Electricity plant condenser ball cleaning automatic monitoring device

An automatic monitoring and condenser technology, which is applied in the direction of cleaning heat transfer devices, non-rotating equipment cleaning, lighting and heating equipment, etc. Easy to operate and reduce labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

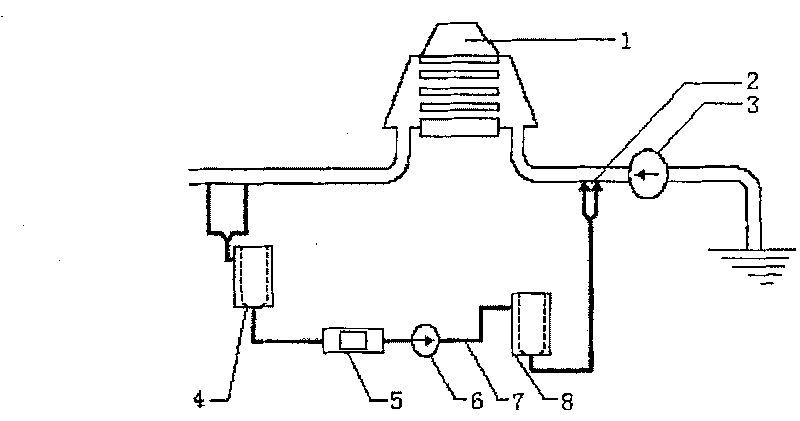

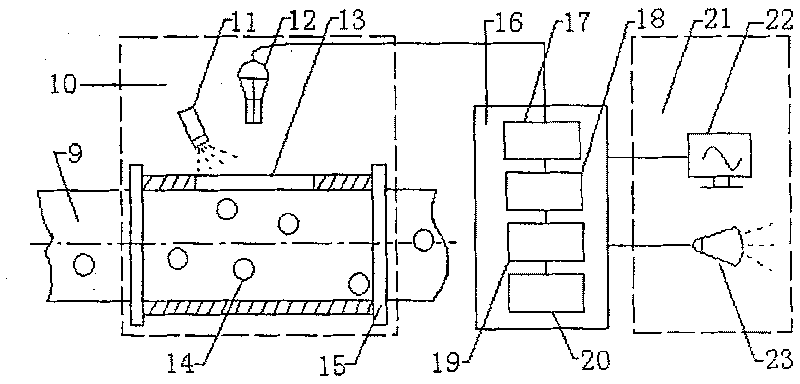

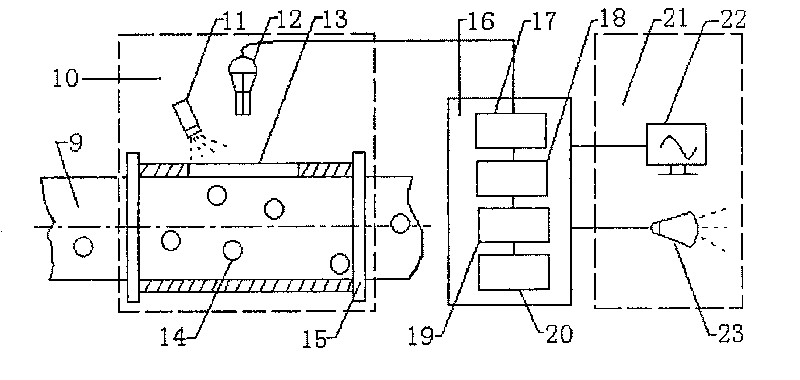

[0013] according to figure 1 The specific structure of the present invention will be described in detail with the embodiments. The device includes a shell connected to the rubber ball circulation pipeline 7 in the existing rubber ball cleaning device through flanges 15 at both ends and a monitoring and control circuit thereof. The rubber ball cleaning device of existing condenser 1 generally all is made up of components such as ball receiving chamber 4, rubber ball pump 6, rubber ball circulation pipeline 7, ball loading chamber 8, rubber ball nozzle 2 with ball collecting net. With the help of high-pressure water flow, it squeezes the cleaning rubber ball larger than the inner diameter of the cooling tube of the condenser 1 through the cooling tube, repeatedly scrubs the cooling tube, cleans the dirt in the cooling tube of the condenser and takes out impurities.

[0014] The position of the monitoring device 5 is just arranged between the rubber ball pump 6 and the ball coll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com