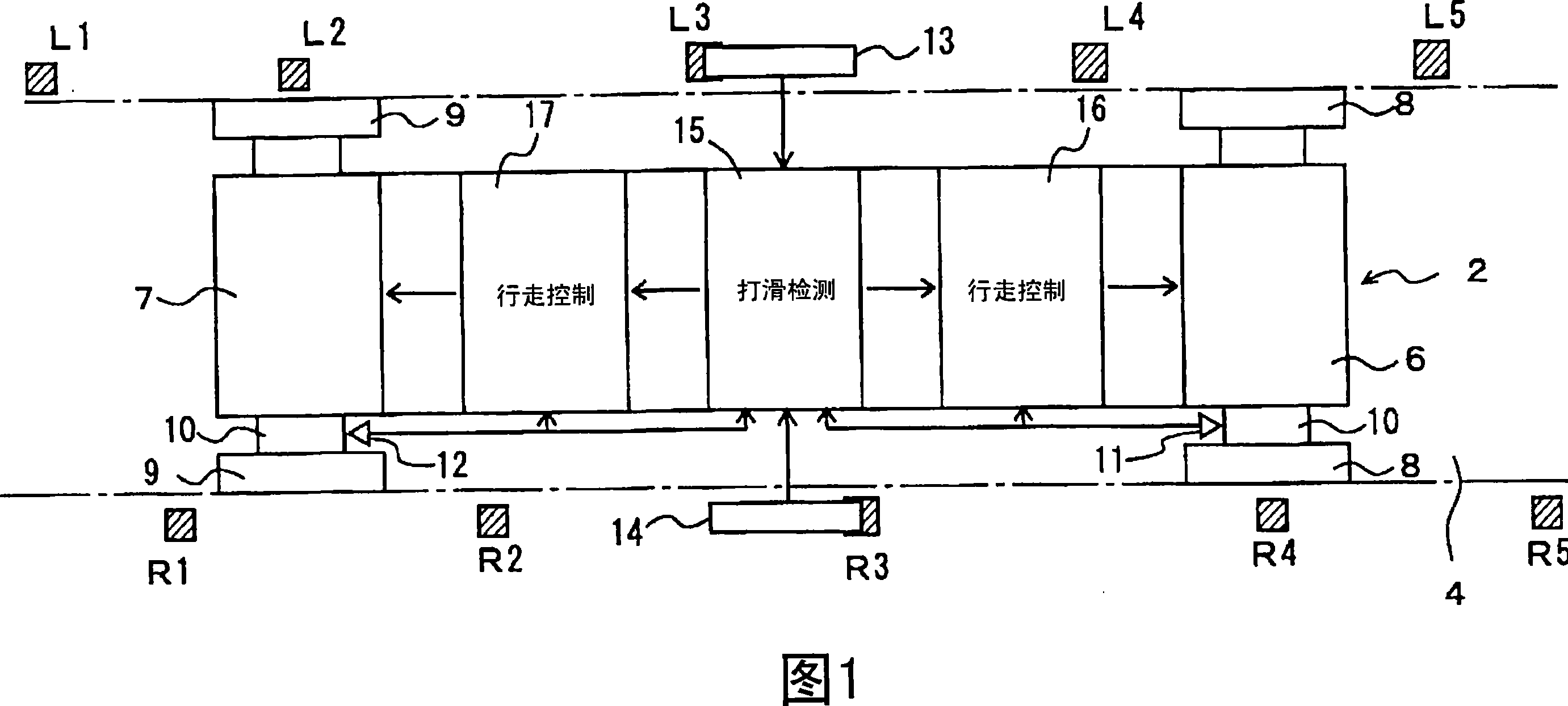

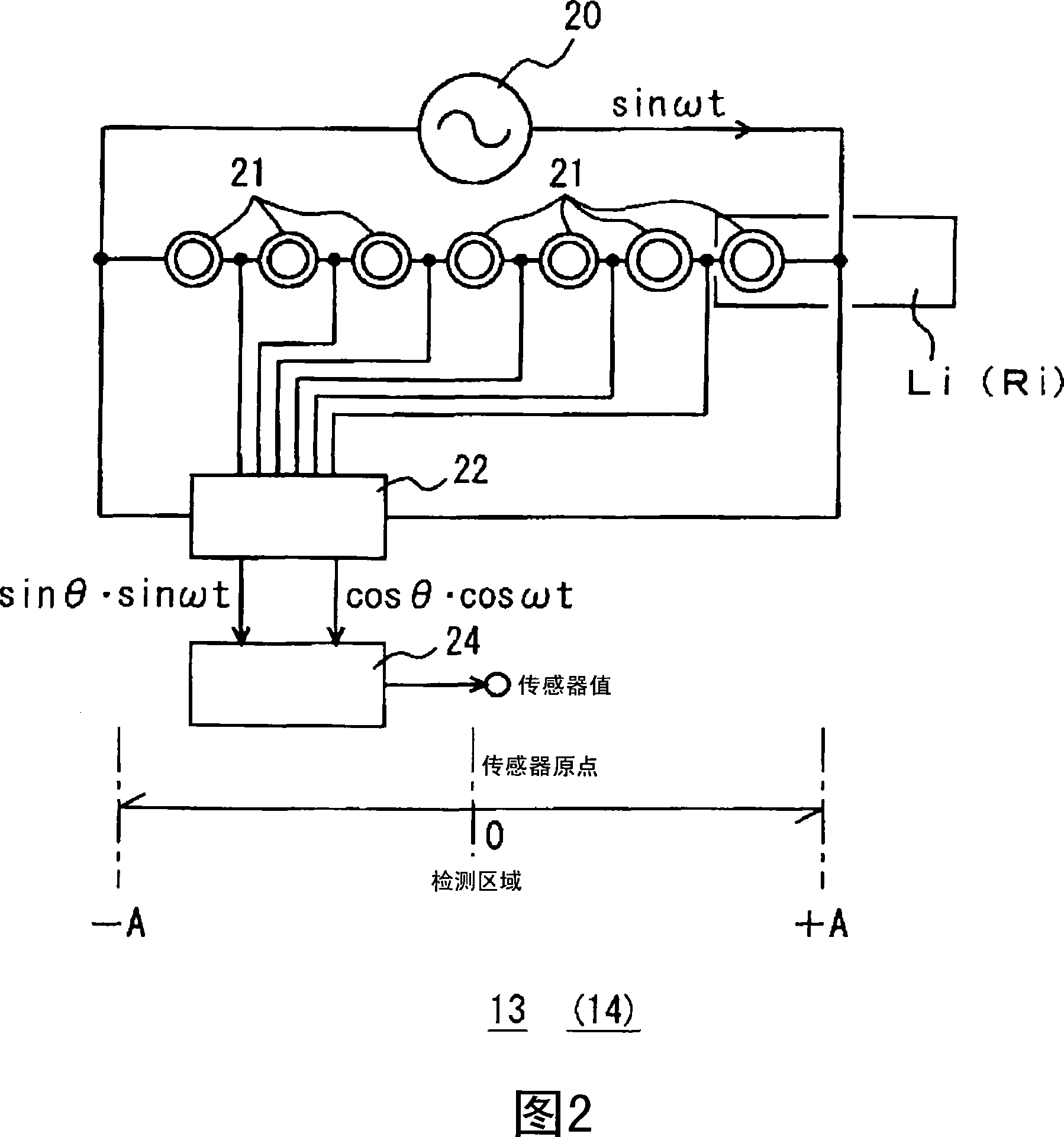

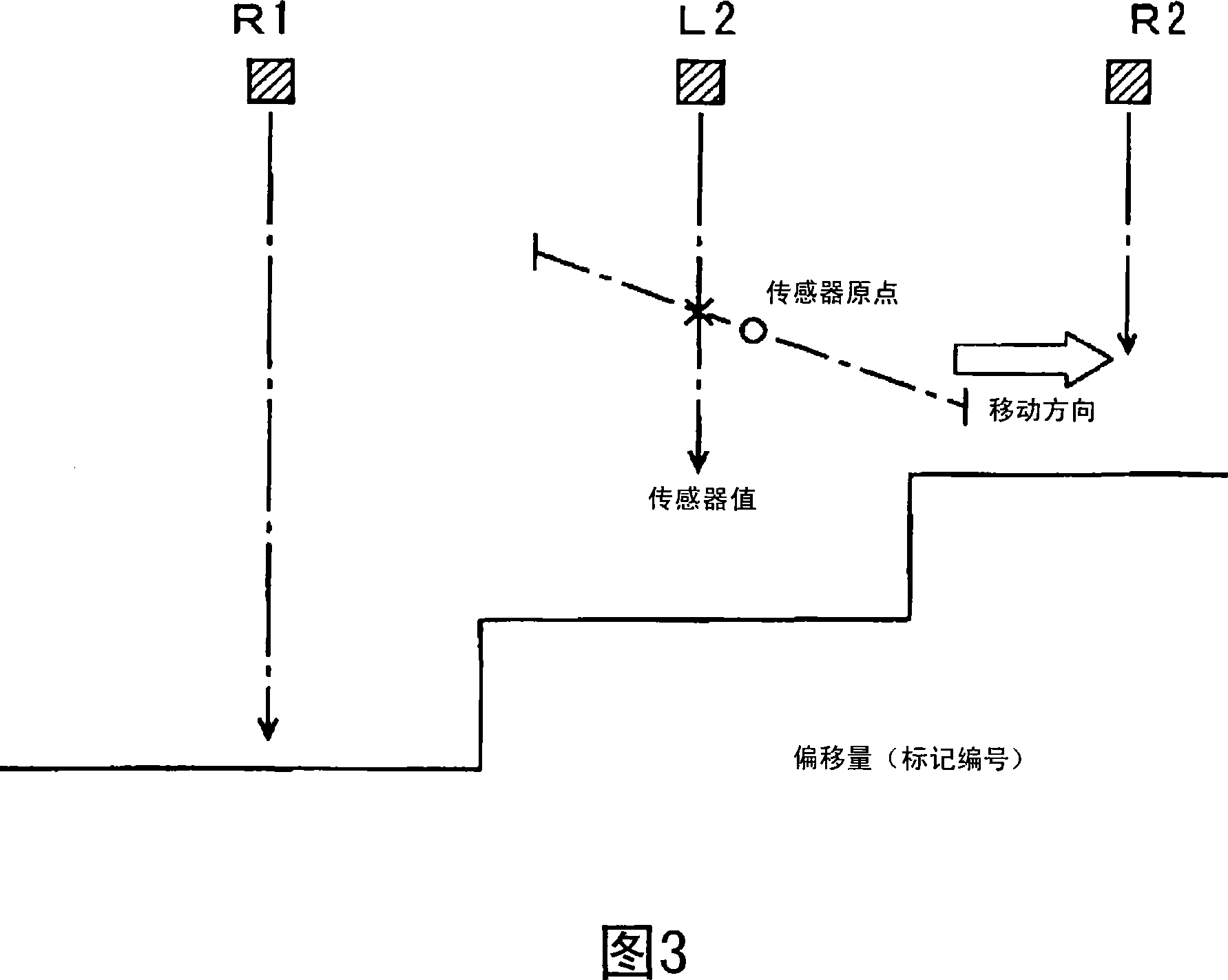

[0020] 1 to 5 show the traveling trolley system of the embodiment. 2 in the figure is a walking trolley, which can be a rail trolley or a trackless trolley, such as a stacking crane or a rail trolley, an unmanned vehicle, an overhead crane, etc. In addition, the walking vehicle also includes a vehicle performing motion other than horizontal walking. The traveling vehicle 2 generates a traveling speed curve from a starting point to a destination by a traveling speed curve generating unit not shown in the figure, and travels according to the speed curve. 4 is a walking path, and the walking trolley 2 rotates or reciprocates along the walking path 4. The walking trolley 2 is equipped with, for example, front and rear traveling motors 6, 7, which drive the traveling wheels 8, 9 respectively. 10 is a drive shaft, connected to the traveling motors 6, 7 And traveling wheels 8,9, encoder 11,12 is arranged along drive shaft 10, detects its rotation amount that is the driving amount of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com