Non-contact electricity feeding system and running vehicle using this

A power supply system, non-contact technology, applied in electromagnetic wave systems, electric vehicles, devices along the driving track, etc., can solve the problems affecting laser and semiconductor inspection, affecting electronic equipment, etc., to reduce the impact and weaken the leakage magnetic field effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

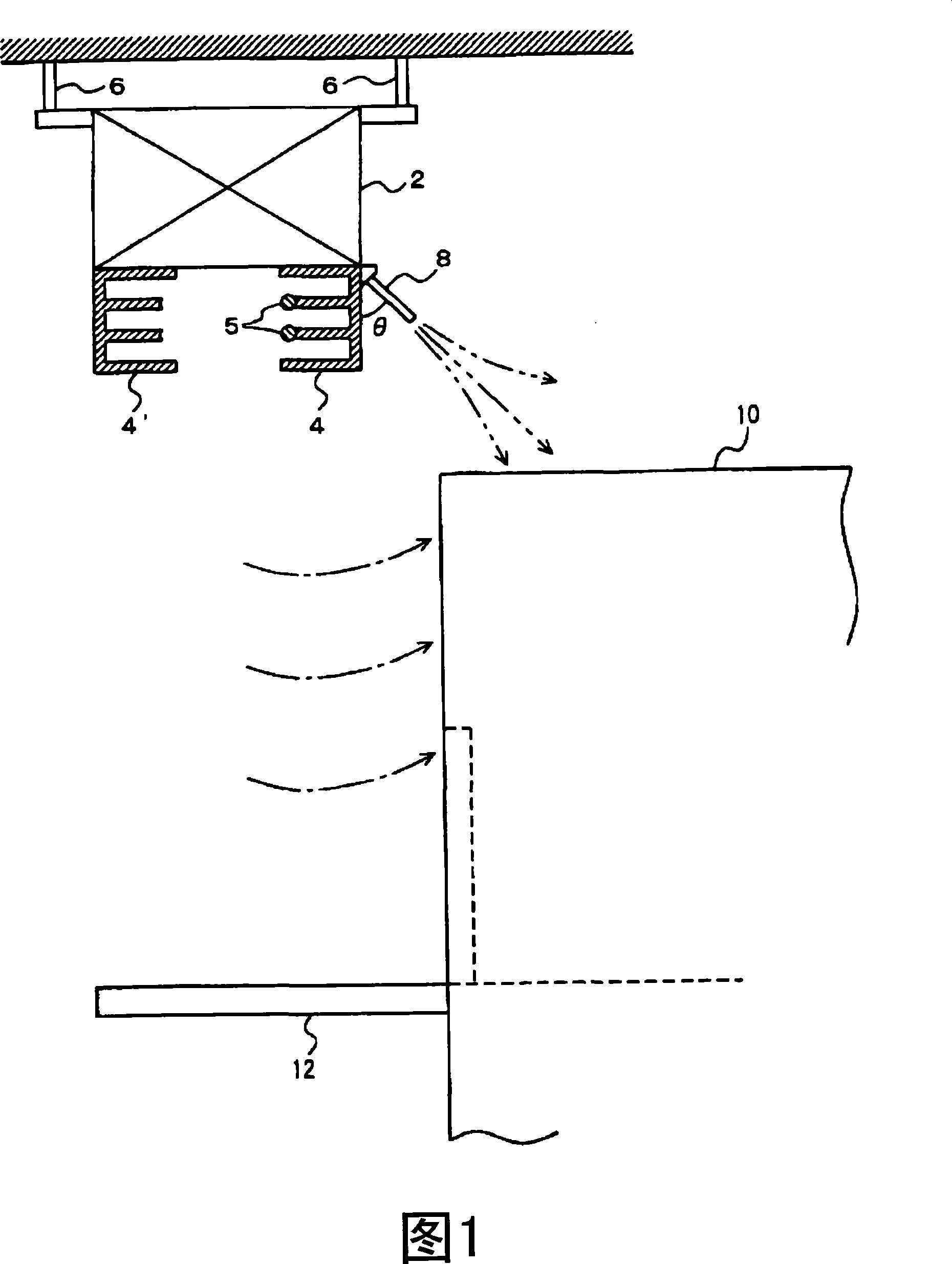

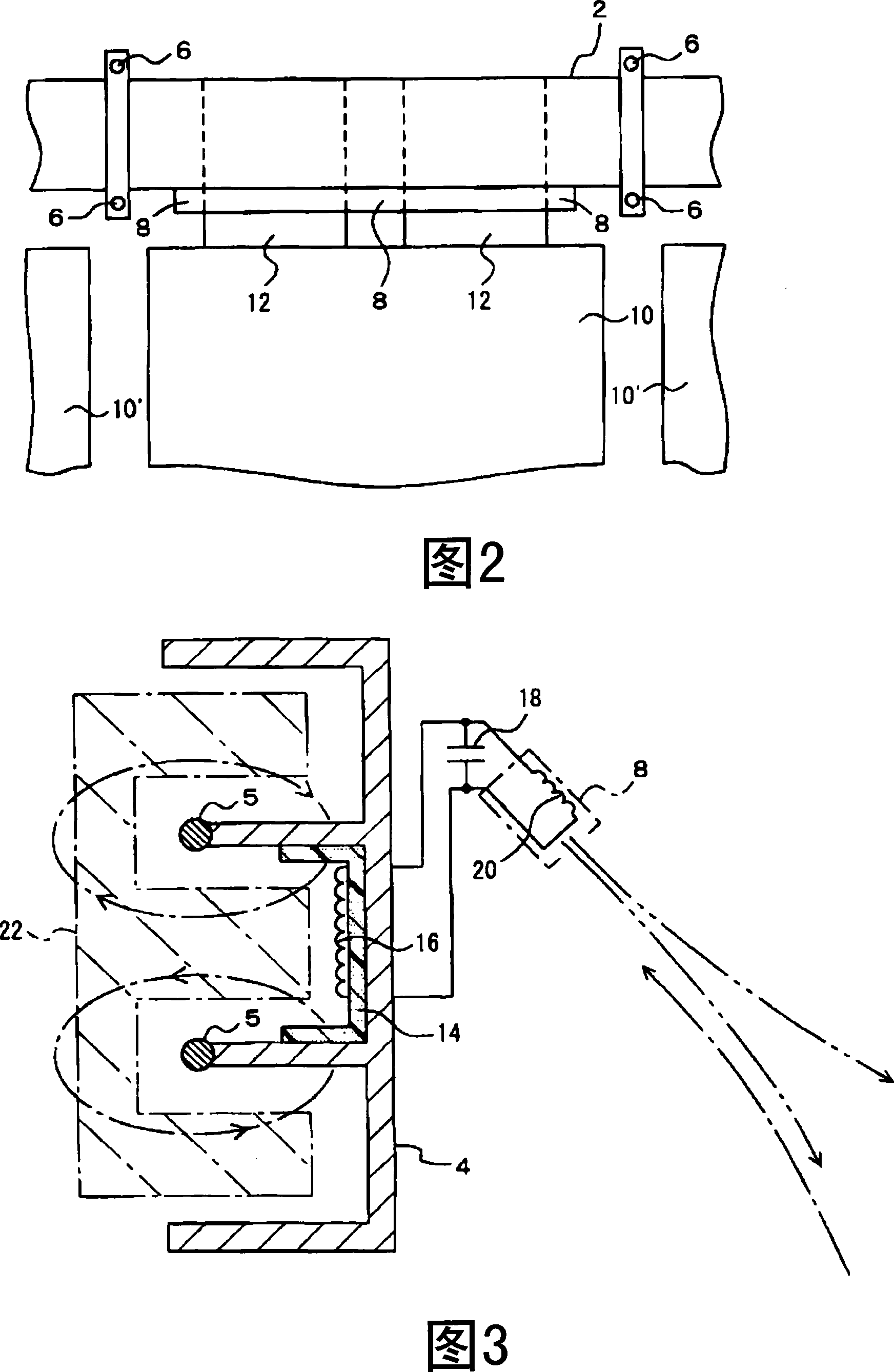

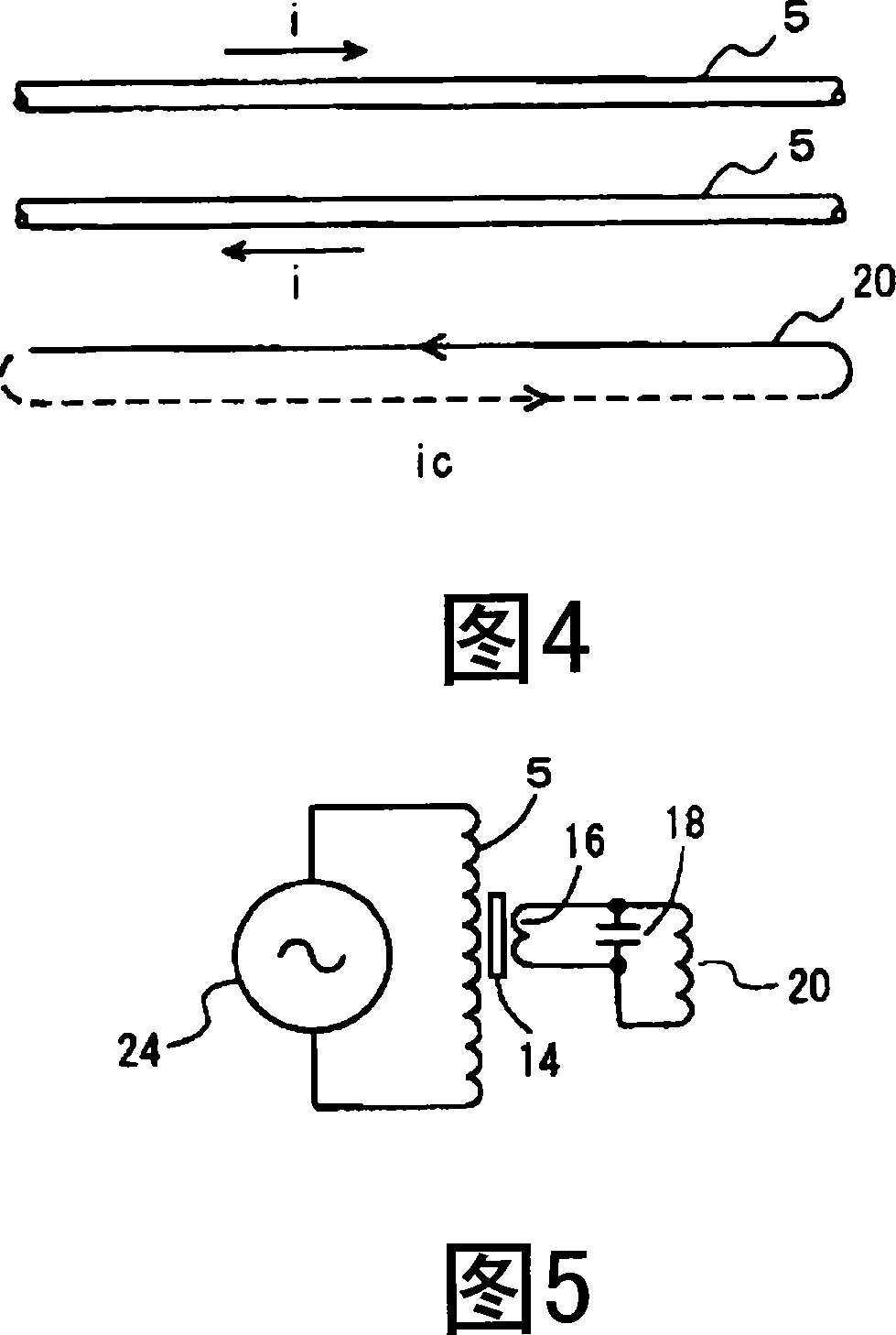

[0019] 1 to 5 show examples. In each figure, 2 is a running track, and a pair of left and right power supply rails 4, 4' are arranged on the lower part thereof, and a pair of power supply lines 5, 5 are arranged on the power supply rail 4, for example. In addition, the power supply rail 4 ′ may use a turning section or the like, or physically make the power supply rails 4 and 4 ′ a part of the running rail 2 . From an AC power source not shown in the figure, an AC of about 10 KHz flows through the power supply line 5, and the magnetic field generated by the power receiving coil of the overhead traveling vehicle not shown in the figure receives power to perform non-contact power supply. The electromagnet core is, for example, a member in which a coil is wound around a magnetic core.

[0020] 6 is a pillar, and the traveling track 2 and the power supply rails 4, 4' are arranged in the clean room, and the bridge type traveling vehicle transports such as semiconductor boxes or re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com