A kind of improved processing technology of Ganoderma lucidum slices by broiling method

A processing technology, the technology of ganoderma lucidum tablets, applied in the field of processing technology of ganoderma lucidum tablets, can solve the problems of low public acceptance and difficulty in popularization and application, and achieve the effects of suppressing bias, enhancing curative effect, and improving taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] This embodiment includes the following steps:

[0016] (1) Cut Ganoderma lucidum slices into 4-6cm lengths;

[0017] (2) Weigh a certain amount of brown sugar powder, add water equivalent to 4 times the volume of brown sugar powder to dissolve, and make brown sugar water;

[0018] In order to speed up the dissolution, add hot water at 50°C to dissolve;

[0019] (3) Take a closed container with a lid, mix the brown sugar water and Ganoderma lucidum tablets according to the mass-volume ratio of Ganoderma lucidum tablets: brown sugar water = 2g: 1mL, mix well, and moisten for 30min;

[0020] (4) Spread out the Ganoderma lucidum slices, place them in a drying oven, and dry them at 60°C for 24 hours.

Embodiment 2

[0022] This embodiment includes the following steps:

[0023] (1) Cut Ganoderma lucidum slices into 4-6cm lengths;

[0024] (2) Weigh a certain amount of brown sugar powder, add water equivalent to 5 times the volume of brown sugar powder to dissolve, and make brown sugar water;

[0025] (3) Take a closed container with a lid, mix the brown sugar water and Ganoderma lucidum tablets according to the mass-volume ratio of Ganoderma lucidum tablets: brown sugar water = 3g: 1mL, mix well, and moisten for 35min;

[0026] (4) Spread out the Ganoderma lucidum slices, place them in a drying oven, and dry them at 70°C for 20 hours.

Embodiment 3

[0028] The flavors of the Ganoderma lucidum tablets (Sample A) obtained in Example 1 and the traditional commercial Ganoderma lucidum tablets (Sample B) were compared, and descriptive analysis and consumer tests of food sensory inspection were carried out.

[0029] 1. Quantitative descriptive analysis

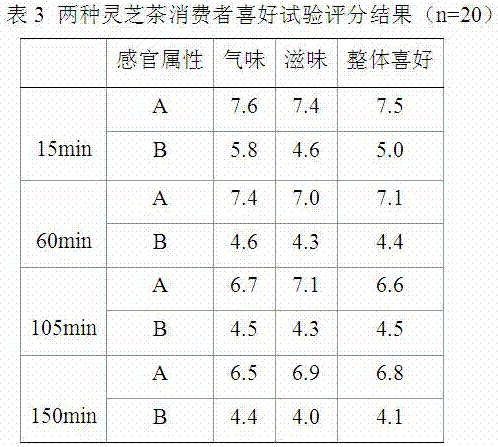

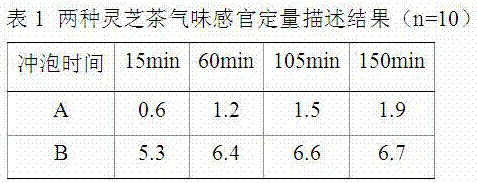

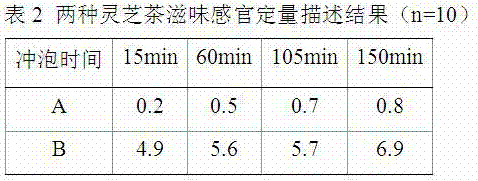

[0030] The evaluation team consisted of 10 screened, trained sensory evaluators, 3 males and 7 females, aged 20 to 24 years. The score is based on a 7-point system, 0-7 (0 means no taste, 7 means the strongest taste), and the odor (fungus odor) and taste (bitterness) of the two kinds of Ganoderma lucidum teas were evaluated respectively. Sample processing: Two kinds of Ganoderma lucidum teas of the same weight were brewed with the same amount of fresh boiled water, and the Ganoderma lucidum teas were taken at different time points for evaluation. The results are shown in Tables 1 and 2.

[0031]

[0032]

[0033] It can be seen from Table 1 that in the fungal odor score...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com