Temperature coefficient accurate setting electric resistor and manufacture thereof

A technology of temperature coefficient and manufacturing method, which is applied in the direction of resistance manufacturing, non-adjustable metal resistors, resistors, etc., can solve the problems of large error and large dispersion of temperature coefficient, and achieve the effect of accurate resistance value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The present invention will be further described in detail below in conjunction with the preferred embodiments shown in the accompanying drawings.

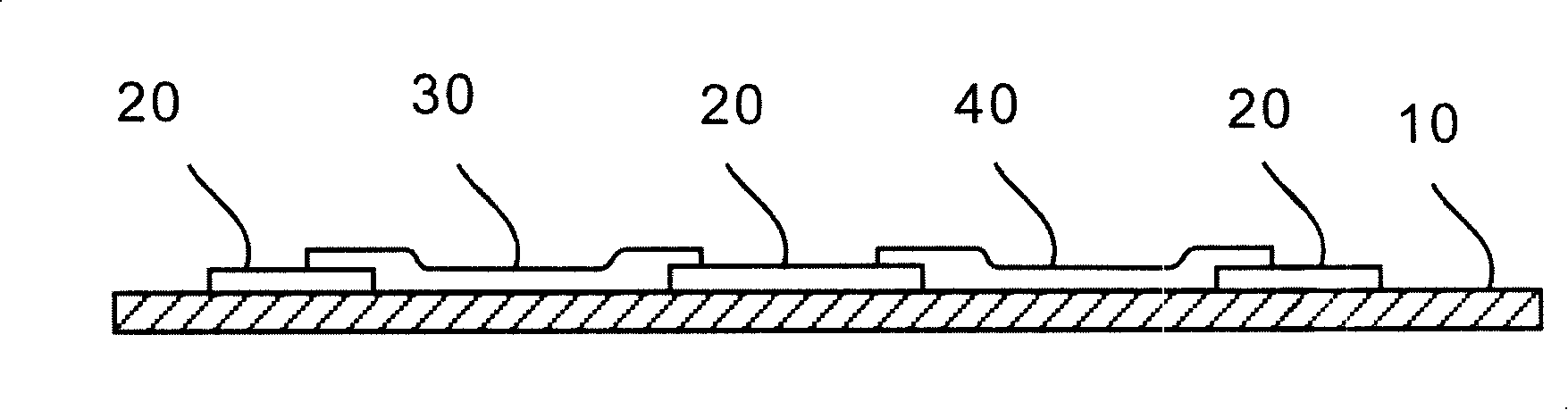

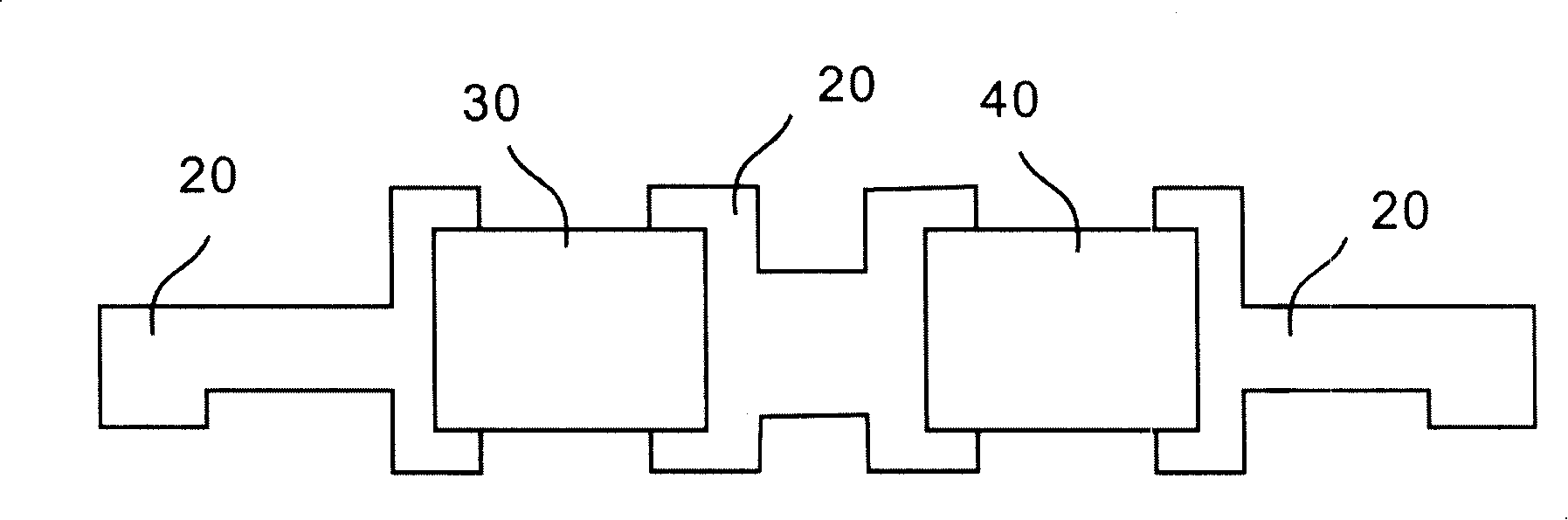

[0053] Such as Figure 1 to Figure 5 As shown, a method for manufacturing a resistor whose temperature coefficient can be precisely set is implemented, the method includes the steps of:

[0054] A. First carry out layout design and prepare a screen template, and prepare a high temperature resistant insulating substrate 10, and prepare the first thick film resistor paste and the second thick film resistor paste;

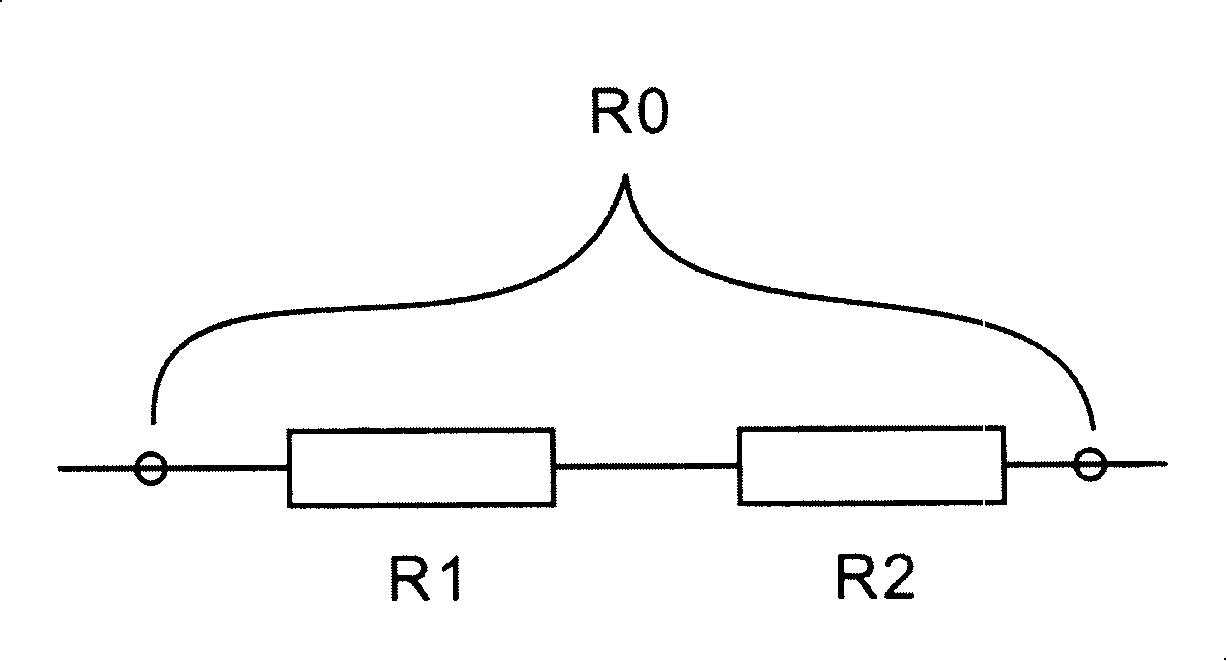

[0055] And the layout design determines the resistance value of the target resistor = the resistance value of the first thick film resistor 30 + the resistance value of the second thick film resistor 40, namely R 0 =R 1 +R 2 ;

[0056] The first kind of thick film resistor paste and the second kind of thick film resistor paste satisfy the relational expression during preparation: T CR1 CR0 CR2 ;

[0057] In th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com