Test system and method for magnetic property of after-current actuating protector magnetic core

A technology of residual current and testing system, which is applied in the direction of magnetic performance measurement, instrumentation, measuring electricity, etc., can solve problems such as difficult to meet the requirements of fast and accurate magnetic core testing, and achieve the effect of correcting test errors and ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

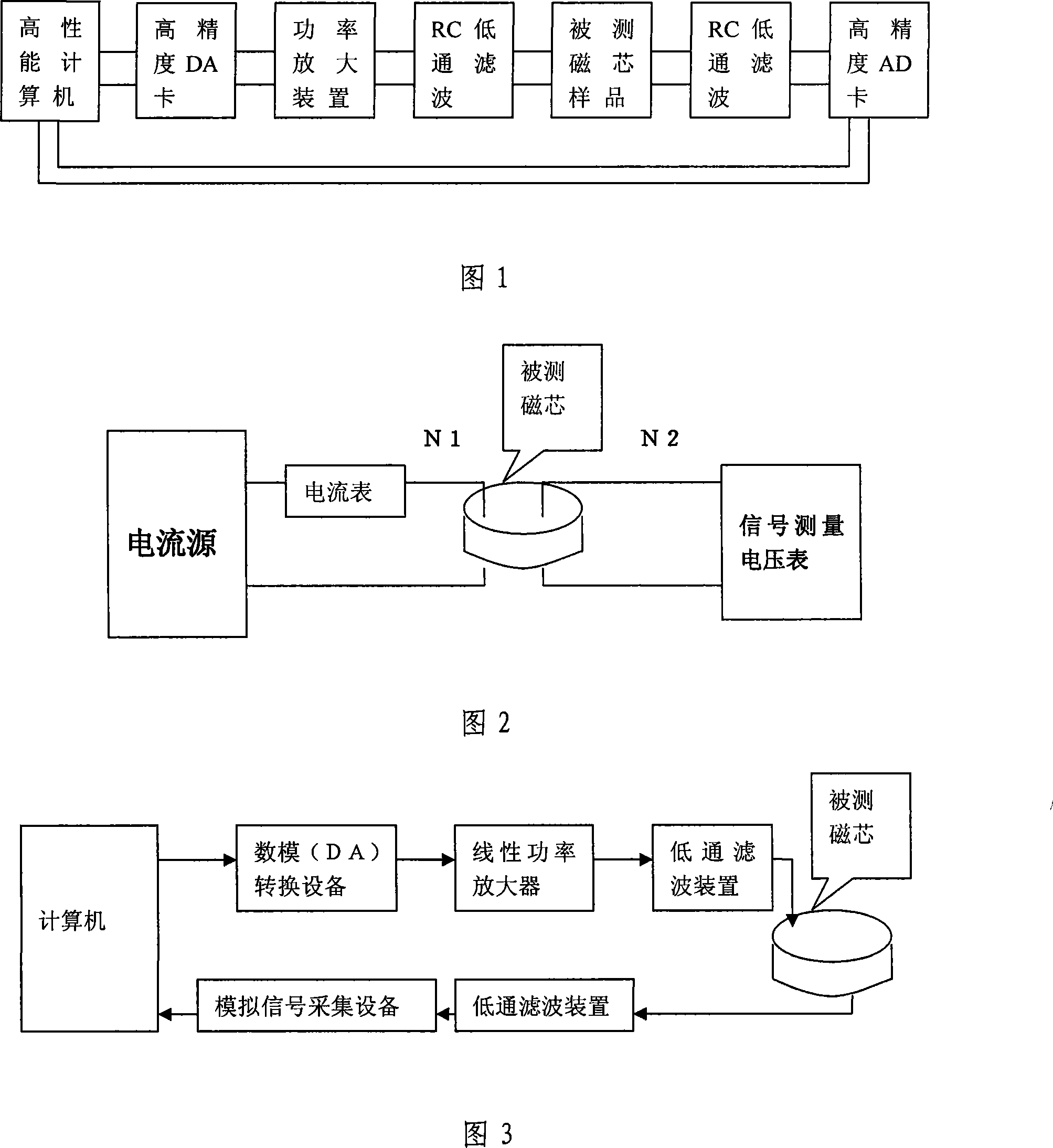

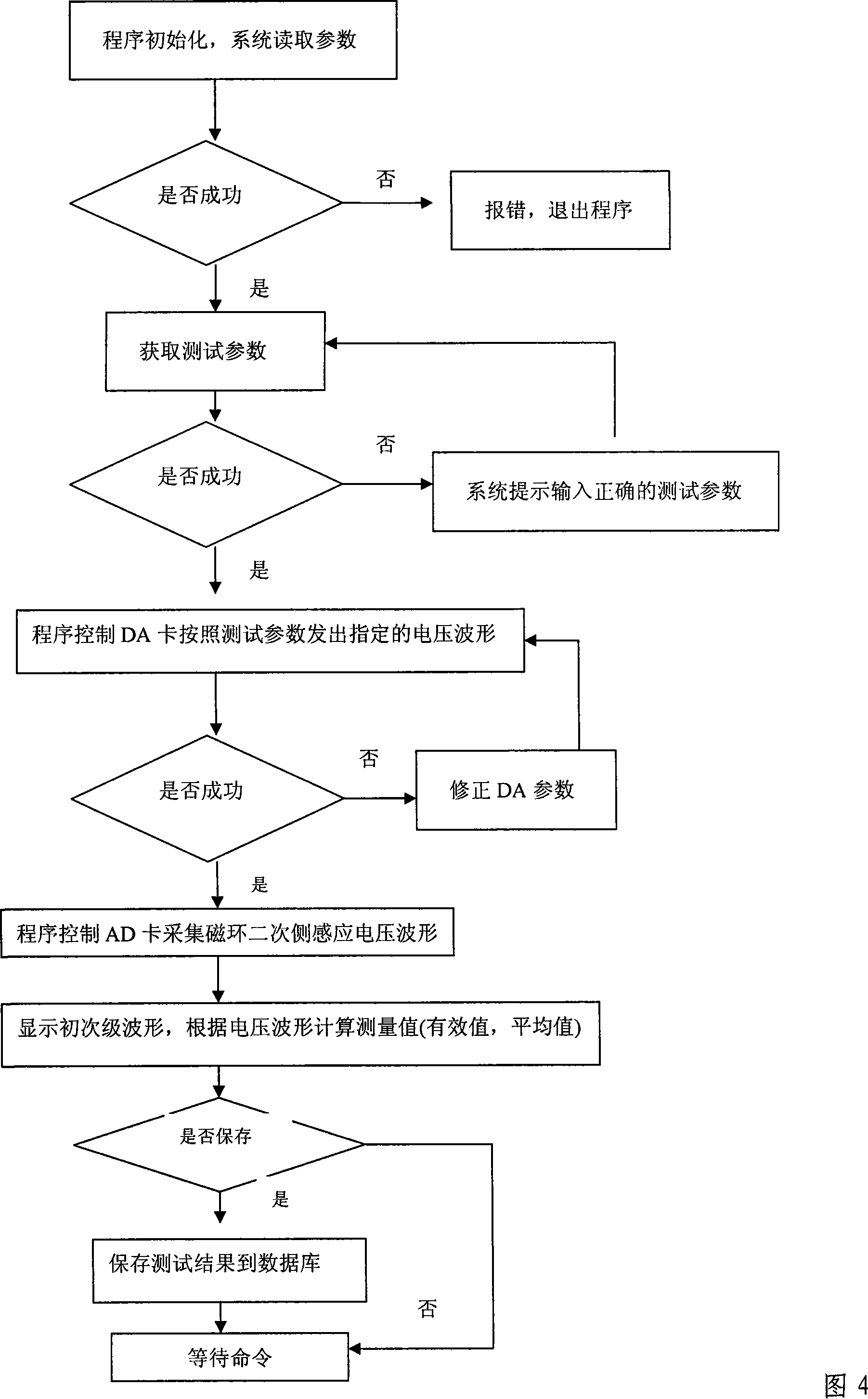

Method used

Image

Examples

Embodiment 1

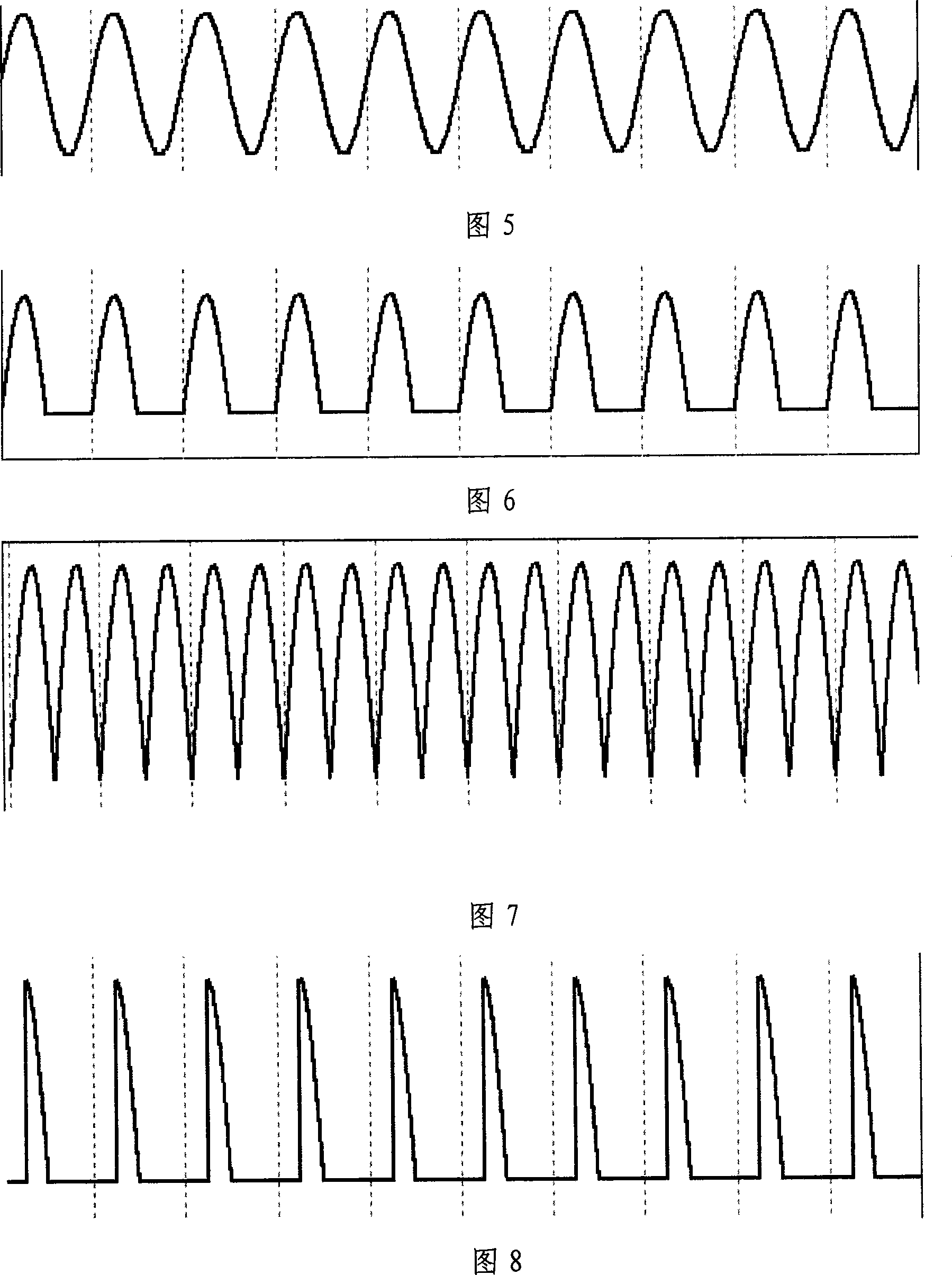

[0051]Take a 23-14-18mm magnetic core, the number of turns of the primary coil: the number of turns of the secondary coil = 1:1, apply a 50Hz positive half-wave current to the primary coil, and the effective value of the current is 40mA, and the induced voltage on the secondary coil The average waveform is fed back to the computer, the average induced voltage is 4.026mV, and the test time is 0.9s.

Embodiment 2

[0053] Take a 23-14-18mm magnetic core, the number of turns of the primary coil: the number of turns of the secondary coil = 1:1, apply a 50Hz positive full-wave current to the primary coil, and the effective value of the current is 40mA, and the induced voltage on the secondary coil The average waveform is fed back to the computer, the average induced voltage is 4.107mV, and the test takes 1.1s.

Embodiment 3

[0055] Take a 23-14-18mm magnetic core, the number of turns of the primary coil: the number of turns of the secondary coil = 1:1, apply a 50Hz standard sine wave current to the primary coil, the effective value of the current is 40mA, and average the induced voltage on the secondary coil The value waveform is fed back to the computer, the average value of the induced voltage is 5.355mV, and the test time is 1.0s.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com