High capacity thin module system and method

A circuit module and type technology, which is applied in the structural connection of printed circuits, printed circuit components, etc., can solve problems such as deterioration of heat dissipation characteristics of DIMM circuit modules.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

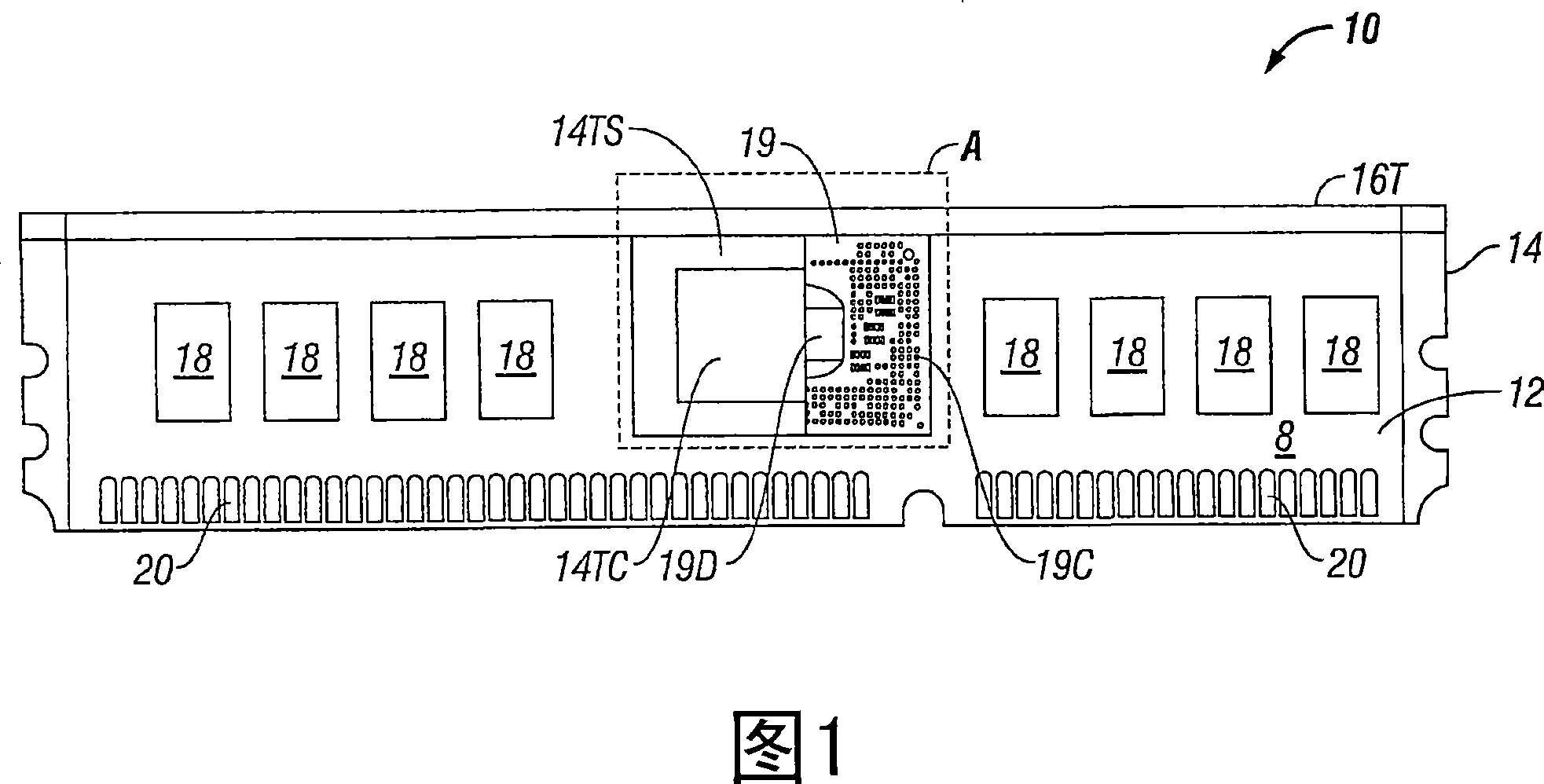

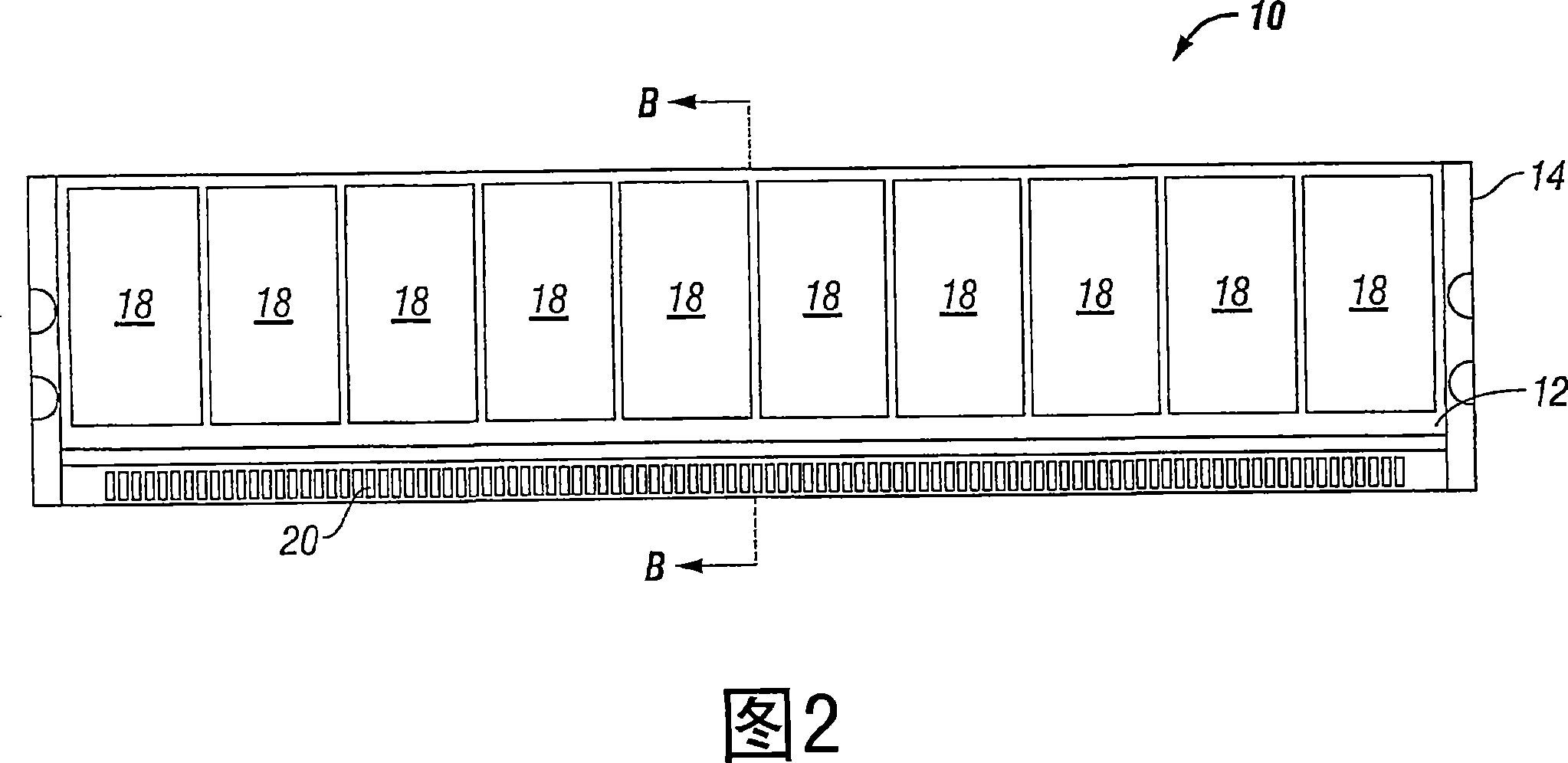

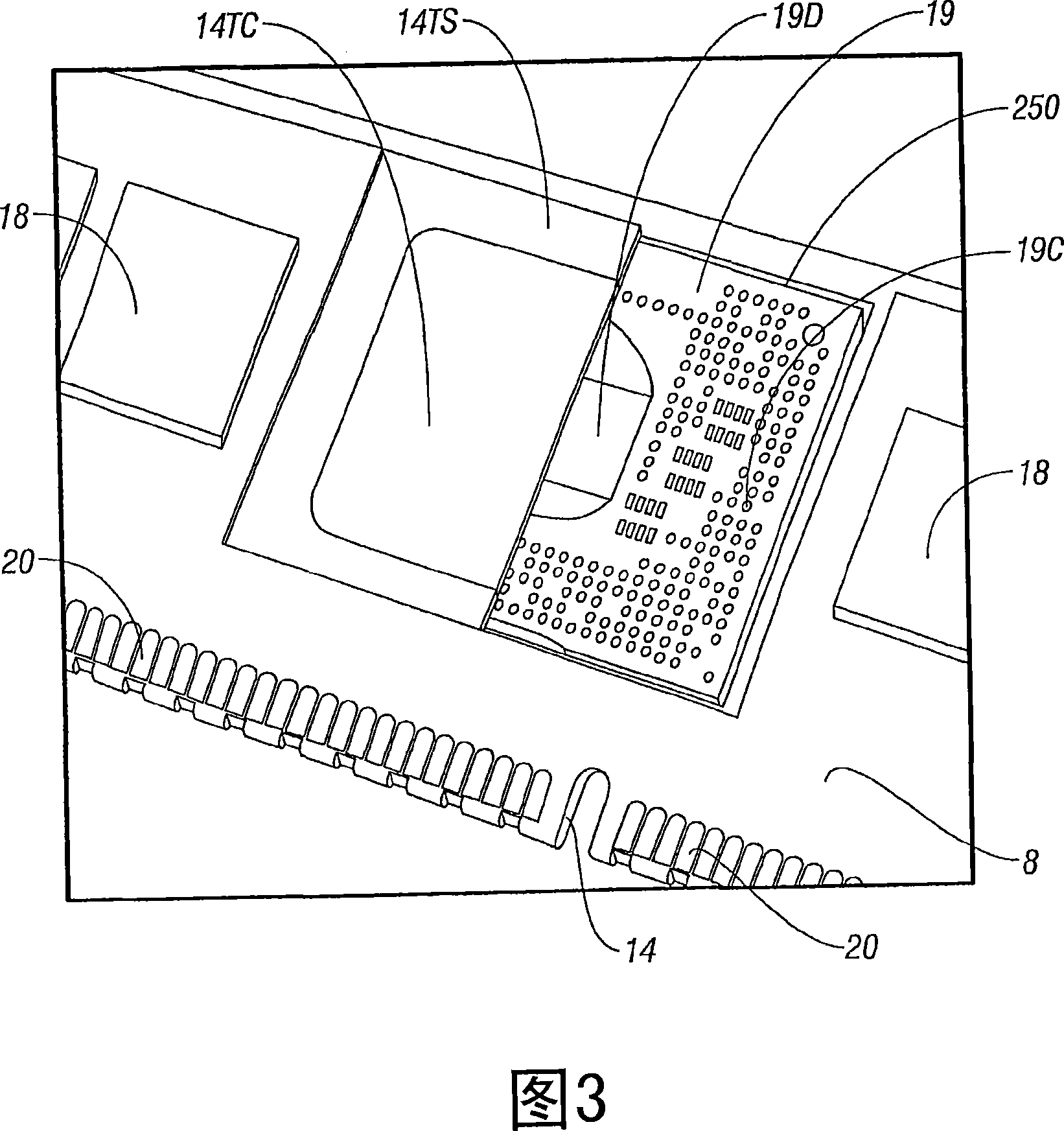

[0025] Figure 1 shows a module 10 designed in accordance with a preferred embodiment of the present invention. The diagram of FIG. 1 shows a module 10 having a substrate 14 near which is disposed a flex circuit 12 populated with an IC 18 which in a preferred embodiment is a memory device within a CSP package . Flex circuit 12 is shown in cross-section in area "A" to illustrate preferred features of the interior of module 10 . Area "A" is shown more enlarged in FIG. 3 below.

[0026] Heat sink 14TS is visible in area A, and in section beyond heat sink 14TS is shown a portion of circuitry 19 which, in the preferred embodiment, is a well-known advanced Memory Buffer or AMB. AMB circuit 19 includes AMB die 19D and contacts 19C. Typically, for example, a module according to a preferred embodiment will show a plurality of CSPs of a first type, such as a memory CSP, and will have at least one CSP of a second type, such as a microprocessor, graphics processor, or buffer, or More ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com