Method and sensor for detecting randomly performance of engine lubricating oil

A lubricating oil and engine technology, which is applied in the field of lubricating oil performance testing devices, can solve the problems of affecting the service life of the engine and lubricating oil entering more water, and achieve the effects of avoiding cumbersome inspection work, low cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

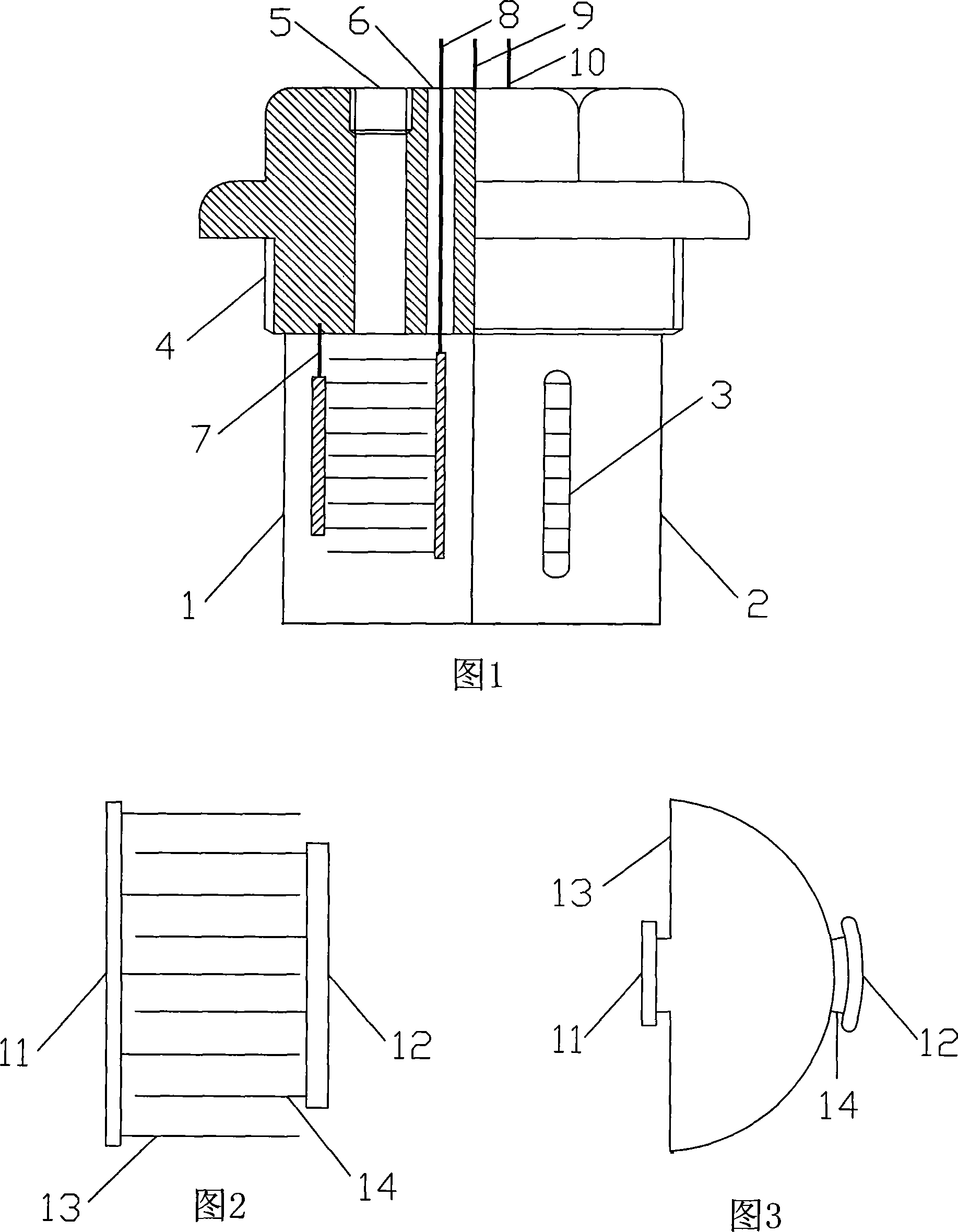

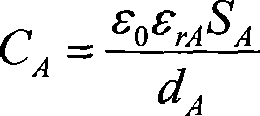

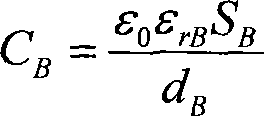

[0032] Referring to Fig. 2 and Fig. 3, the capacitor has a pair of pole plates, that is, the M pole plate 13 and the N pole plate 14, wherein the M pole plate 13 is installed on the M base 11 correspondingly, and the N pole plate 14 is correspondingly installed on the N base Seat 12. The reference capacitor A and the sampling capacitor B are set to be exactly the same in shape and plate parameters.

[0033] Referring to Fig. 1, on the same threaded base 4, an airtight container 1 and a through-hole container 2 with an oil hole 3 are arranged side by side, the reference capacitor A is arranged in the airtight container 1, and the sampling capacitor B is arranged in the through-hole container 2 Among them, each of the two capacitors has an electrode connected to the sensor shell, one electrode of the reference capacitor A shown in Figure 1 is connected to the sensor shell through a wire 7, and the other electrode leads to the outside of the sensor. This structural form The sens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com