Sewage water treatment system

A sewage treatment system and sewage technology, applied in water/sewage multi-stage treatment, adsorption water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of low service life, expensive equipment, high nitrogen and phosphorus content, etc. , to achieve the effect of convenient operation and management, enhanced removal effect and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

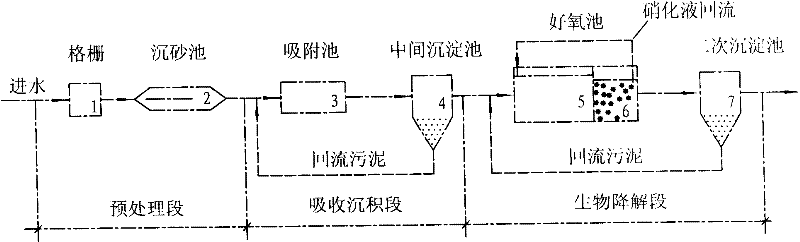

[0024] figure 1 It is a flowchart structure diagram of a sewage treatment system determined by the present invention. As shown in the figure, the water treatment method is divided into three sections: pretreatment section, adsorption deposition section, and biodegradation section.

[0025] The pretreatment section includes grid 1 and grit chamber 2. The sewage first passes through the grid 1 to remove coarse suspended solids and sundries, and then enters the grit chamber 2, where the inorganic particles contained in the sewage are removed through physical settlement to protect subsequent equipment. Of course, in this pretreatment section, other methods can also be used to initially remove coarse suspended solids and impurities in the water, such as filtration or air flotation, which can also achieve the same effect of removing impurities and realize t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com