Mini car and motorcycle general type turbo-charger

A turbocharger, motorcycle technology, applied in the machine/engine, engine seal, engine components and other directions, can solve the problem of no matching use of gasoline engine, achieve light weight, reduce fuel consumption, reduce the content of pollutant emissions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

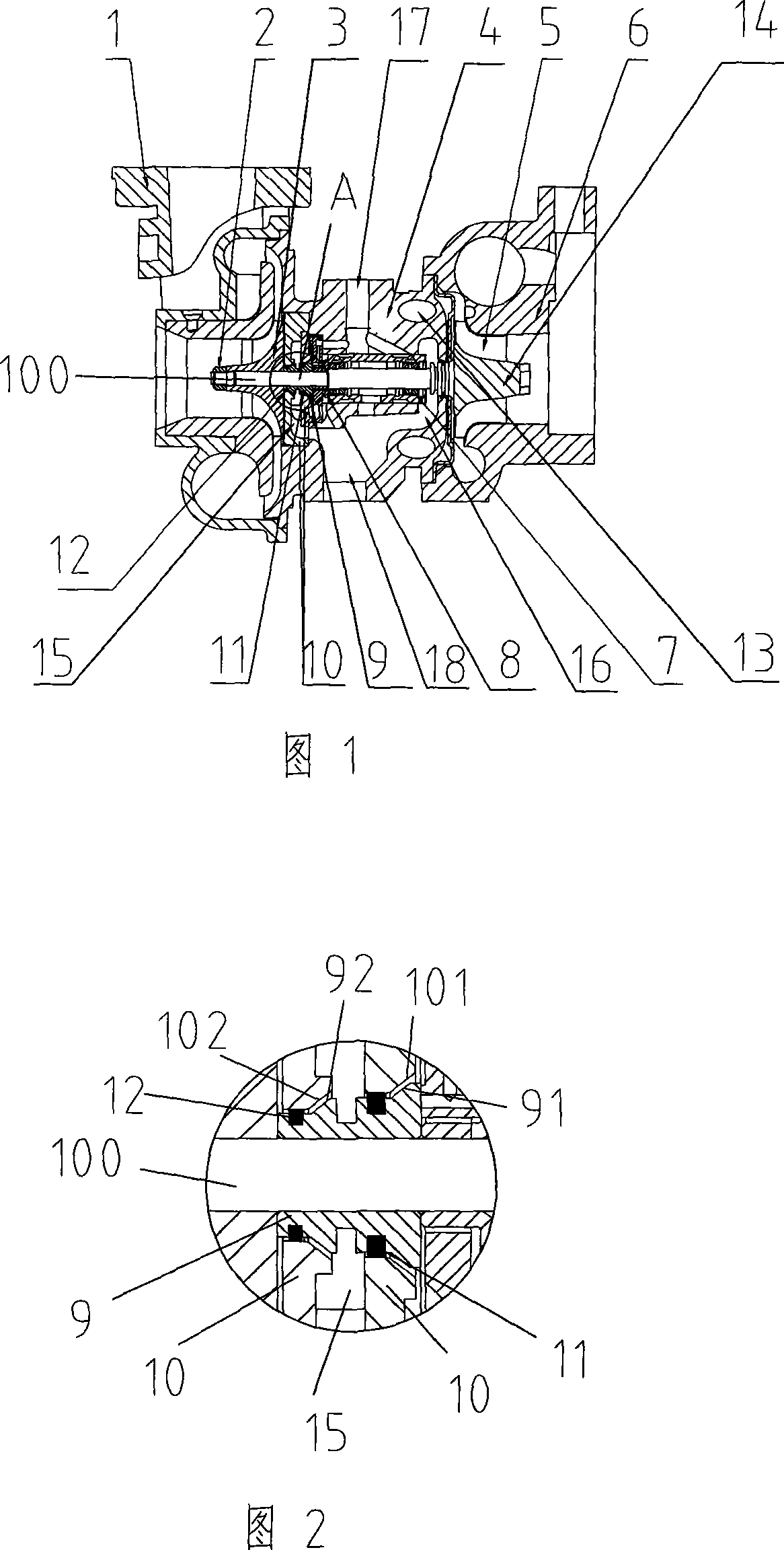

[0018] The structure of the universal turbocharger for miniature cars and motorcycles described in this embodiment is referring to accompanying drawing 1, and the compressor impeller 3 is placed in the compressor volute 1; The turbine impeller 14 is fixedly arranged on the turbine shaft 5, and the turbine shaft 5. The outer cover has a turbine shell 6; floating bearing 7, thrust plate 8, shaft seal 9, seal seat 10, seal rings 11, 12, cooling water channel 13 and oil return chamber 15, 16 are all placed in the bearing body 4. There is an oil inlet hole 17 at the upper end of the bearing body 4, and an oil return hole 18 at the lower end; the turbine impeller 14 is connected with the compressor impeller 3 through the rotating shaft 100, and the self-locking nut 2 compresses the compressor impeller 3, the shaft seal 9 and the thrust plate 8 and the turbine shaft 5 form a rotor assembly; the floating bearing 7 is placed on both sides of the rotating shaft 100; there are two sealing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com