In situ quantitative determination method for large-sized metallic inclusion

An in-situ quantification and inclusion technology, which is used in testing metals, preparation of samples for testing, material inspections, etc. It can solve problems such as inability to ensure consistent distribution and inability to accurately analyze the in-situ distribution of inclusions in steel.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

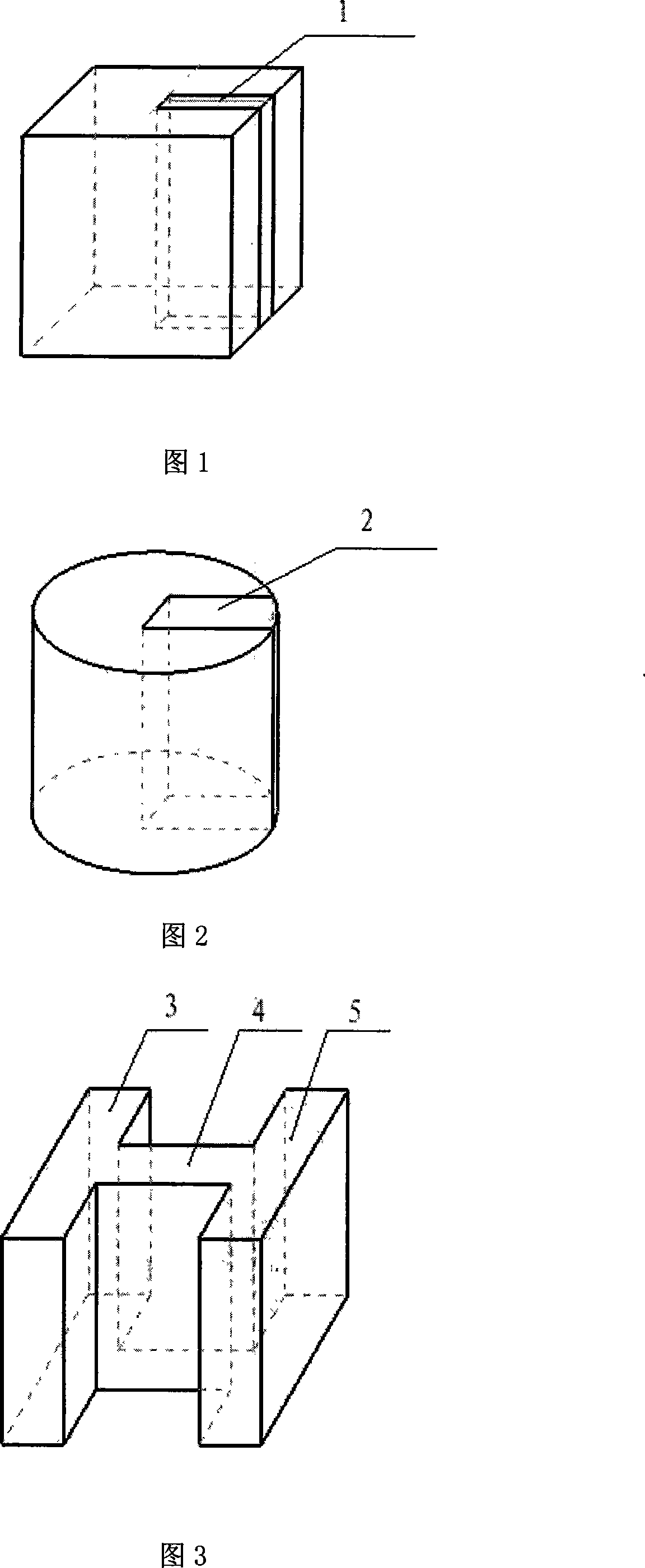

[0025] Example 1: Determination of SS400 slab inclusions, the sampling is shown in Figure 1.

Embodiment 2

[0026] Example 2: Determination of inclusions in 20MnSi rods, the sampling is shown in Figure 2.

Embodiment 3

[0027] Example 3: Determination of inclusions in Q235B H-shaped steel, as shown in Figure 3 for sampling.

[0028] The chemical composition of embodiment 1-3 steel kind is shown in Table 1:

[0029] Table 1

[0030] C(%)

Si(%)

Mn(%)

P(%)

S(%)

SS400 slab

0.17

0.12

0.40

0.025

0.01

20MnSi rod

0.21

0.65

1.55

0.045

0.045

Q235B H-beam

0.14

0.18

0.50

0.018

0.02

[0031] The method for in-situ quantitative detection of large metal inclusions, the steps are as follows:

[0032] (1) Sampling and sample preparation

[0033] For the continuous casting slabs, bars or H-beams of Examples 1-3, respectively cut 200mm long cross-sections, cut 20mm wide samples longitudinally from the surface to the core, clean the surface, coat the resin adhesive layer, and only keep The surface of the original steel is not...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com