A kind of method for industrialized production of hemp protein oligopeptide

A technology of hemp protein and hemp seed is applied in the field of industrialized production of hemp protein oligopeptide, which can solve the problems of easily destroying the nutrients of hemp seed, poor color and luster of finished oligopeptides, and few protein oligopeptides. , to achieve the effect of accelerating the mass transfer rate and solubility, shortening the degreasing time, and protecting the activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A method for industrialized production of hemp protein oligopeptides, comprising the following steps:

[0032] S1: Crush hemp seeds and pass through a 10-mesh sieve, place them in an extraction tank, use subcritical extraction method for low-temperature degreasing, add butane to the extraction tank for 25 minutes according to the mass ratio of solid to liquid at 1:9, and repeat the extraction After 2 times, take out and obtain hemp seed powder after defatting; wherein, the operating conditions of the extraction tank are that the temperature is 20°C and the pressure is 0.03MPa;

[0033] S2: Add distilled water to the hemp seed powder after degreasing as described in S1 according to the material-to-liquid ratio of 1:8, and then put it in a colloid mill for grinding for 10 minutes to obtain a mixed solution;

[0034] S3 Alkaline Extraction: Add an acid-base regulator to the mixture described in S2, adjust the pH to 8.5, and put it in an ultrasonic-assisted extraction with ...

Embodiment 2

[0041] A method for industrialized production of hemp protein oligopeptides, comprising the following steps:

[0042] S1: Crush hemp seeds and pass through a 60-mesh sieve, place them in an extraction tank, use subcritical extraction method for low-temperature degreasing, add butane to the extraction tank for 30 minutes according to the mass ratio of solid to liquid at 1:10, and repeat the extraction After 2 times, take out and obtain hemp seed powder after defatting; wherein, the operating conditions of the extraction tank are that the temperature is 25°C and the pressure is 0.05MPa;

[0043] S2: Add distilled water to the hemp seed powder after degreasing as described in S1 according to the material-to-liquid ratio of 1:12, and then put it in a colloid mill for grinding for 15 minutes to obtain a mixed solution;

[0044] S3 Alkaline Extraction: Add an acid-base regulator to the mixed solution described in S2, adjust the pH value to 9.5, and put it in an ultrasonic-assisted e...

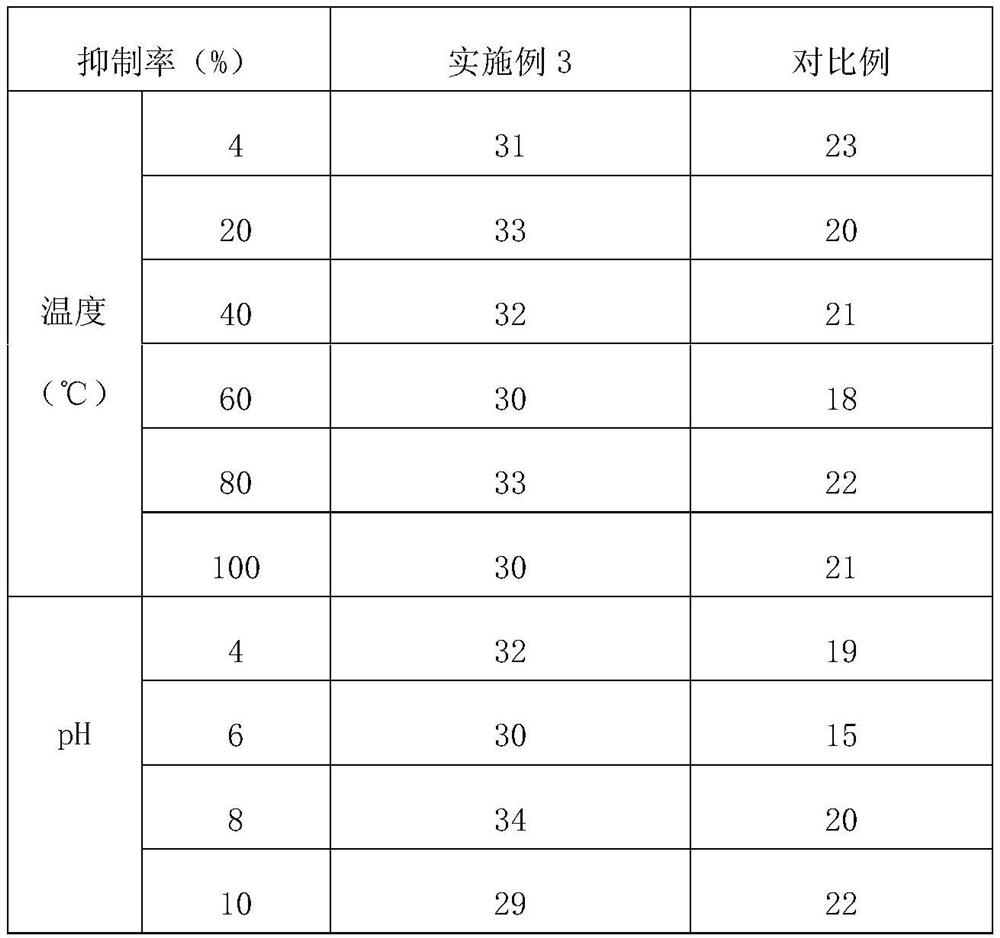

Embodiment 3

[0051] A method for industrialized production of hemp protein oligopeptides, comprising the following steps:

[0052] S1: Crush hemp seeds and pass through a 40-mesh sieve, place them in an extraction tank, use subcritical extraction method for low-temperature degreasing, add butane to the extraction tank for 28 minutes according to the mass ratio of solid to liquid at 1:9.5, and repeat the extraction After 2 times, take out and obtain hemp seed powder after defatting; wherein, the operating conditions of the extraction tank are that the temperature is 23°C and the pressure is 0.04MPa;

[0053] S2: add distilled water to the hemp seed powder after degreasing as described in S1 according to the material-to-liquid ratio of 1:10, and then put it in a colloid mill for grinding for 12 minutes to obtain a mixed solution;

[0054] S3 Alkaline Extraction: Add an acid-base regulator to the mixed solution described in S2, adjust the pH value to 9, and put it in an ultrasonic-assisted ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com