Method for extracting tea-seed oil

A technology of tea seed oil and tea seed, which is applied in the field of vegetable oil preparation, can solve the problems of immature tea seed oil technology, unsatisfactory demulsification effect, low extraction rate of tea seed oil, etc., and meet the requirements of good physical and chemical quality of the product and equipment Not high, the effect of fragrance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

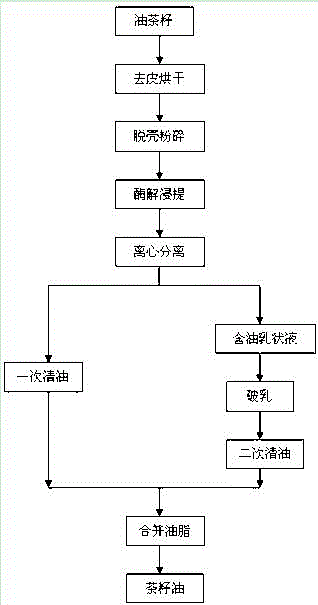

Image

Examples

Embodiment 1

[0020] A method for extracting tea seed oil, which is characterized in that: peeling and drying camellia seeds, shelling and pulverizing, enzymatic extraction, centrifugal separation, demulsification, and merging of oils and fats to obtain the finished product of tea seed oil;

[0021] Its concrete method comprises the following steps:

[0022] 1) Peeling and drying: After peeling the fresh camellia seeds, remove the moldy, diseased and insect-damaged seeds, spread them evenly on the material tray, and carry out hot air drying. The drying temperature is controlled at 60°C to reduce the water content to 6%;

[0023] 2) Shelling and crushing: adopt the method of mechanical shelling, put the dried camellia seeds into the tea seed sheller to break the shells, separate the kernels and shells through wind separation, and crush the shelled camellia seeds, And pass through a 70-mesh sieve for later use;

[0024] 3) Enzymatic hydrolysis and extraction: put the sieved camellia seeds i...

Embodiment 2

[0029] A method for extracting tea seed oil, which is characterized in that: peeling and drying camellia seeds, shelling and pulverizing, enzymatic extraction, centrifugal separation, demulsification, and merging of oils and fats to obtain the finished product of tea seed oil;

[0030] Its concrete method comprises the following steps:

[0031] 1) Peeling and drying: After peeling the fresh camellia seeds, remove the moldy, diseased and insect-damaged seeds, spread them evenly on the material tray, and carry out hot air drying. The drying temperature is controlled at 60°C to reduce the water content to 6%;

[0032] 2) Shelling and crushing: adopt the method of mechanical shelling, put the dried camellia seeds into the tea seed sheller to break the shells, separate the kernels and shells through wind separation, and crush the shelled camellia seeds, And pass through a 70-mesh sieve for later use;

[0033] 3) Enzymatic hydrolysis and extraction: put the sieved camellia seed in...

Embodiment 3

[0038] A method for extracting tea seed oil, which is characterized in that: peeling and drying camellia seeds, shelling and pulverizing, enzymatic extraction, centrifugal separation, demulsification, and merging of oils and fats to obtain the finished product of tea seed oil;

[0039] Its concrete method comprises the following steps:

[0040] 1) Peeling and drying: After peeling the fresh camellia seeds, remove the moldy, diseased and insect-damaged seeds, spread them evenly on the material tray, and carry out hot air drying. The drying temperature is controlled at 60°C to reduce the water content to 6%;

[0041] 2) Shelling and crushing: adopt the method of mechanical shelling, put the dried camellia seeds into the tea seed sheller to break the shells, separate the kernels and shells through wind separation, and crush the shelled camellia seeds, And pass through a 70-mesh sieve for later use;

[0042] 3) Enzymatic hydrolysis and extraction: put the sieved camellia seeds i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pov | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com