Heater cable combined with lead-wire cable

A lead cable and heater technology, applied in the direction of ohmic resistance heating parts, heating element shape, etc., to achieve the effect of weakening the leakage magnetic field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

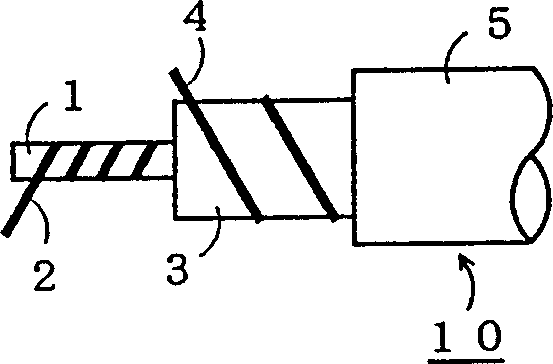

[0052] figure 1 It is a schematic diagram showing the structure of a heater cable used in the circuit pattern of the present invention.

[0053] like figure 1 As shown, the structure of the heater cable 10 includes a core wire 1, a heating element wire 2 wound in a spiral shape on the outer surface of the core wire 1 at a given distance interval, and a heating element wire 2 arranged on the heating element A fuse layer 3 on the electric wire 2, a signal wire 4 wound in a spiral shape on the outer surface of the fuse layer 3, and a protective coating 5 provided on the signal wire 4.

[0054] The core wire 1 can be polyester fabric. The heating element wire 2 can be a flat square copper wire, a flat square copper alloy wire, a round copper wire or a round copper alloy wire. The fuse layer 3 can be made of nylon or polyester. The signal wire 4 can be a flat square copper wire, a flat square copper alloy wire, a round copper wire or a round copper alloy wire. This protectiv...

no. 2 example

[0072] Now, in the circuit pattern of the present invention, an embodiment in which the fuse layer is made of copolymer polyester resin will be described. Note that the term "parts" in the following examples represents parts by weight.

[0073] Production of Copolymer Polyester Resin (A) for Experiment 1 Fused Layer

[0074]856 parts of acid groups of dimethyl terephthalate and 897 parts of 1,4-butanediol of diols, together with 0.37 parts of tetra-n-butyl titanate used as catalyst, were added with a Esterification was carried out at a temperature of 160°C to 210°C for 4 hours in a vessel with a stirrer, a thermometer and a distillation condenser. Then, 216 parts of ε-caprolactone of glycols and 1.08 parts of Irganox (a product of Ciba-Geigy Company) used as a stabilizer were added, and mixed at 220° C. for 30 minutes to 1 hour to stimulate further Reaction. After the pressure was reduced to 5 mmHg over the duration of 40 minutes while the reaction temperature was increased...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com