Heat bonding enamelling wire high-temperature bond strength experimental method and device

A technology of bonding strength and experimental method, applied in the field of transformers, can solve problems such as changes in mechanical properties of transposition lines, component design errors, inability to accurately reflect the bonding strength data of thermally bonded enameled wires, etc. Achieving the effect of simple device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

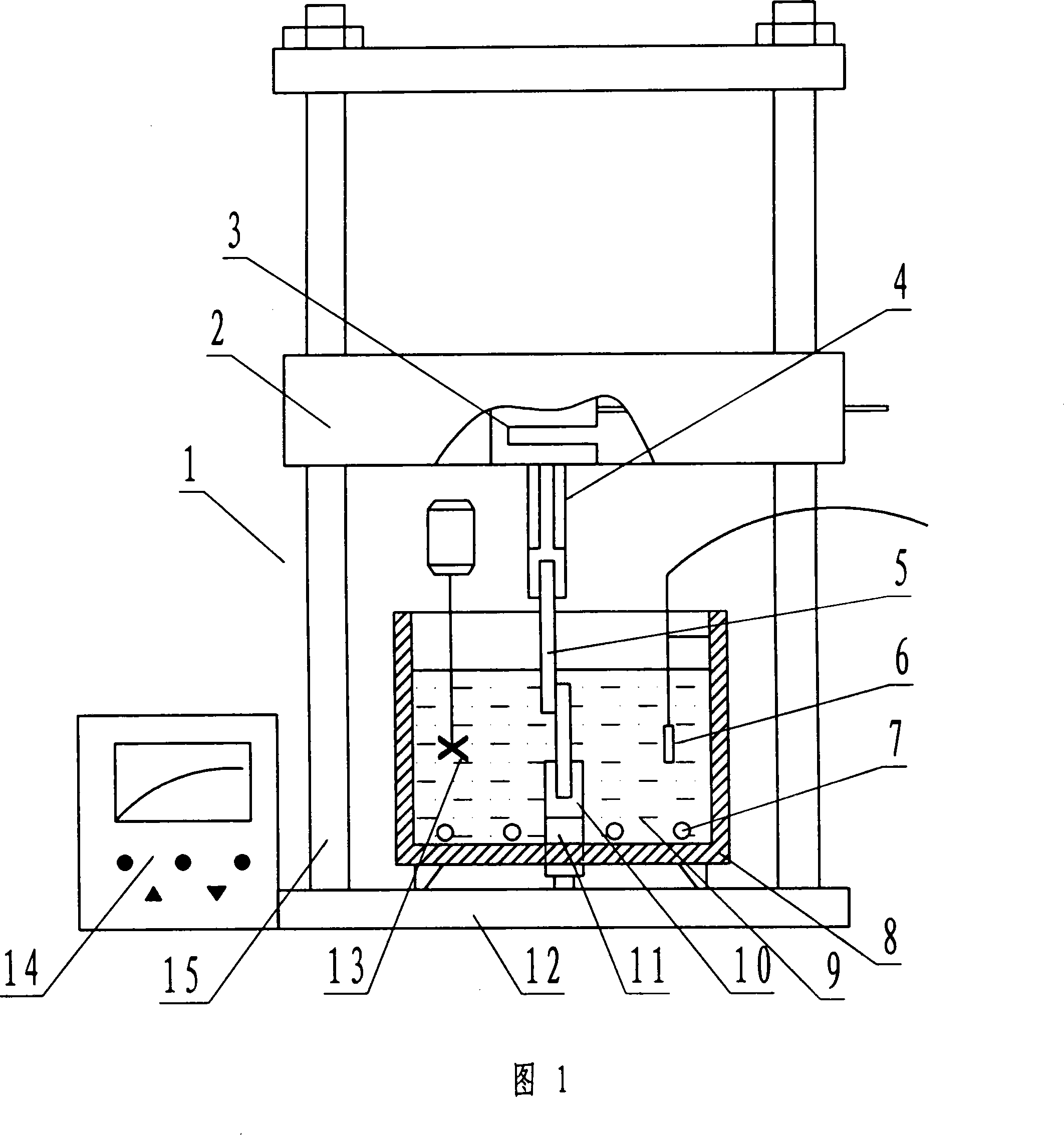

[0016] The invention uses a special experimental device to simulate the operating environment of the transformer, and conducts a high-temperature adhesive strength experiment of thermally bonded enameled wires in the environment, and obtains experimental data of the experiment under the actual operating condition of the transformer.

[0017] Referring to Fig. 1, the experimental device of the present invention comprises a test mechanism 1 and an oil bath 8 containing silicone oil 9. The test mechanism includes a base 12, a crossbeam 2, a guide post 15 and a display 14. The two guide posts are slidably connected to the crossbeam, and the crossbeam The upper chuck 4 is set at the place. The oil bath test box is located on the base, and there is a support 11 inside. The support is integrated with the oil bath test box and passes through the bottom of the oil bath test box to be connected with the base 12. The upper part of the support is provided with a lower chuck 10. An electri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com