Paper-free three-dimensional assemblage process document accomplishing method

A technology of assembly process and implementation method, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problem that the CAAPP system assembly process design method cannot meet the high efficiency of manufacturing system, high information integration, and cannot meet the product development cycle and other issues to achieve the effect of shortening the assembly cycle, facilitating preparation, and improving operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

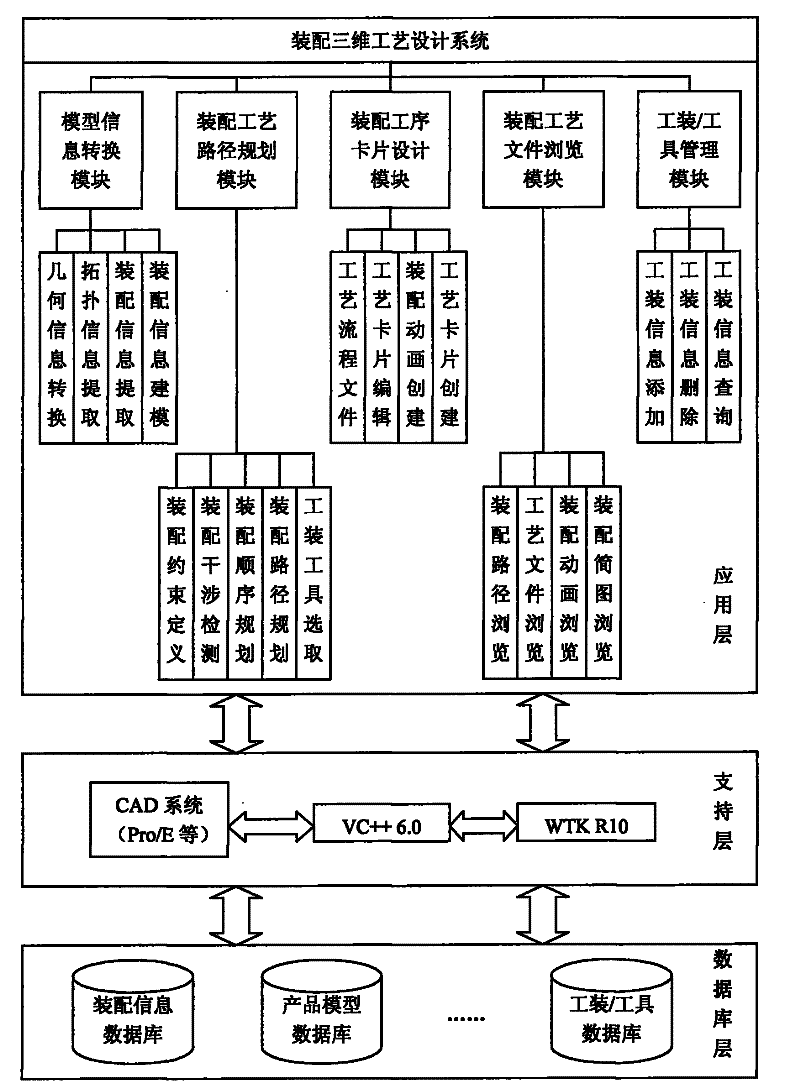

[0031] Such as Figure 1-5 shown.

[0032] A method for realizing a paperless three-dimensional assembly process document, which includes the following steps:

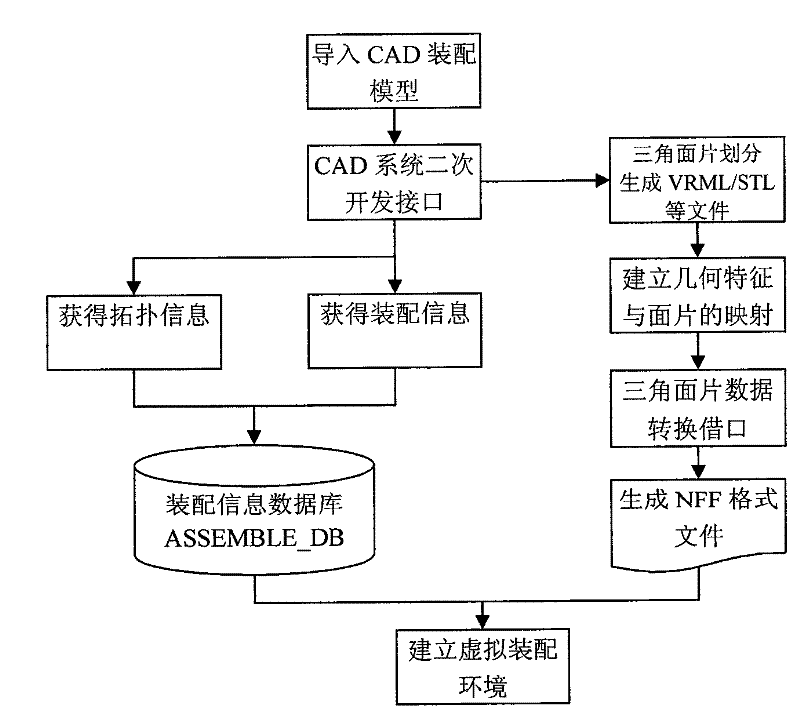

[0033] Firstly, the process designer retrieves the CAD assembly file of the product to be assembled from the product design database, uses the CAD secondary development interface program to read the hierarchical information and constraint information of the CAD assembly model file, establishes a constraint list, and re-does it by the program The topological information and assembly information of the generated parts are organized and stored in the assembly information database ASSEMBLY_DB, such as figure 2 shown;

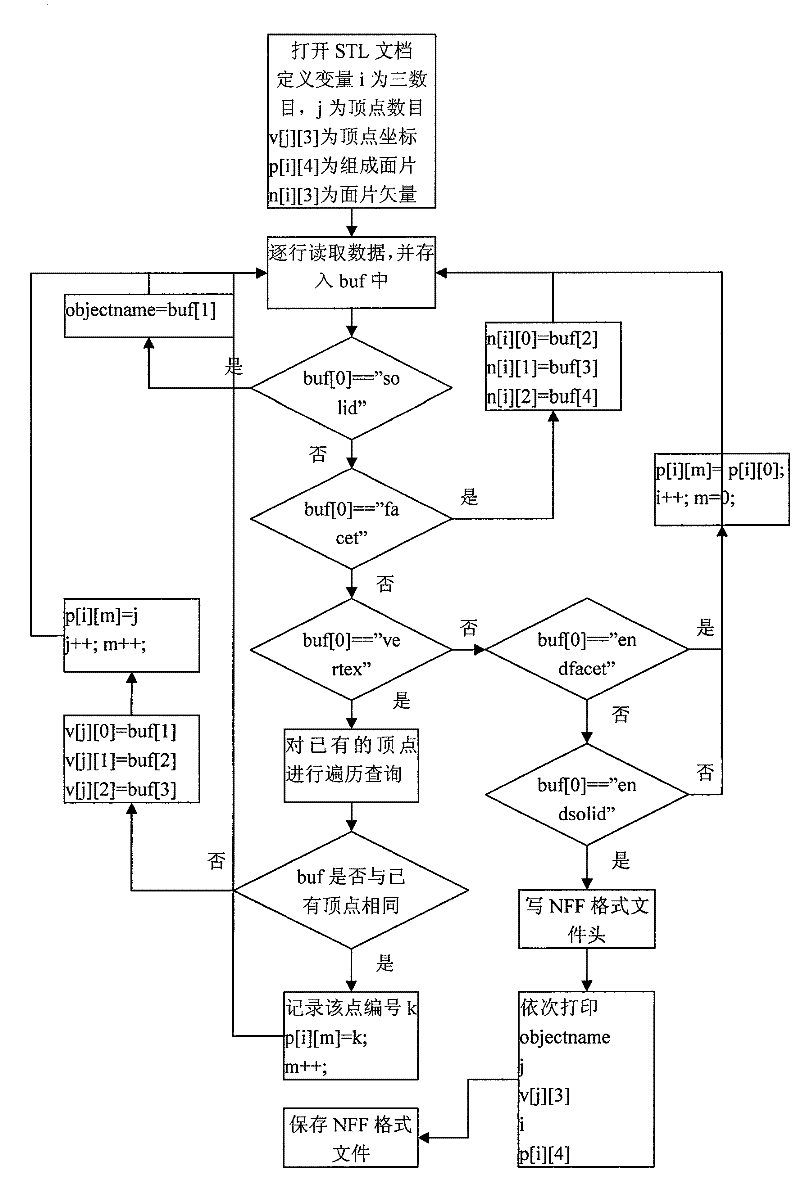

[0034] Secondly, use CAD software to segment the CAD design model of the part into triangular patches, generate triangular patch files (such as STL, VRML, etc.), and then establis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com