Numerical control electrical machine

A numerically controlled motor and magnetoelectric induction technology, applied in the direction of non-electric variable control, position/direction control, control/adjustment system, etc., can solve the problems of inaccurate positioning, limited limit range, easy wear of parts, etc., and achieve mechanical connection The effect of less, prolonging the service life, and less power loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

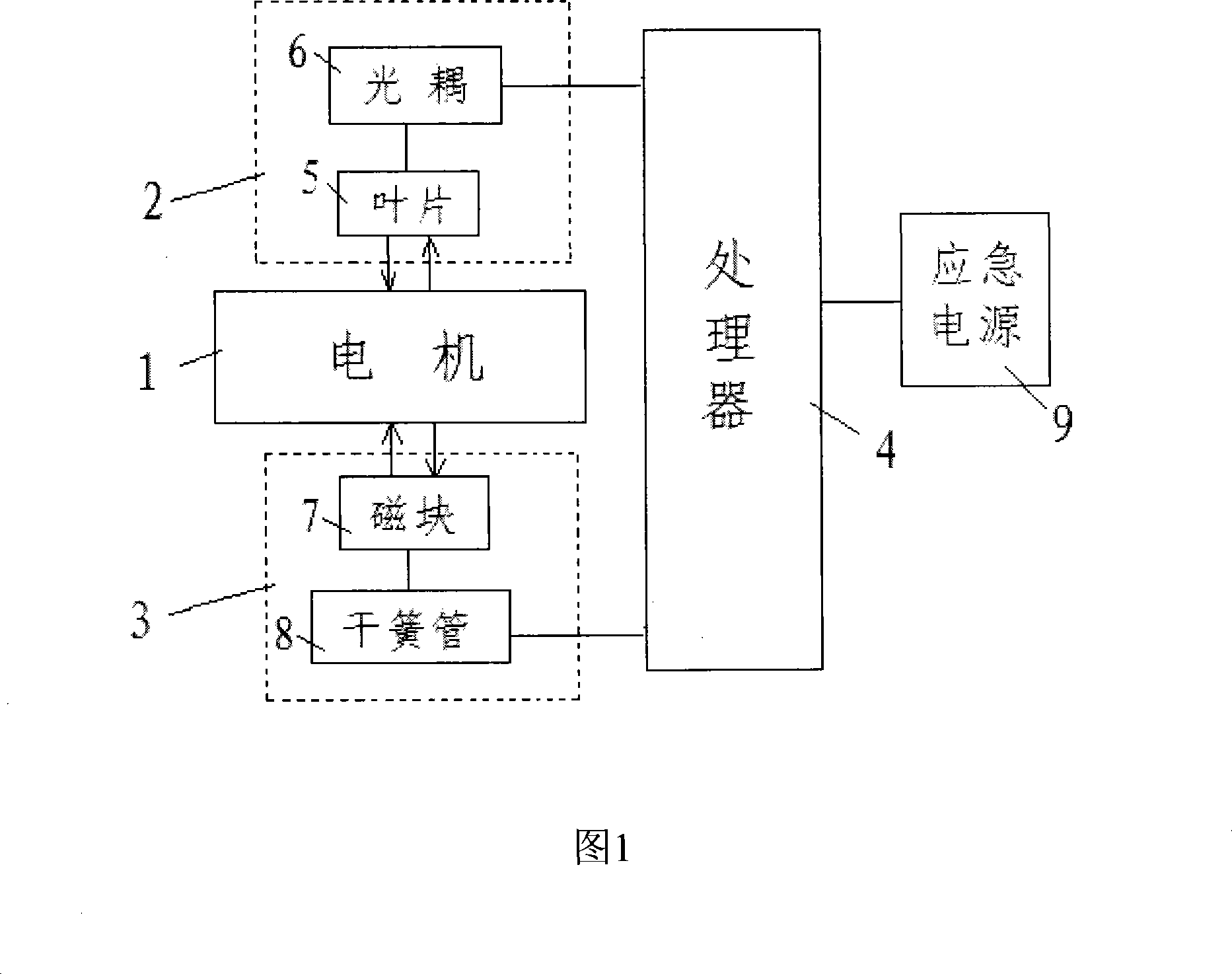

[0008] As shown in Figure 1, it comprises the photoelectric induction module 2 that is connected with motor 1, magnetoelectric induction module 3 and processor (MCU) 4, and photoelectric induction module 2 is provided with blade 5 and optocoupler 6, and magnetoelectric induction module 3 is provided with Magnetic block 7 and dry reed switch 8. The rotating shaft of the motor 1 drives the magnetic block 7 and the blade 5 to rotate, and the control part collects the motion information of the motor 1 through the reed switch 8 and the optocoupler 6; The magnetic block 7 of the module 3 is driven, and it turns over the sensing range of the reed switch 8 to wake up the processor 4 to work; the optocoupler 6 of the photoelectric sensor module 3 counts the rotation of the leaf 5, thereby knowing the rotation of the motor 1.

[0009] An emergency power supply 9 can be connected to the processor 4, and when the motor 1 has no external power supply, the emergency power supply 9 supplies ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com