Crane with heavy frame beam

A crane, heavy-duty technology, applied in the direction of crane, traveling mechanism, load hanging element, etc., to achieve the effect of improving construction quality and progress, simple structure and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with accompanying drawing:

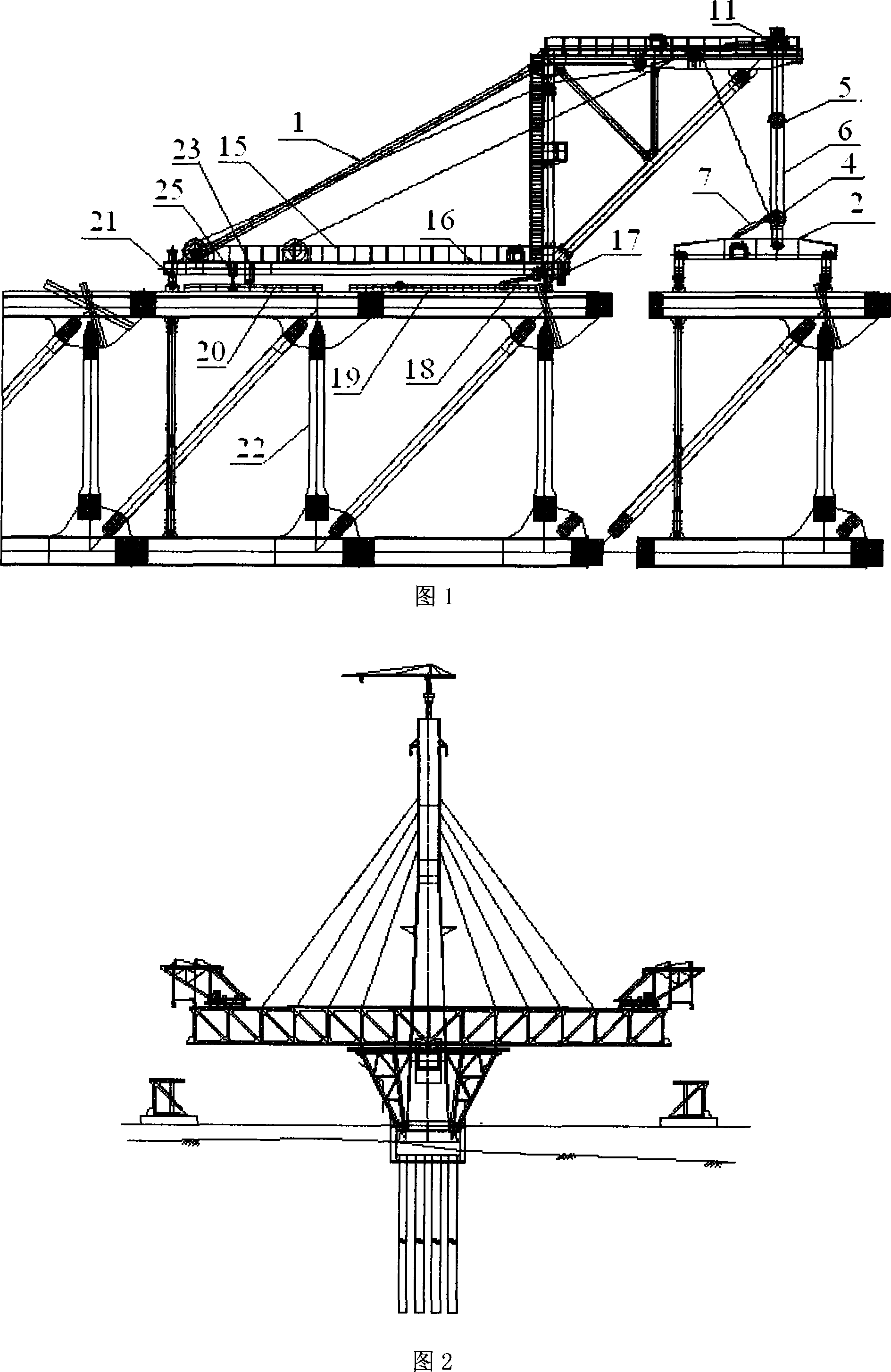

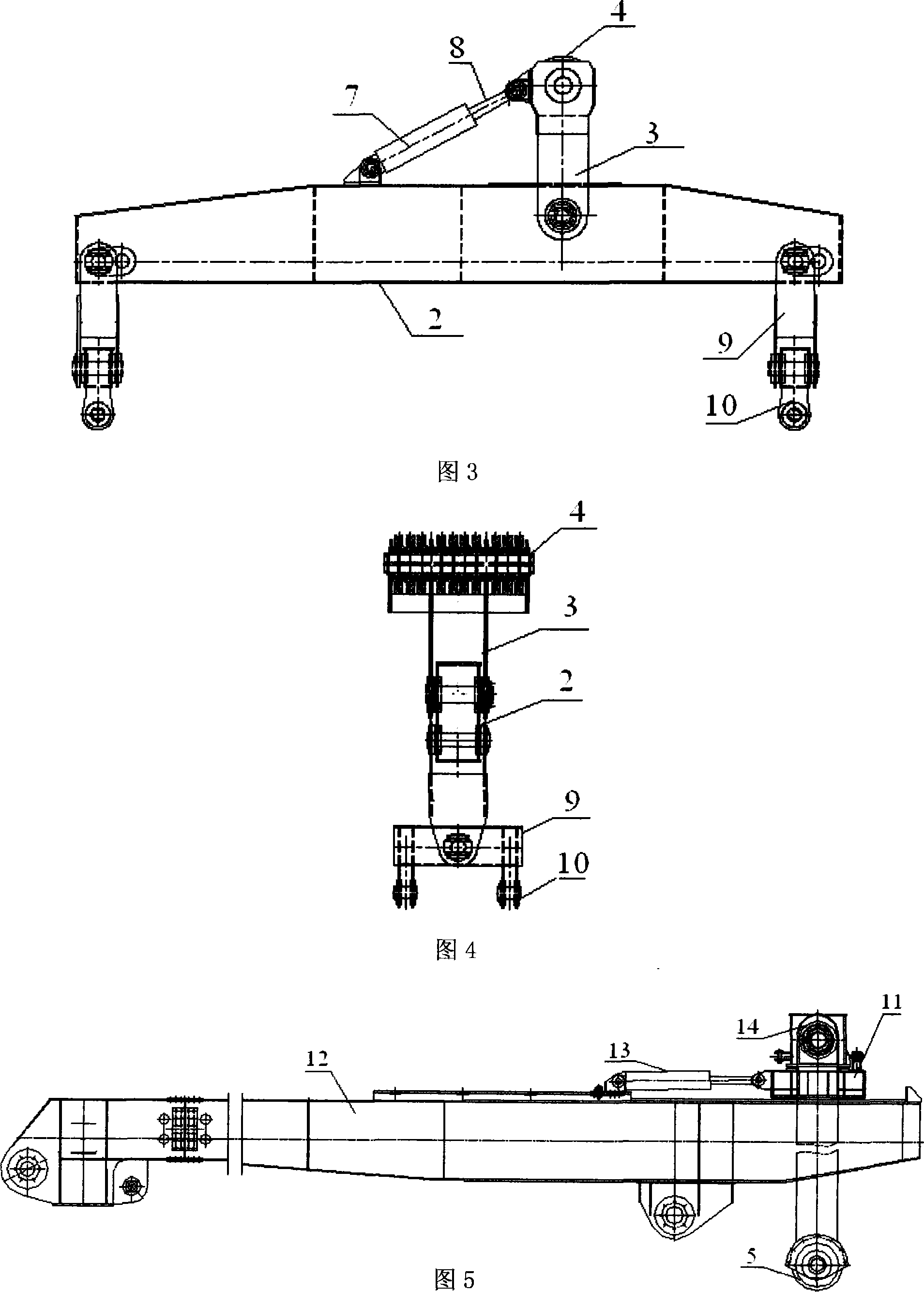

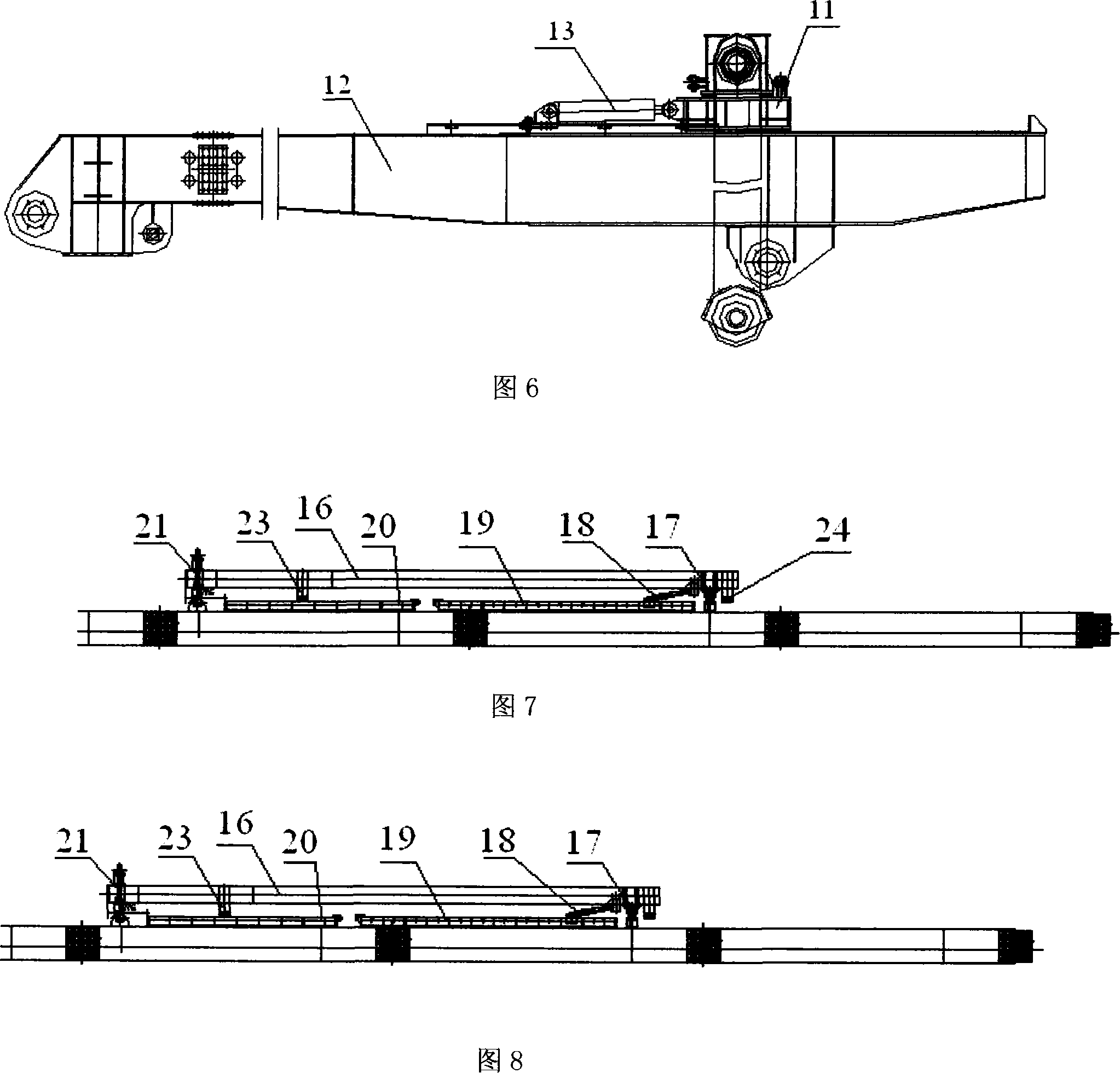

[0016] As shown in Figures 1 and 3, the present invention is composed of a frame 1, a crane, a machine forward mechanism, a suspension point translation mechanism and an anchoring device. 3 is equipped with pulley 4, and pulley 4 is connected with the moving pulley block 5 of crane by steel cable 6, and leveling oil cylinder 7 is housed on the hanger main beam 2, and the piston rod 8 of leveling oil cylinder 7 is obliquely fixed on the pull plate 3. The relative angle between the main beam of the spreader and the moving pulley block 5 is changed by the expansion and contraction of the piston rod 8 of the leveling oil cylinder 7 to achieve the purpose of slope adjustment. As shown in Figure 4, the two ends of the main beam 2 of the spreader are connected with a pole beam 9 through a boom, and the two ends of the pole beam 9 are provided with hinged lifting lugs 10; as shown ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com