Method for preventing and controlling structure biological defilement in water environment

A biofouling and structure technology, applied in the field of electrochemistry, can solve the problems of difficult operation stability and safety, expensive DSA electrodes, operating voltage and electrode replacement, operation and maintenance inconvenience, etc., to achieve good antifouling effect, equipment The effect of simple operation and significant environmental protection value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

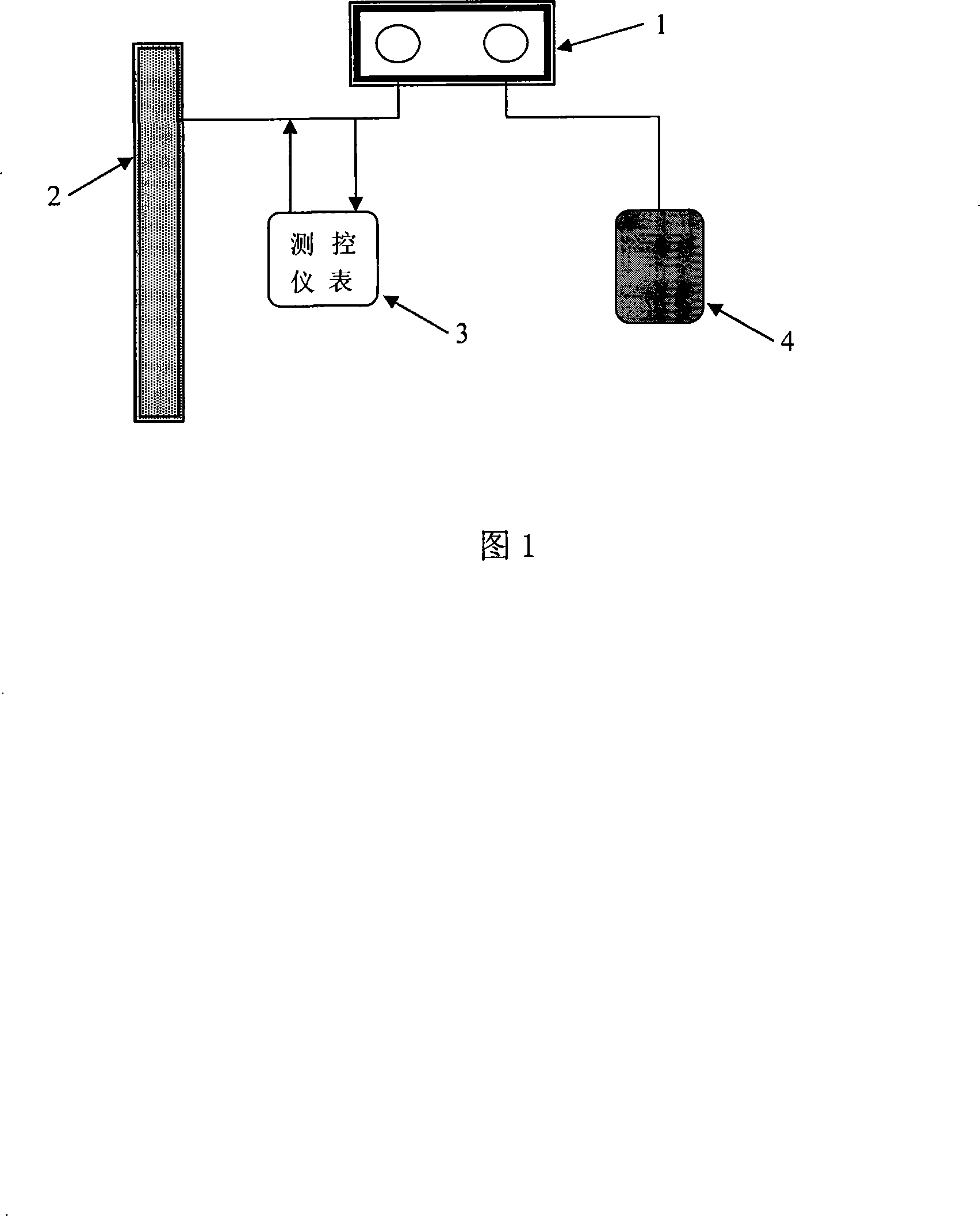

Image

Examples

Embodiment 1

[0016] Embodiment one: laboratory culture

[0017] Establish a 500L seawater culture tank in the laboratory, the total salinity of seawater is 2.87 (g / 100g seawater), the concentration of calcium and magnesium ions is 0.63 (g / 100g seawater), the built-in biochemical filter is used to maintain water quality and dissolved oxygen, and the temperature relay and heating are used. The stick control culture temperature was 24°C, and the most typical fouling organism in the coast of China, Chthamalus challenger, was used as the culture object for the experiment. Using a DC stabilized power supply, the surface potential is negatively shifted by 0.90V based on the self-corrosion potential of the metal surface. At this time, the surface current density is 2.38×10 -6 mA / cm 2 . The cathodic experiment 316L stainless steel sheet mechanically polished with 500# sandpaper was immersed in seawater for protection test, and at the same time, it was put into a non-energized stainless steel shee...

Embodiment 2

[0018] Example 2: Sea water pendant experiment

[0019] At the inlet of a cooling seawater pipeline in a power plant, 6 sets of 316L stainless steel sheets and 6 titanium sheets were hung, and metal cathode test sheets were used for experiments, and their potentials were negatively shifted by 0.6V, 0.8V, 1.0V, 1.2V, 1.4V, and 1.6 respectively. V, put in hanging pieces of the same material size at the same time for comparison. After 64 days of hanging plate experiments, the surface of two hanging plates in the comparison hanging plate was almost covered with barnacles and mussels, and a small amount of limpets were attached, and there was no macroscopic biological adhesion on the surface of each hanging plate with cathodic current.

Embodiment 3

[0020] Example 3: Practical Application in the Factory - Trash Rack

[0021] Conduct cathode current on the second and third trash racks with a diameter of 5m in the No. 2 seawater cooling pipeline of a certain power plant, so that the potential is constant at a negative shift of 0.82V. Except for a small amount of adhesion, the overall protective effect is good. Taking half a year as the comparison period, the antifouling effect is better than the original electrolytic antifouling system whose operating cost is about 40 times that of this technology. At the same time, as a comparison to the same ruler grid that did not use any anti-fouling measures for the No. 1 pipeline due to equipment damage, barnacles and mussels had grown over the entire component, basically blocking the seawater pipeline.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap