Mold special for coupler yoke frame and demoulding method

A hook tail frame and mold technology, which is applied in the direction of manufacturing tools, forging/pressing/hammer devices, forging/pressing/hammering machinery, etc., can solve the problems of difficult positioning of shearing, high labor intensity, long time for hook tail frames, etc. , to achieve the effects of easy automation, labor saving and low labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

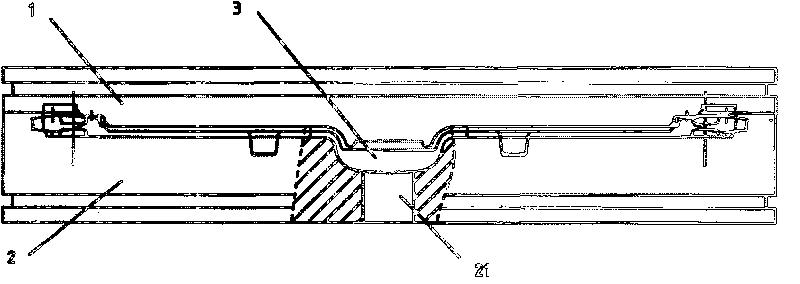

[0028] like figure 1 As shown, the special mold of the present invention comprises an upper mold 1 and a lower mold 2, a cavity 3 of the hooktail frame is formed between the upper mold 1 and the lower mold 2, and at least one through hole 21 is provided at the bottom of the lower mold 2. In this embodiment In an example, there is one through hole, and the upper end of the through hole 21 is connected to the cavity 3 . After the forging and pressing of the hook tail frame, it is only necessary to set a push rod in the through hole 21, and then act on the push rod to move upwards, and the hook tail frame connected to the upper end of the through hole 21 can be jacked up to realize quick demoulding .

Embodiment 2

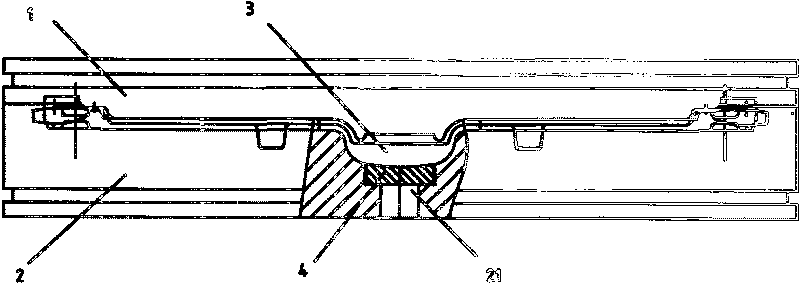

[0030] like figure 2 As shown, at least one through hole 21 is provided on the lower mold 2, and in this embodiment, there is one through hole, and a groove is also arranged at the position of the through hole 21 of the lower mold 1, and a groove is set in the groove There is a movable block 4, through hole 21 links to each other with the movable block 4, the shape of the movable block 4 can be circular, rectangular or any shape, the size of the upper surface area is determined according to the number of through holes, when there are many through holes, the movable block 4 The area of the movable block 4 can be relatively small, and a rod can be fixedly connected to the lower end of the movable block 4, and the rod passes through the through hole 21. After the hooktail frame is forged and formed by the die, the ejector rod in the through hole 21 first acts on the movable block 4, and then acts on the hooktail frame through the movable block 4, changing the small acting surf...

Embodiment 3

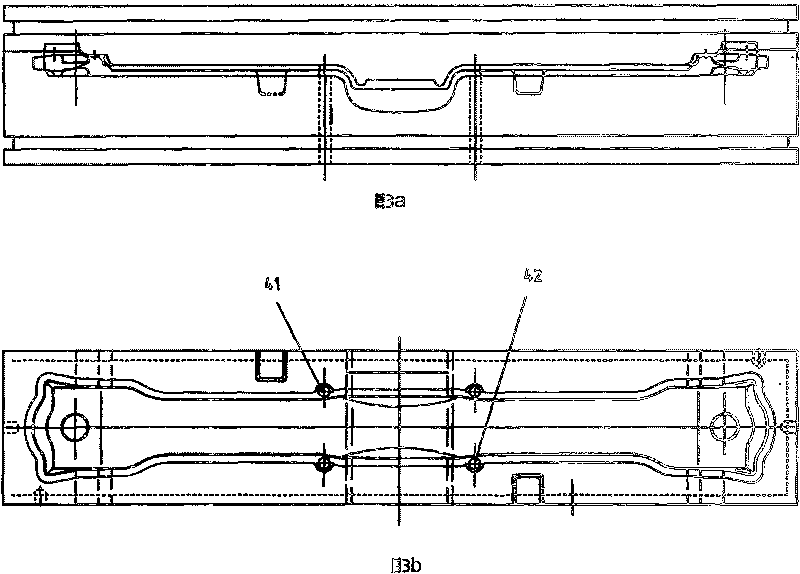

[0032] like image 3 As shown, at least one through hole is provided on the shell walls on both sides of the lower mold 2, and the position of the through hole is just at the position of the burr generated when the coupler frame is forged and pressed. In this embodiment, each side shell wall Each of the through holes on the top is two holes 41 and 42 respectively. After the coupler frame is forged and formed by the die, the ejector rod in the hole directly acts on the flash, and the deformation of the coupler frame will not occur while demolding.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com