Control device for boiler equipment and gas concentration concluding apparatus

A boiler equipment and control device technology, applied in the direction of combustion control, adaptive control, general control system, etc., can solve the problem that the optimal solution is not disclosed or implied, and achieve the effect of improving the accuracy of inference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

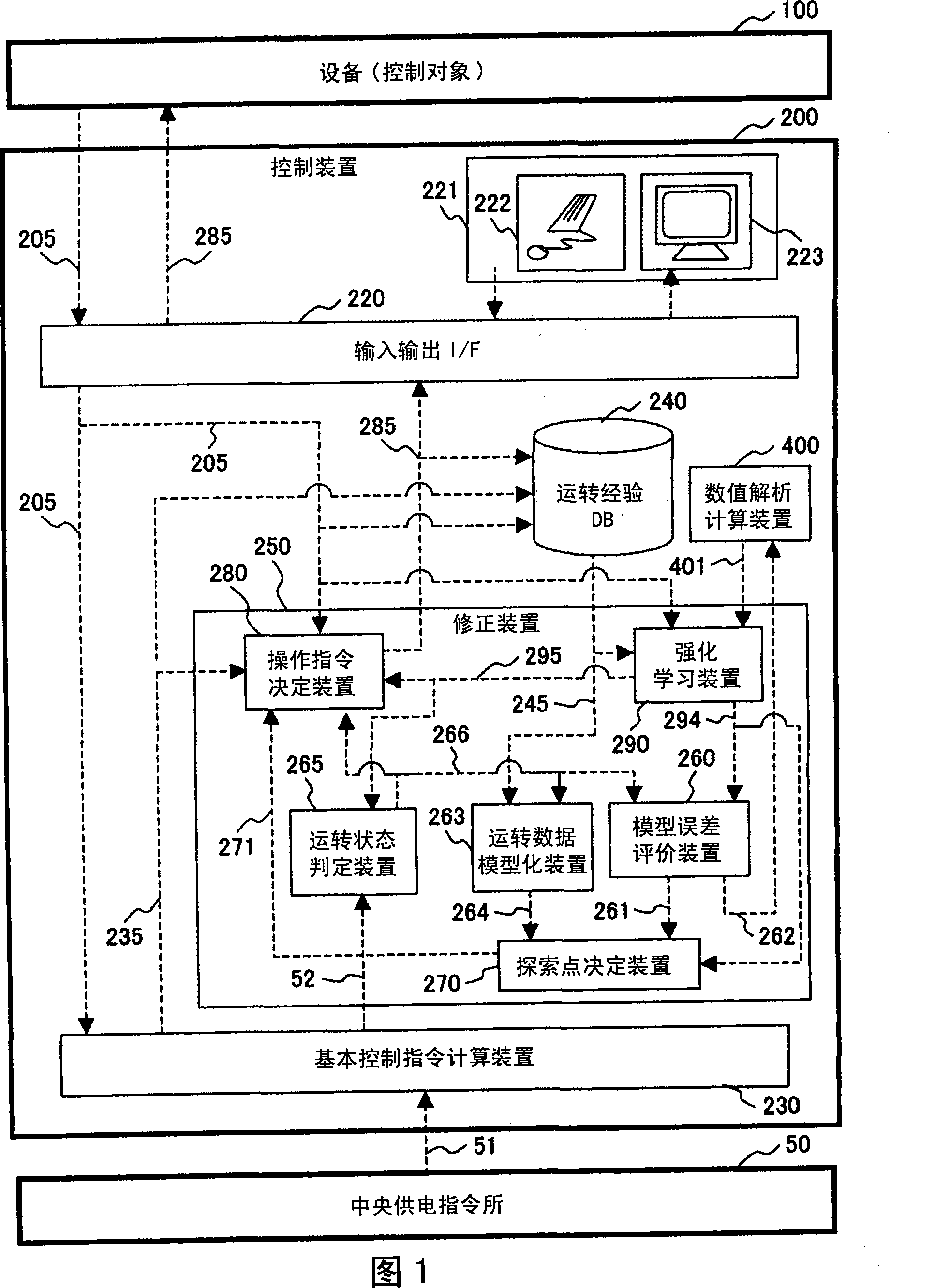

[0052] Fig. 1 is a control block diagram showing a control device of a boiler plant according to an embodiment of the present invention;

[0053] In FIG. 1, for example, the control device 200 of the equipment 100 that takes the boiler equipment of thermal power generation equipment as the control object receives measurement information 205 of various process values from the equipment 100 of the control object, and uses these measurement information 205 to control Preprogrammed calculations are performed within 200 , and an operation command signal (control signal) 285 is sent to the device 100 .

[0054] The device 100 is controlled by operating an operating device included in the device 100 according to an operation command signal 285 received from the control device 200, for example, an actuator such as the opening degree of a valve or the opening degree of a shock absorber that adjusts the flow rate of a fluid flowing through the device. The state of the device 100 .

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com