Power semiconductor device

A technology of power semiconductors and semiconductors, which is applied in the direction of semiconductor devices, circuits, electrical components, etc., can solve the problems of large amount of metal film etching, low etching precision, and easy scattering, etc., and achieve width reduction, scattering minimization, excellent long-term Effect of Forward Blocking Voltage Capability on Reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] Hereinafter, embodiments of the present invention will be described in detail with reference to the accompanying drawings. The present invention is not limited only to the embodiments described hereinafter.

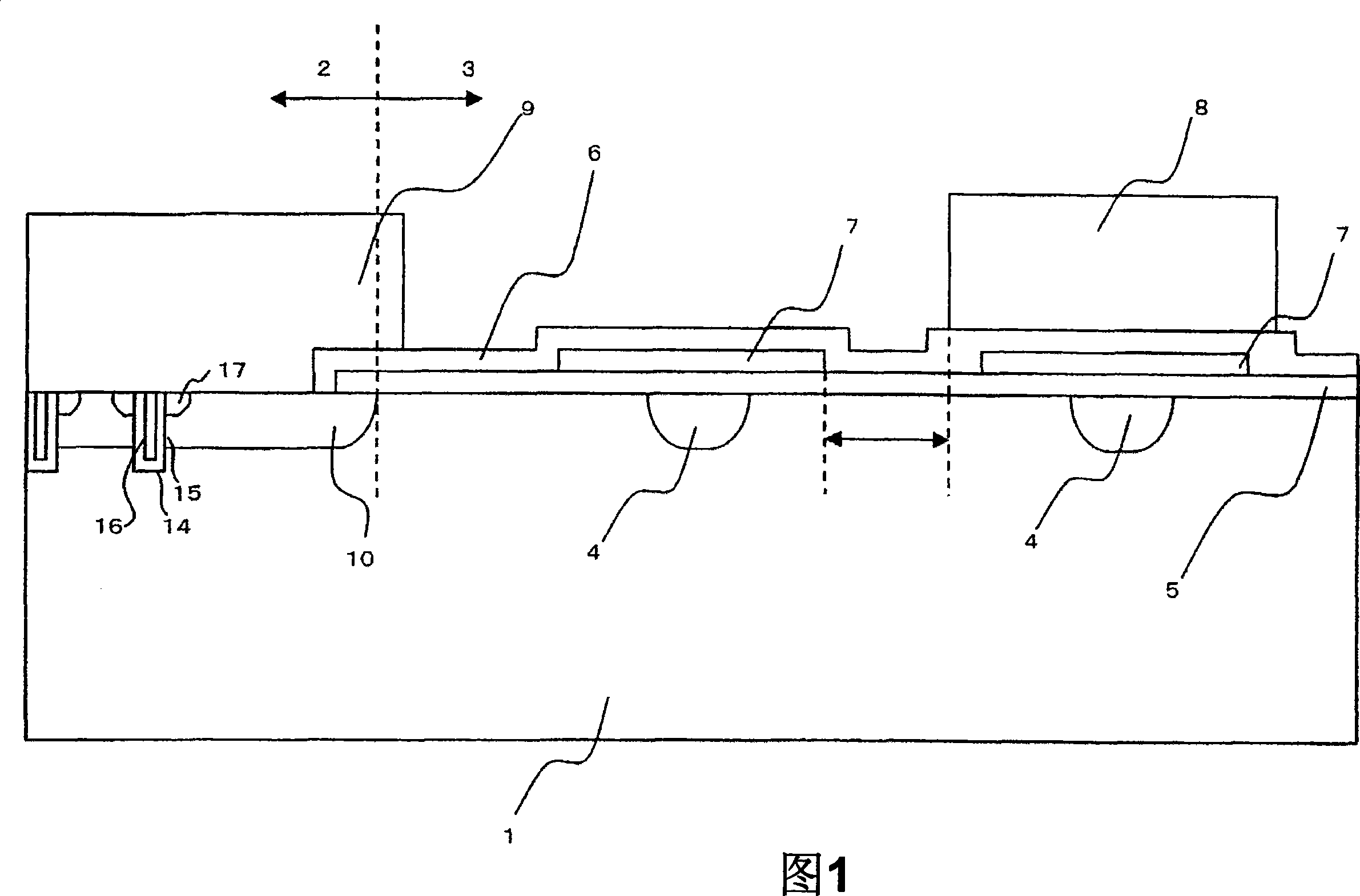

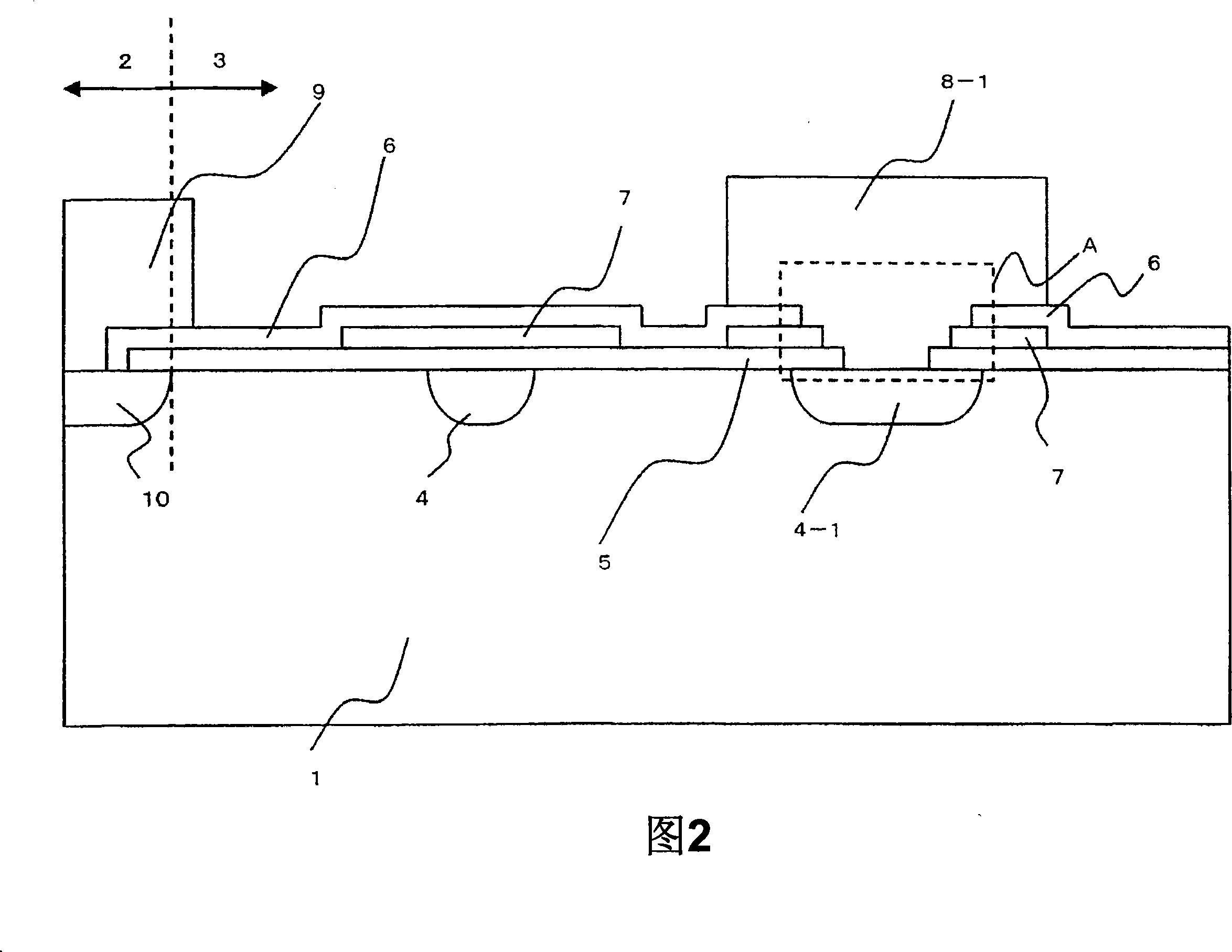

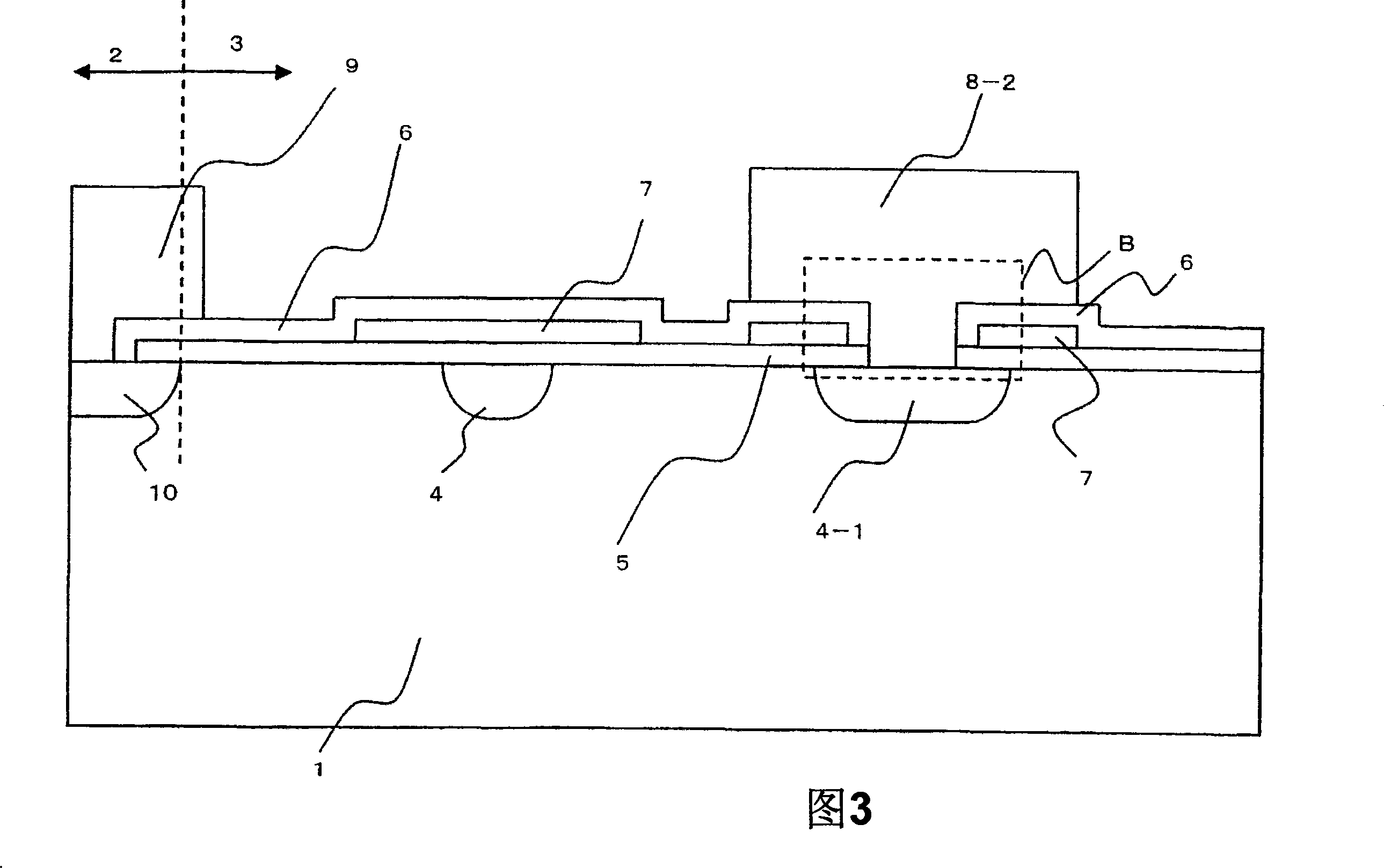

[0050] 1 to 4 are main part cross-sectional views of different edge termination structures of the power semiconductor device of the present invention. 5-1 to 5-3 are cross-sectional views of different edge termination structures in corner portions of the power semiconductor device of the present invention. 6 is an enlarged cross-sectional view of an edge termination structure in a corner portion of the power semiconductor device of the present invention. 7-1 to 7-4 are cross-sectional views taken along the line XX' of the edge termination structure of FIG. 5-1(b), which are used to illustrate the method of manufacturing the power semiconductor device of the present invention. Fig. 8 is a cross-sectional view taken along line Y-Y' of Fig. 5-1(b), showing the non-c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com