Champignon stone as well as manufacturing method thereof and smouldering furnace used therein

A manufacturing method and a technology of a smoldering furnace, which are applied in the directions of essential oils/fragrance, fat generation, gasification substances, etc., can solve the problems of artificial solid fragrance being difficult to last, and achieve the effects of simple structure, convenient use and fragrant smell.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

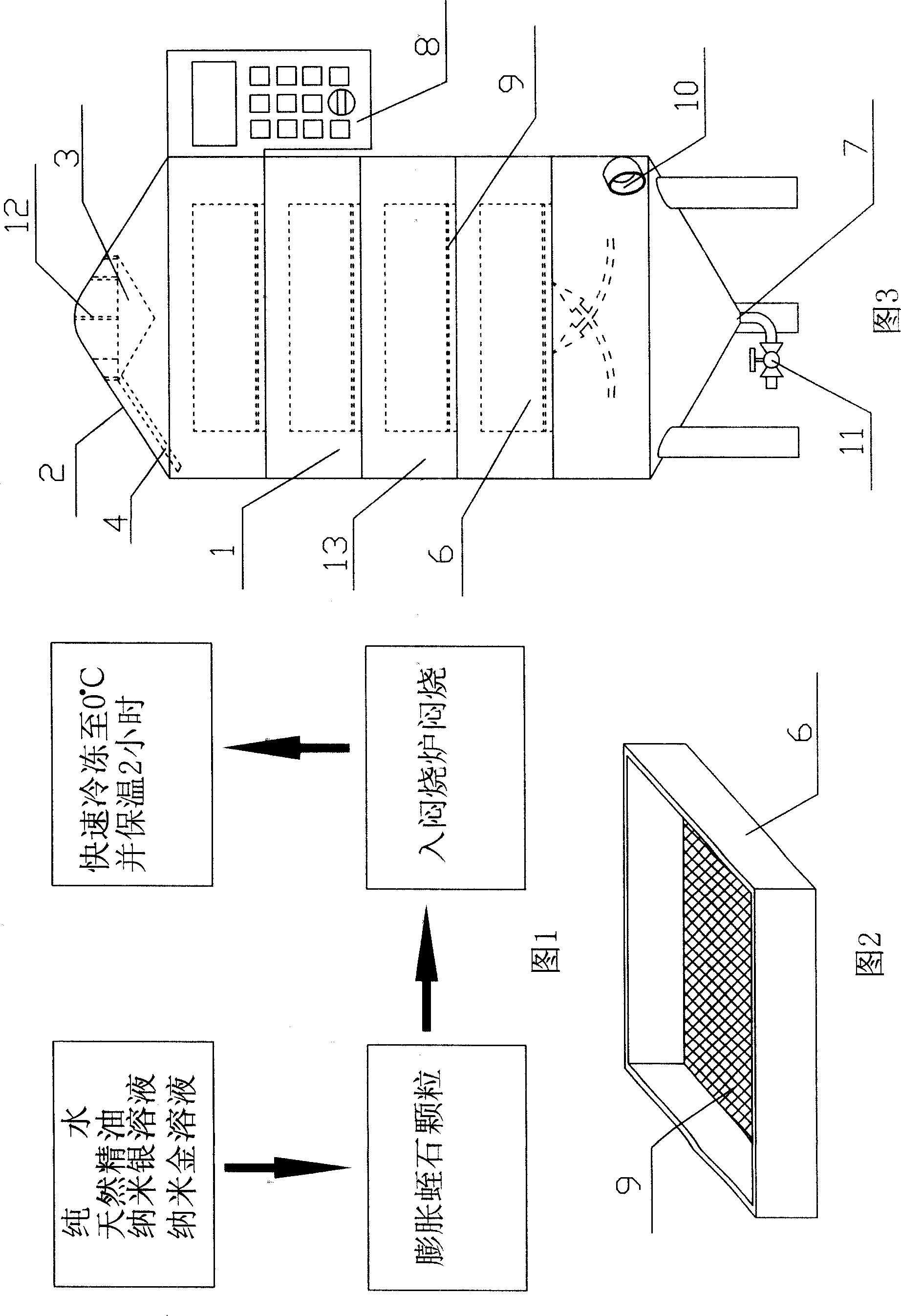

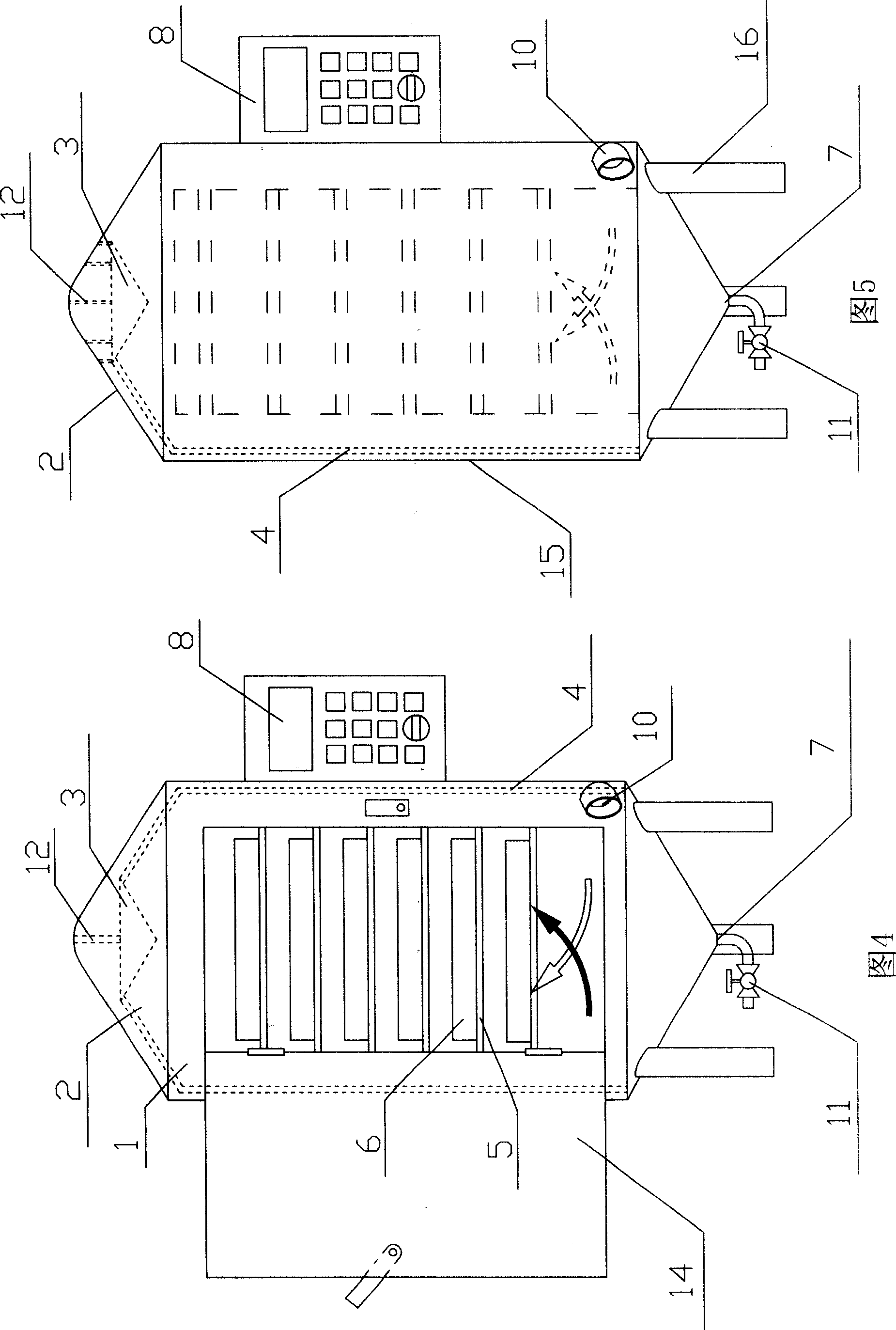

[0028] Embodiment one: as shown in Figure 1, the manufacture method of aromatherapy stone of the present invention, comprises the following steps:

[0029] 1. Get 1000 grams of expanded vermiculite particles, add 1000 grams of pure water, 5 grams of natural essential oil, 0.5 mg of nano-gold aqueous solution and 0.5 mg of nano-silver aqueous solution, wherein the nano-gold aqueous solution, the The weight concentration of said nano-silver aqueous solution is 100PPM;

[0030] ②. Put the above-mentioned expanded vermiculite particles adsorbed with pure water, natural essential oil, nano-gold aqueous solution, and nano-silver aqueous solution into a smoldering pan, then put them into a smoldering furnace, and heat continuously at 60°C, and the expanded vermiculite particles After volatilization and condensation, the medium water is discharged from the condensed water outlet at the bottom of the smoldering furnace until the residual weight of the expanded vermiculite particles is ...

Embodiment approach 2

[0032] Embodiment two: as shown in Figure 1, the manufacture method of aromatherapy stone of the present invention, comprises the following steps:

[0033] 1. Get 1000 grams of expanded vermiculite particles, add 1500 grams of pure water, 12.5 grams of natural essential oil, 1 milligram of nano-gold aqueous solution and 1 milligram of nano-silver aqueous solution, wherein the weight of nano-gold aqueous solution Concentration is 5050PPM; The weight concentration of described nano-silver aqueous solution is 5050PPM;

[0034] ②. Put the above-mentioned expanded vermiculite particles adsorbed with pure water, natural essential oil, nano-gold aqueous solution, and nano-silver aqueous solution into a smoldering pan, then put them into a smoldering furnace, and heat continuously at 70°C, and the expanded vermiculite particles After volatilization and condensation, the medium water is discharged from the condensed water outlet at the bottom of the smoldering furnace until the residua...

Embodiment approach 3

[0036] Embodiment three: as shown in Figure 1, the manufacture method of the aromatherapy stone of the present invention comprises the following steps:

[0037] 1. Get 1000 grams of expanded vermiculite particles, add 2000 grams of pure water, 20 grams of natural essential oil, 10 mg of nano-gold aqueous solution and 10 mg of nano-silver aqueous solution, wherein the weight of nano-gold aqueous solution The concentration is 10000PPM; the weight concentration of the nano-silver aqueous solution is 50000PPM;

[0038] ②. Put the above-mentioned expanded vermiculite particles adsorbed with pure water, natural essential oil, nano-gold aqueous solution, and nano-silver aqueous solution into a smoldering pan, then put them into a smoldering furnace, and heat continuously at 80°C, and the expanded vermiculite particles After volatilization and condensation, the medium water is discharged from the condensed water outlet at the bottom of the smoldering furnace until the residual weight ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com