Permanent magnetism contactor operation mechanism

An operating mechanism and contactor technology, applied in the direction of electromagnetic relays, electromagnetic relay details, relays, etc., can solve problems such as inability to automatically break

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

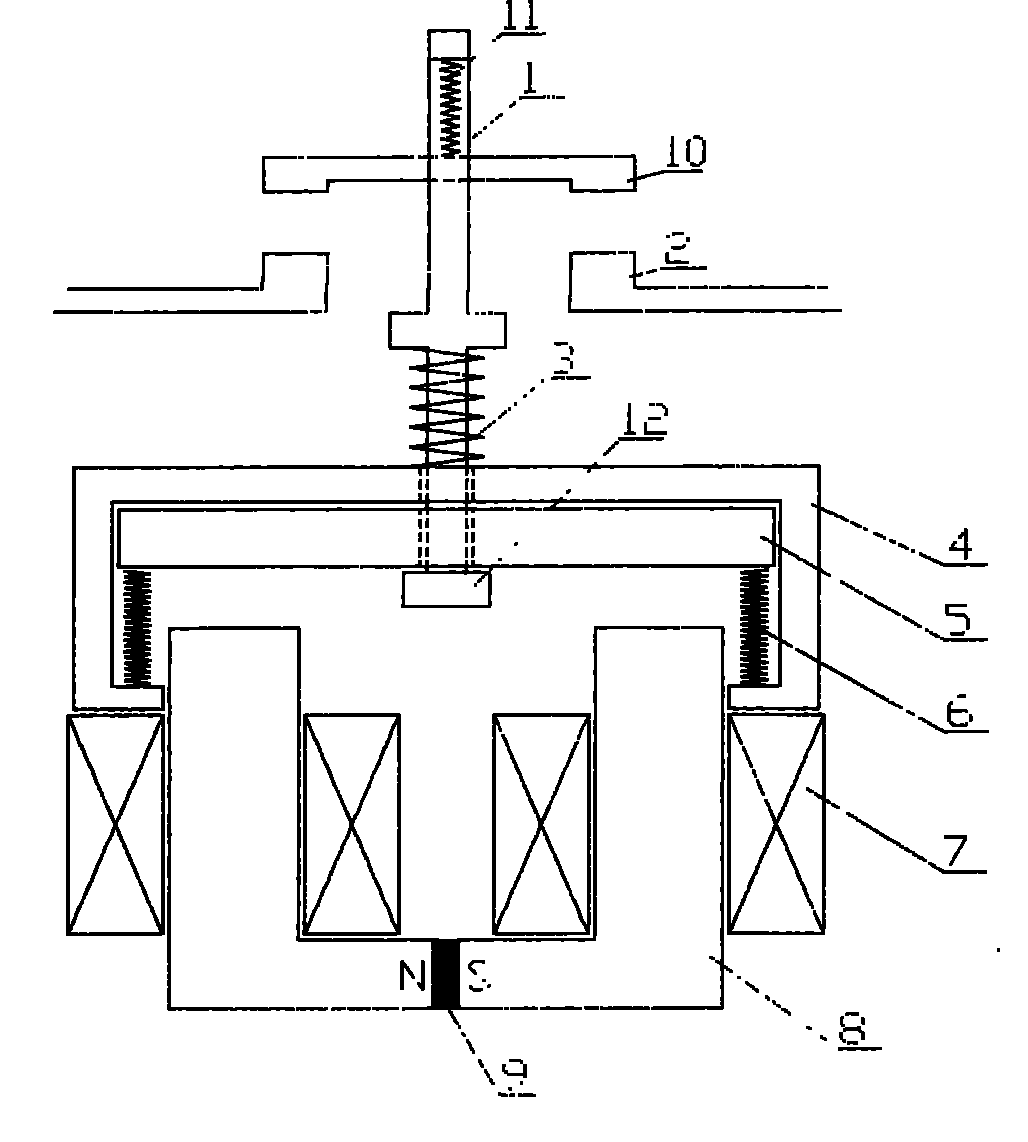

[0024] The U-shaped structure of the permanent magnet contactor operating mechanism of the present invention, as shown in (Fig. 1), mainly consists of a contact drive shaft 1, a static contact 2, a first spring 3, a molded case support 4, and a moving iron core 5 , The second spring 6, the coil 7, the static iron core 8, the permanent magnet 9, the moving contact 10, the contact spring 11, and the support 12 are composed. Its structural features are: a moving iron core 5 is provided at the upper end of the molded case bracket 4, the upper end of the second spring 6 is pushed against the lower part of the moving iron core 5, and the lower end of the second spring 6 is pushed against the lower part of the plastic case bracket 4. The second spring 6 provides the reaction force of the moving iron core 5; the static iron core 8 has two parts, a permanent magnet 9 is arranged between the two parts of the static iron core 8, and a coil 7 is respectively arranged on the two parts of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com