Lighting tube heating mechanism for lighting tube bender for ring fluorescent lamp

A technology of heating device and fluorescent lamp, which is applied in glass forming, glass remolding, and manufacturing of ships or lead-in wires, etc., can solve the problems of easy deformation of the copper tube of the burner, insufficiency of the copper tube of the burner, uneven heating of the glass tube, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

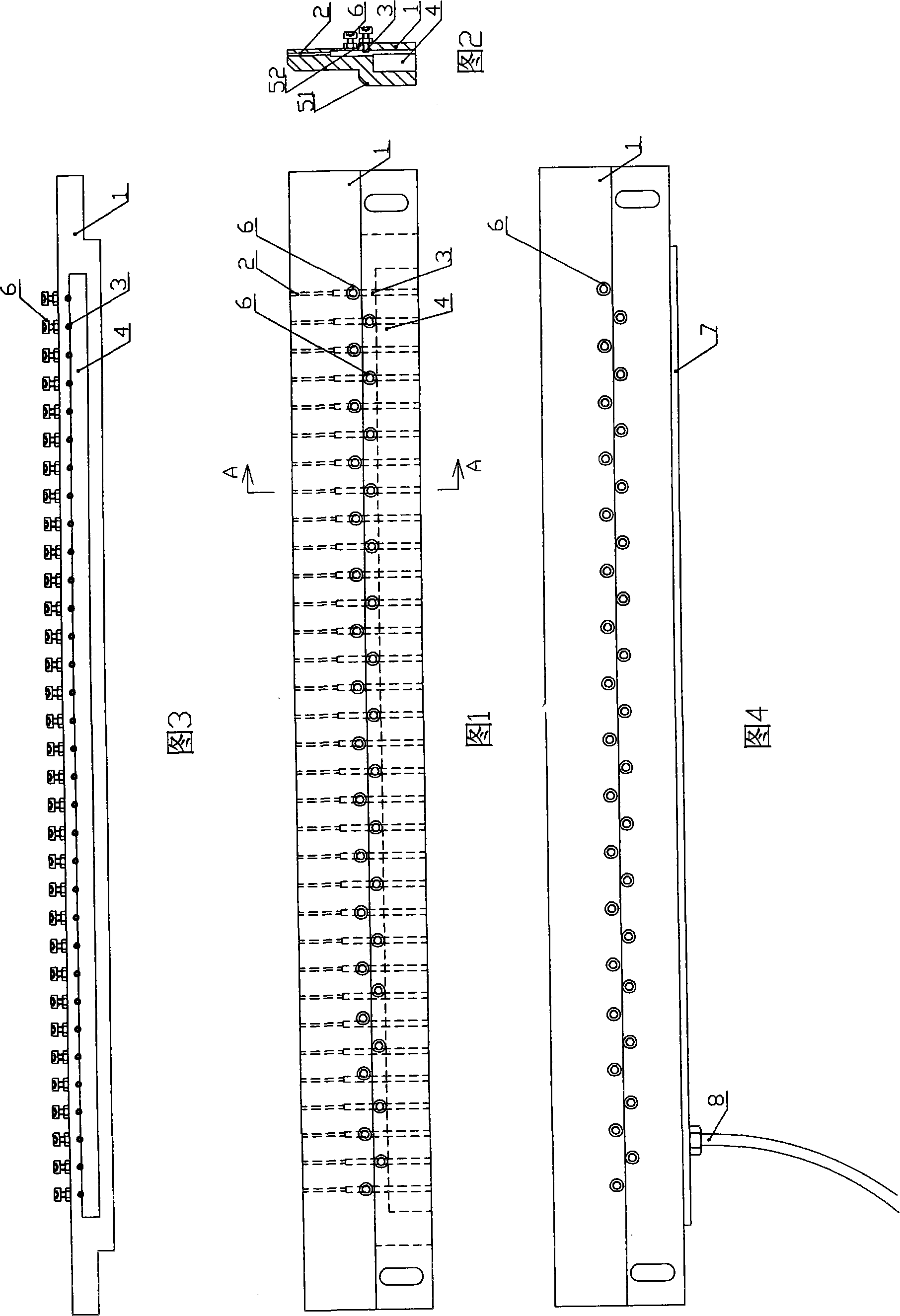

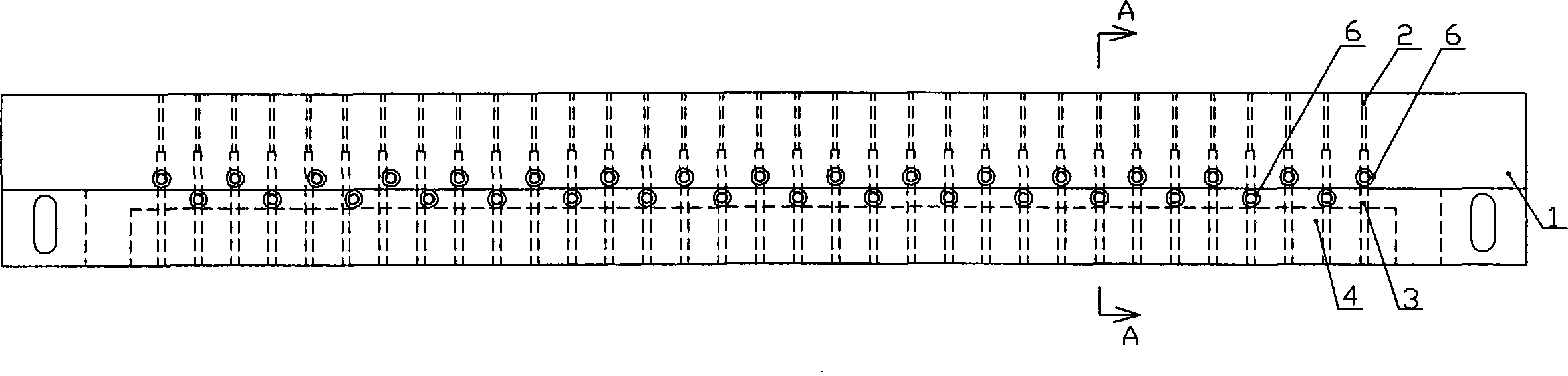

[0008] Refer to attached picture. The present invention comprises a main body 1, on which a fire head hole is opened in a row, and the fire head hole is a stepped hole with a small inner diameter at the front part 2 and a large inner diameter at the rear part 3, and an adjustment is provided at the hole section 3 with a large inner diameter. Flame-sized bolts6.

[0009] The above-mentioned "opening in rows on the main body" can be set up in a single row or in double rows or in multiple rows. Can be staggered.

[0010] In order to facilitate the adjustment and make the burner holes reasonably close, so as to facilitate the uniform heating of the glass tube, as shown in the figure, in this embodiment, the front and back positions of the adjacent bolts on the main body are staggered.

[0011] The main body is provided with an air storage groove 4 behind the burner hole, and the notch of the air storage groove is provided with a sealing plate 7 with connecting holes; Stepped, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com