Optical fibre electric current sensor all-optical fibre sensing head

A fiber optic current, all-fiber technology, applied in the direction of voltage/current isolation, etc., can solve the problems of erroneous output, heavy sensor head, complicated installation process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

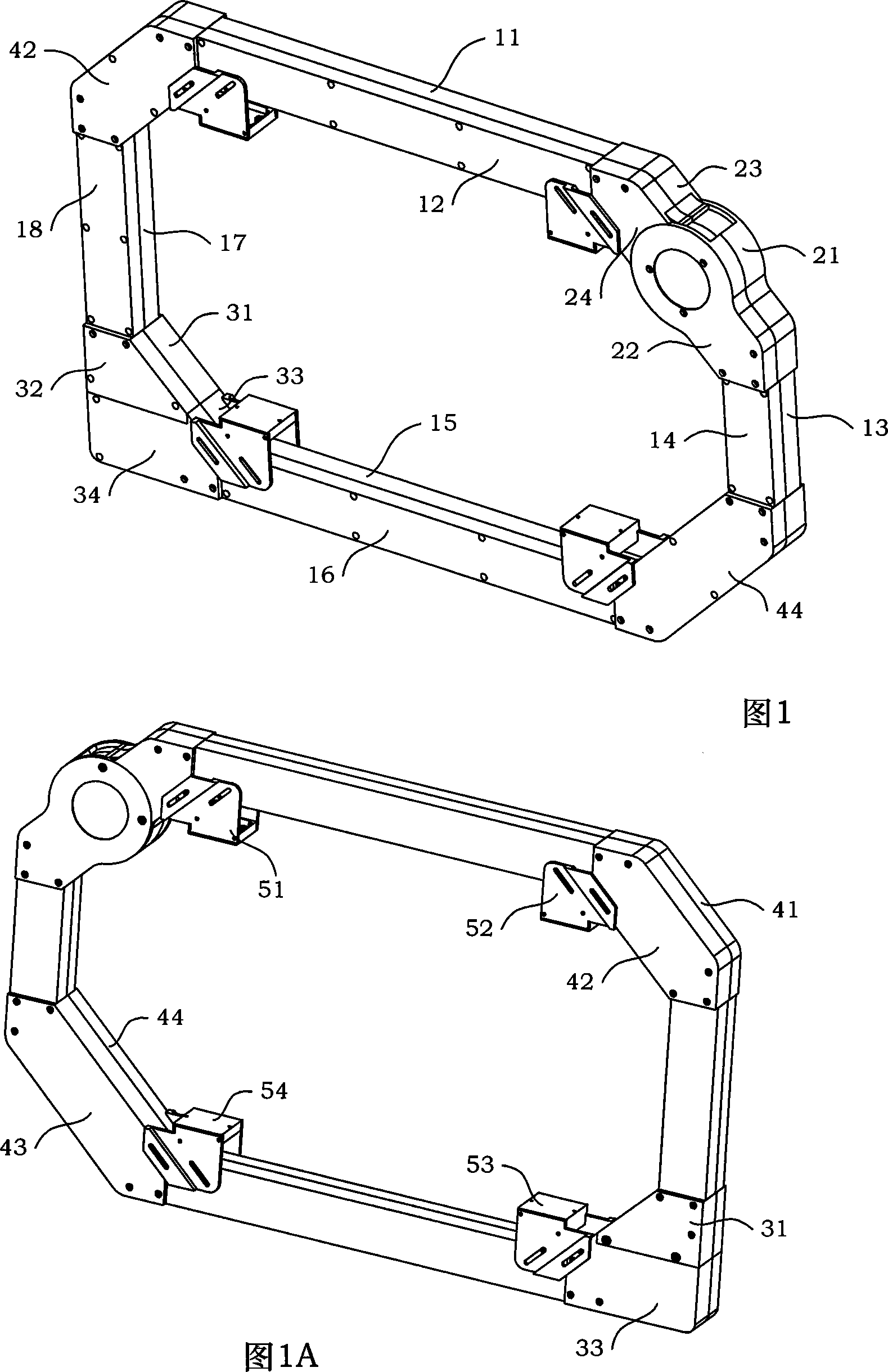

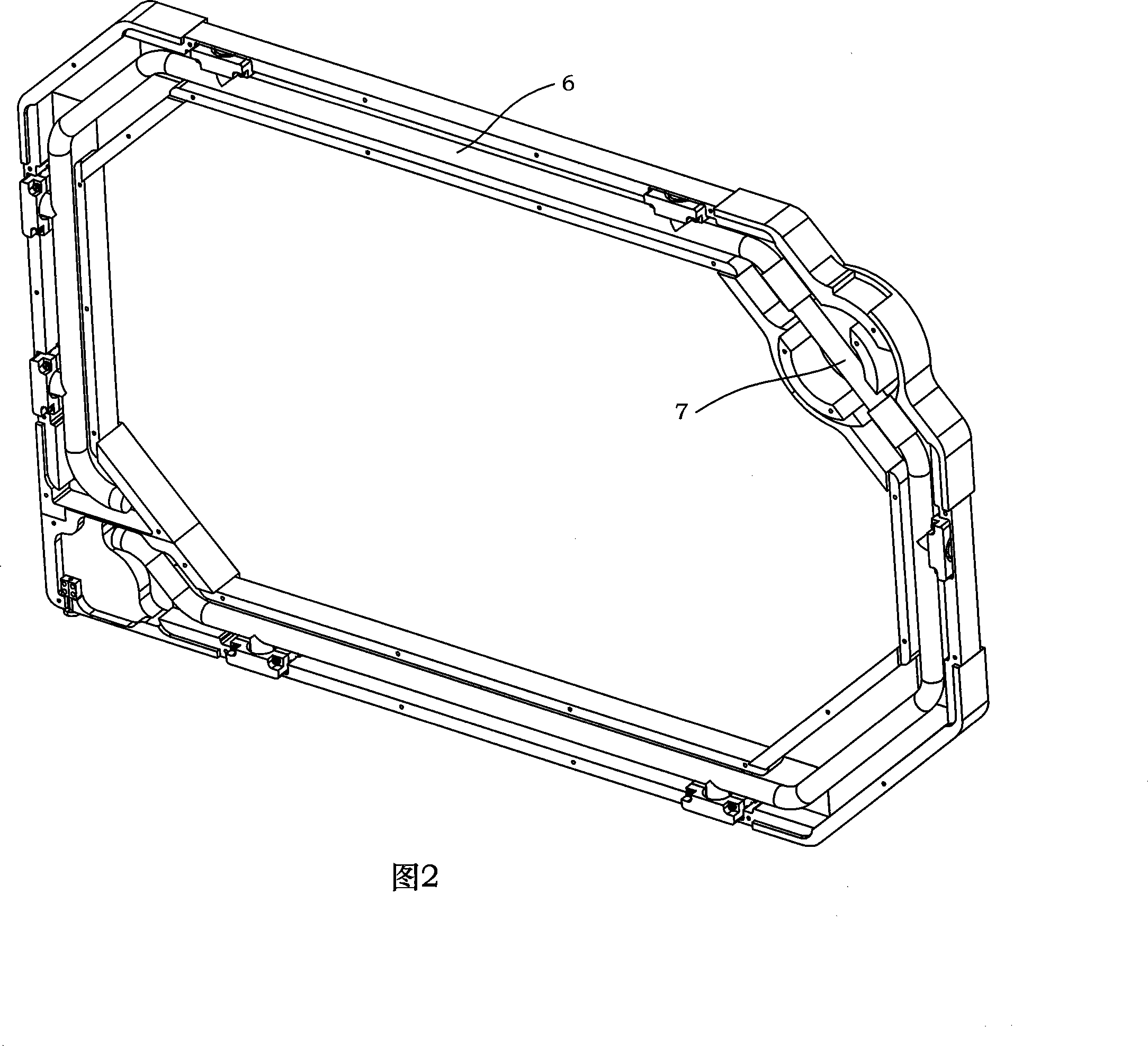

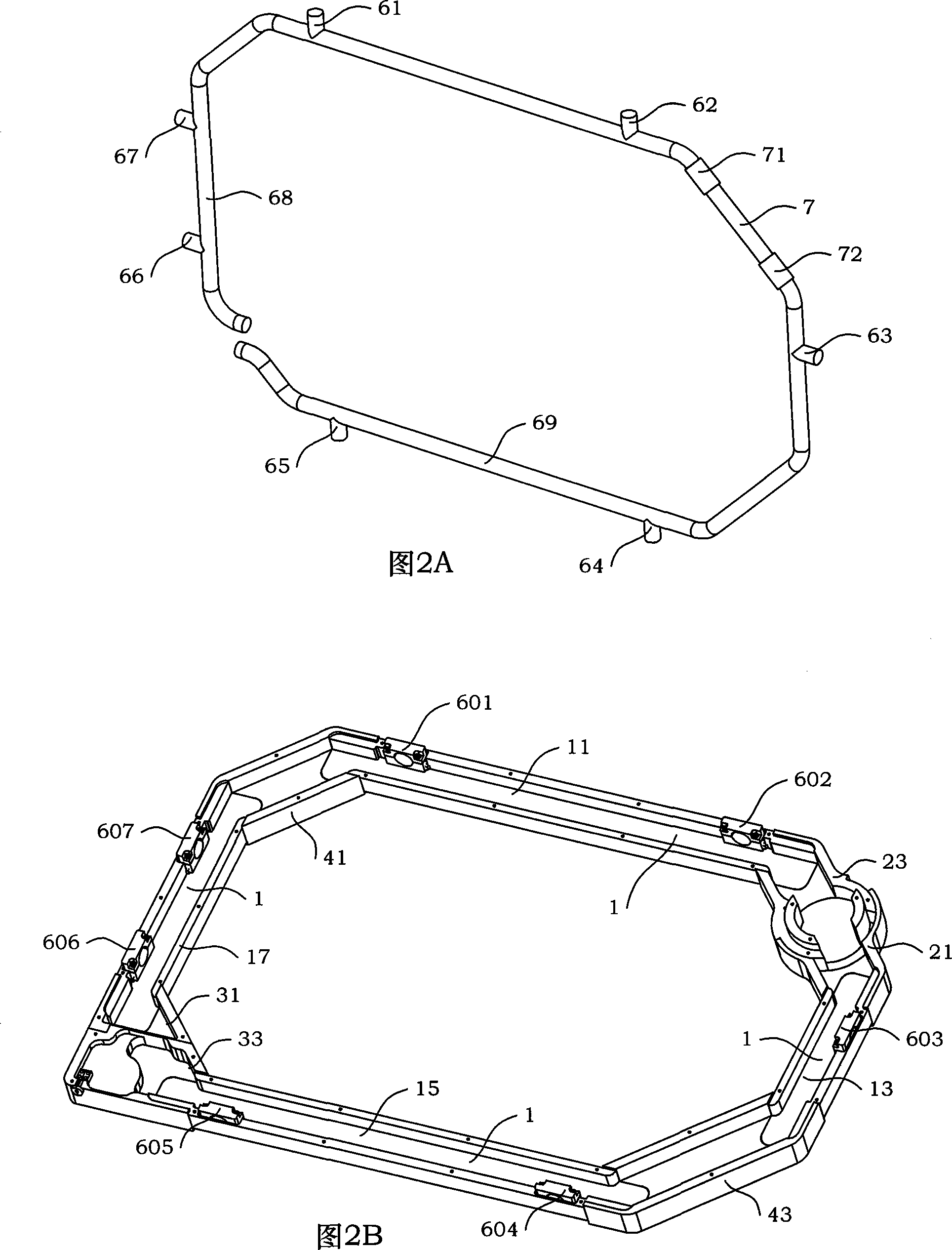

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings.

[0025] The all-fiber sensor head architecture of the present invention is designed to solve the problem that the existing sensor head architecture cannot easily realize on-site installation and disassembly. The all-fiber sensor head architecture of the present invention can be installed and disassembled with electricity, and has a short assembly and disassembly time; The modular design concept can realize the miniaturized structure design and effectively solve the weight and volume of the sensor head structure. When the sensor head of the present invention is installed and disassembled, the opening width is greater than 300mm. That is, the distance between the upper plate 32 of the connecting corner A and the lower plate 31 of the connecting corner A after being connected to the upper plate 34 of the connecting corner B and the lower plate 33 of the connecting co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com