Regenerating system and technique for three-tower waste aid

A regeneration system and waste acid technology, applied in chlorine/hydrogen chloride purification, chlorine/hydrogen chloride, dispersed particle separation, etc., can solve problems such as unstable iron powder quality, difficult process control, complex equipment structure, etc., to achieve a simple and reasonable structure , operation simplification, and the effect of ensuring operation safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

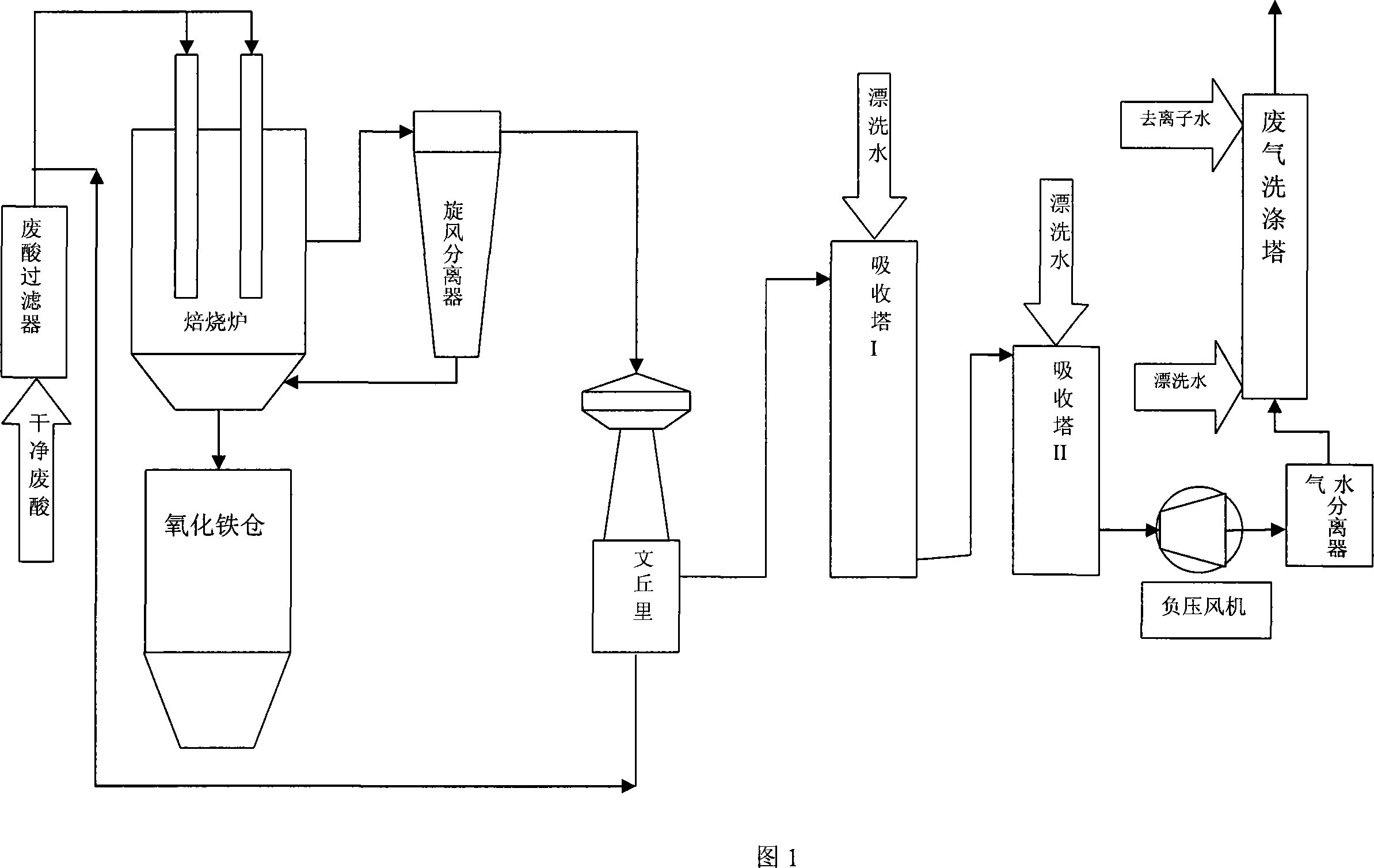

[0027] Below in conjunction with accompanying drawing and the present invention is further described.

[0028] The pickling waste from the pickling unit is collected in a spent acid tank whose storage capacity allows the regeneration unit to work independently of the pickling unit.

[0029] The acid in the acid storage tank is pumped to the spent acid filter, where solid particles and undissolved residues from the pickling operation are separated from the acid liquor.

[0030] The waste acid enters the pre-desilication unit through a pneumatically operated valve (see the process description of the pre-desilication unit). The waste acid liquid after pre-desiliconization and purification is collected and mixed in the purified waste acid tank in the tank area. The waste acid after pre-desiliconization enters the Venturi separator through a pneumatically operated valve, and the liquid level of the Venturi separator is automatically controlled by the pneumatic valve. The acid flo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com