Conveyor and intelligent warehousing system

A conveyor and conveying mechanism technology, applied in the direction of conveyors, conveyor objects, transportation and packaging, etc., can solve problems such as high cost, limited applicable scenarios, and certain requirements for conveyor height, and achieve low cost and intelligent level The effect of high height and small equipment footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

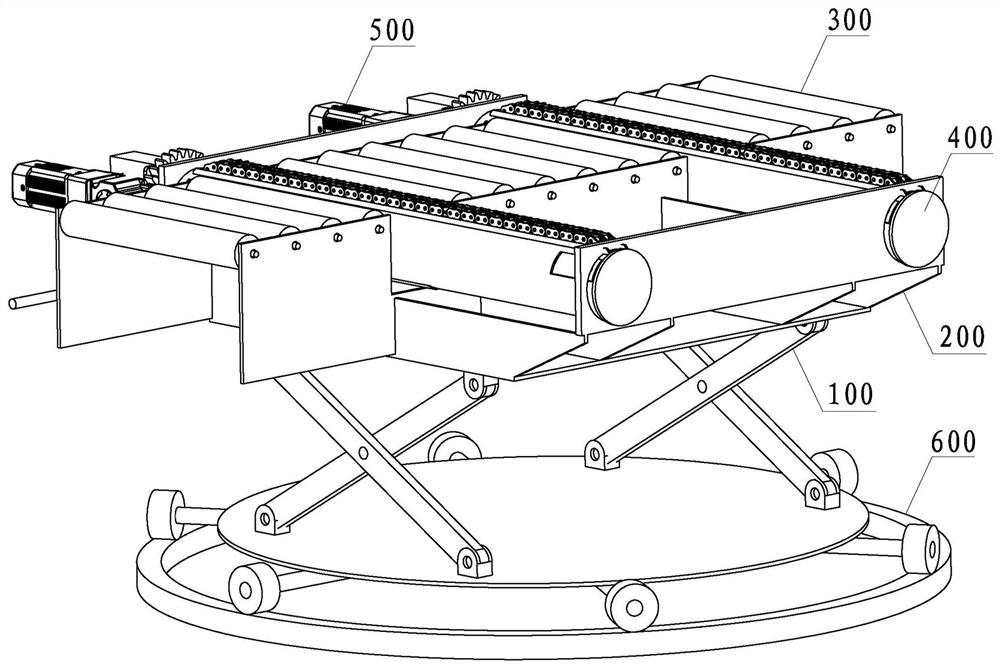

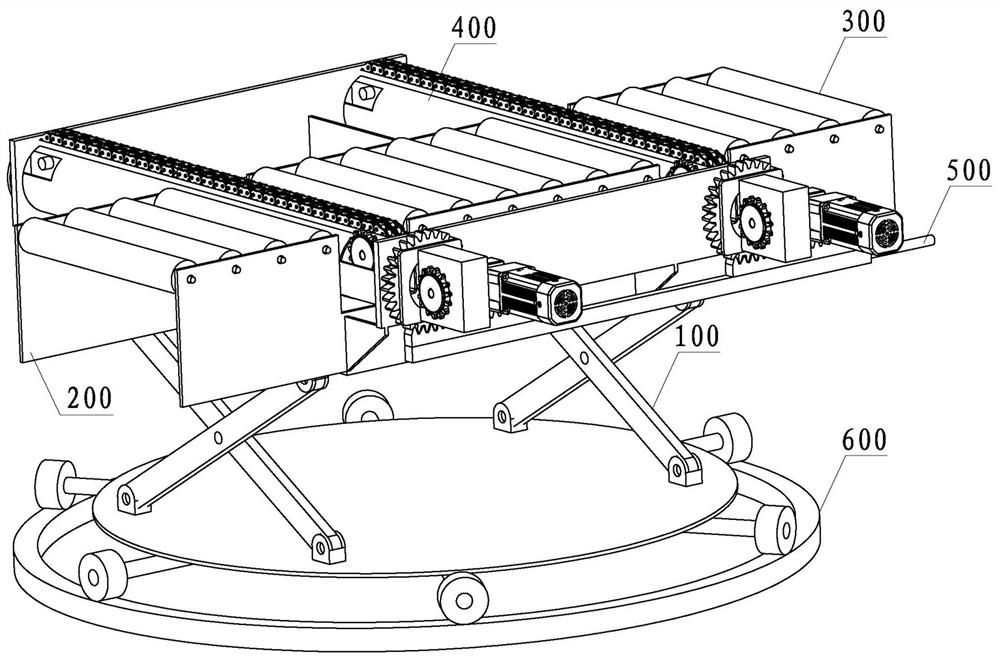

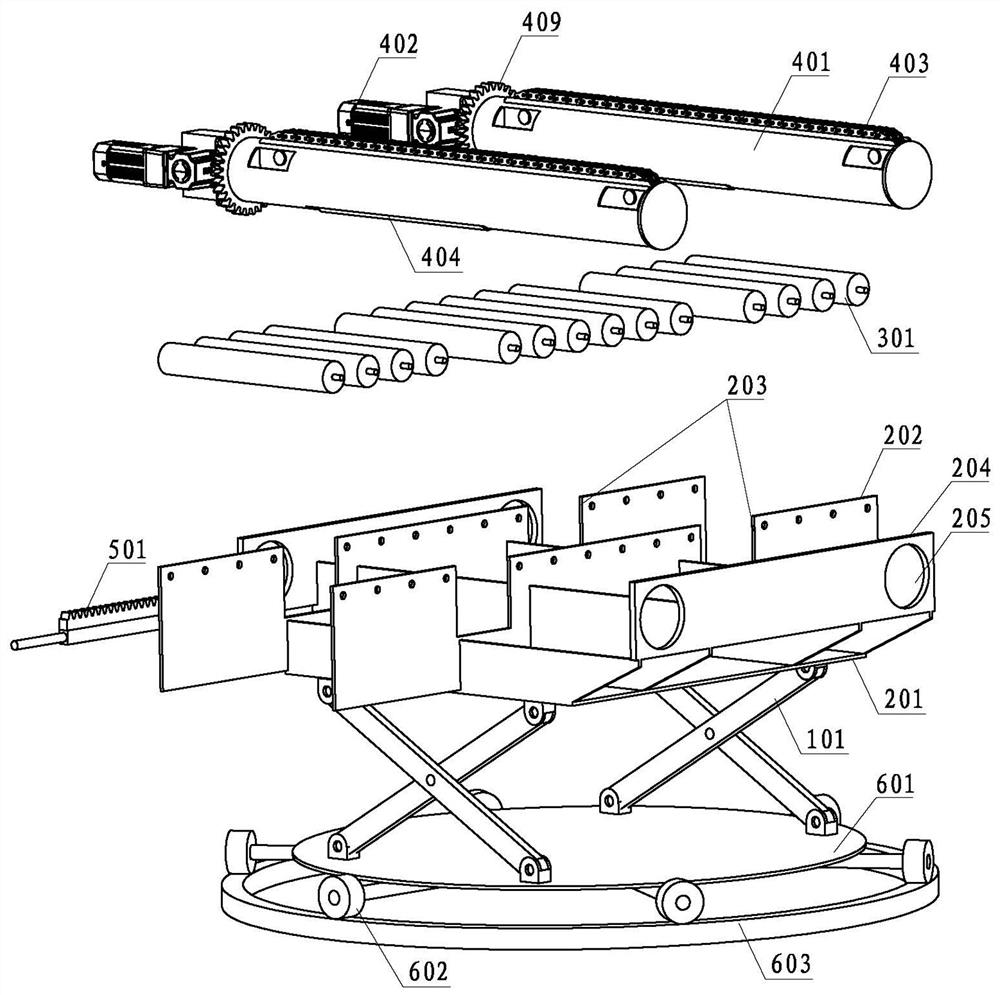

[0030] Such as Figure 1 to Figure 2 As shown, a conveyor includes a lifting mechanism 100 and a reversing conveying mechanism arranged above the lifting mechanism 100 . The lifting mechanism 100 is used to adjust the height of the reversing conveying mechanism, so as to facilitate docking with the truck compartment or other loading and unloading platforms. The reversing conveying mechanism can have the functions of conveying and reversing at the same time, and can transfer goods flexibly.

[0031] The reversing conveying mechanism includes a support frame 200 , a roller conveying unit 300 and a chain-roller assembly unit 400 disposed on the support frame 200 , and a reversing unit 500 that drives the chain-roller assembly unit 400 to turn over. There are at least two chain-roller combination units 400 installed at intervals between the conveying rollers 301 of the roller conveying unit 300 . Specifically, the length direction of the conveying roller 301 is consistent with t...

Embodiment 2

[0045] This embodiment provides a smart storage system, including the conveyor in Embodiment 1, and also includes a ground rail 701 and a vertical support 702 that can move along the ground rail 701. The support 702 is provided with a lifting platform 703, and the lifting platform 703 is provided with a goods conveying mechanism 704 for receiving the cargo box from the conveyor and delivering the cargo box to the shelf 705 . The cargo conveying mechanism 704 may adopt a roller conveying line.

[0046] During specific implementation, the high position and the low position of the lifting platform 703 correspond to the high position and the low position of the shelf 705 respectively, and the lifting platform 703 is provided with a first sensor and a second sensor, and the first sensor is used to sense the height of the roller conveying unit 300 , the second sensor is used to sense the layer height of the shelf 705, and the lifting platform 703 is also provided with a third sensor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com