Method for replacing bridge basin-type rubber support

A technology of rubber bearing and replacement method, applied in bridges, bridge parts, bridge maintenance and other directions, can solve the problems of small bearing capacity, large bearing bearing capacity, simple replacement method, etc., and achieve low cost and short time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

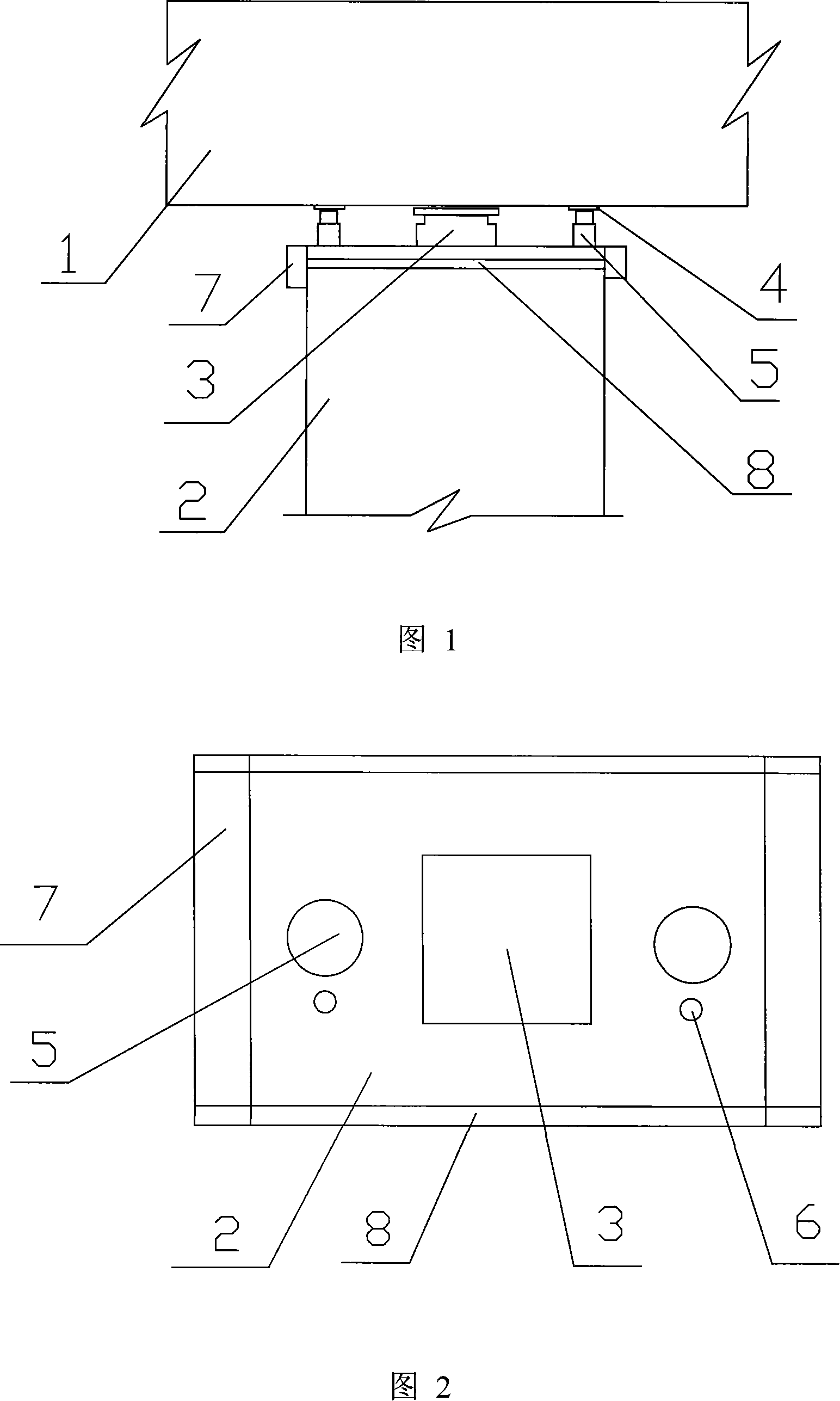

[0019] As shown in Figure 1 and Figure 2, there is a basin-type rubber bearing 3 between the box girder 1 and the pillar 2.

[0020] When replacing the support: place a 40cmx40cm steel plate 4 with a thickness of 20mm on both sides of the support 3, and place two flat hydraulic jacks 5 under the steel plate 4. The total working tonnage of the two jacks 5 and the bearing capacity of the support 3 Consistent, two flat hydraulic jacks 5 are on the symmetrical positions on both sides of the support 3; at the same time, a dial indicator 6 is installed near the support 5, and the tensioning oil pump is started to slowly lift the box girder 1, so that the steel plate on the support Keep in contact with the PTFE plate of the support but do not transmit the load; at this time, cut the anchor bolts on the support 3, remove the lower half of the support, and then chisel out the support pad stone to take out the upper steel plate of the support; then install the same Type new bearing, wel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com