Forme location fixtures and computer direct forme maker having the same

A technology for positioning fixtures and plate making machines. It is applied in the directions of plate preparation, printing, and shim devices. It can solve the problems of inaccurate positioning and deviation of the printing plate, and achieve the consistency, avoid skew and accurate positioning. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] Below in conjunction with accompanying drawing, structural principle and working principle of the present invention are specifically described:

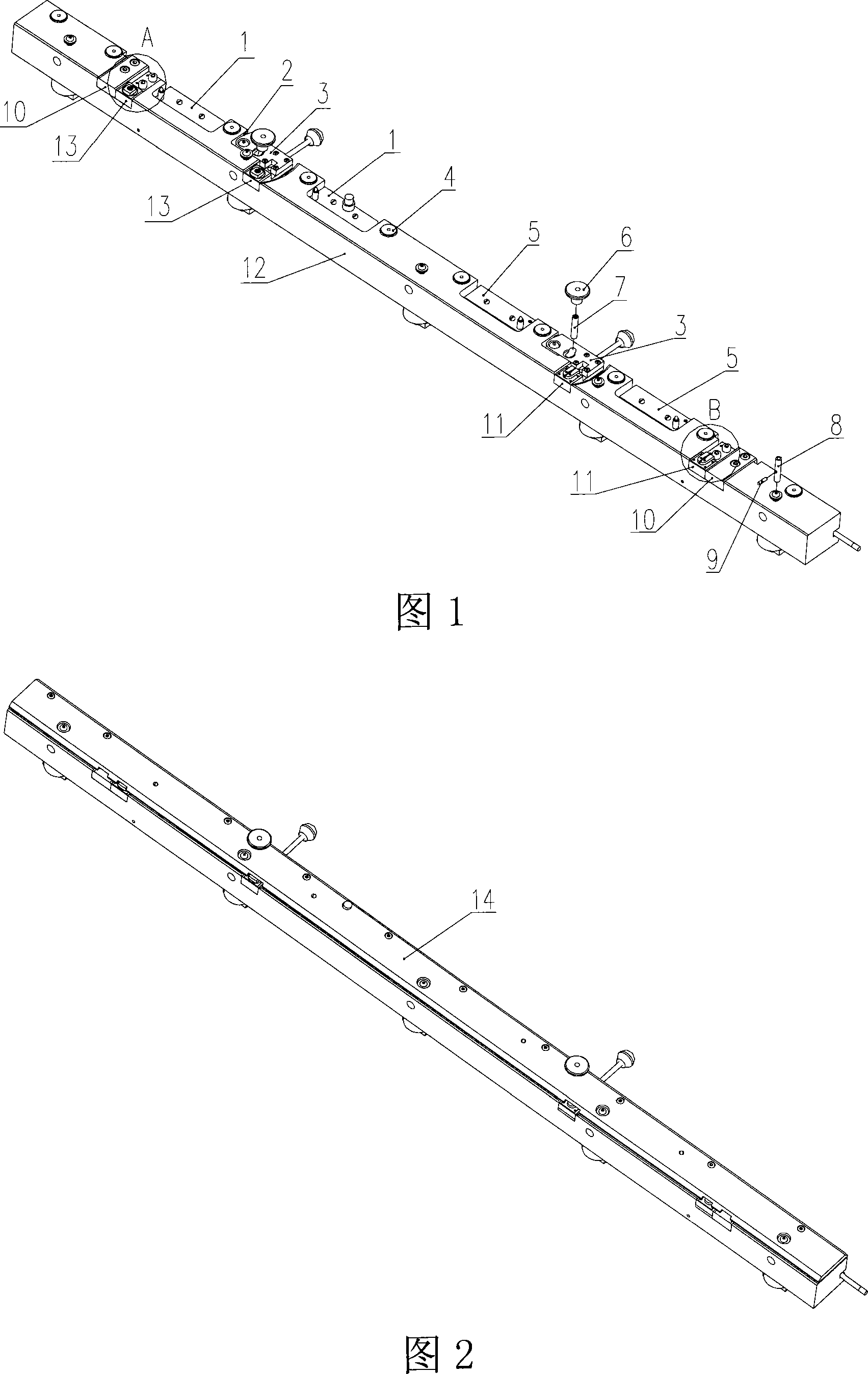

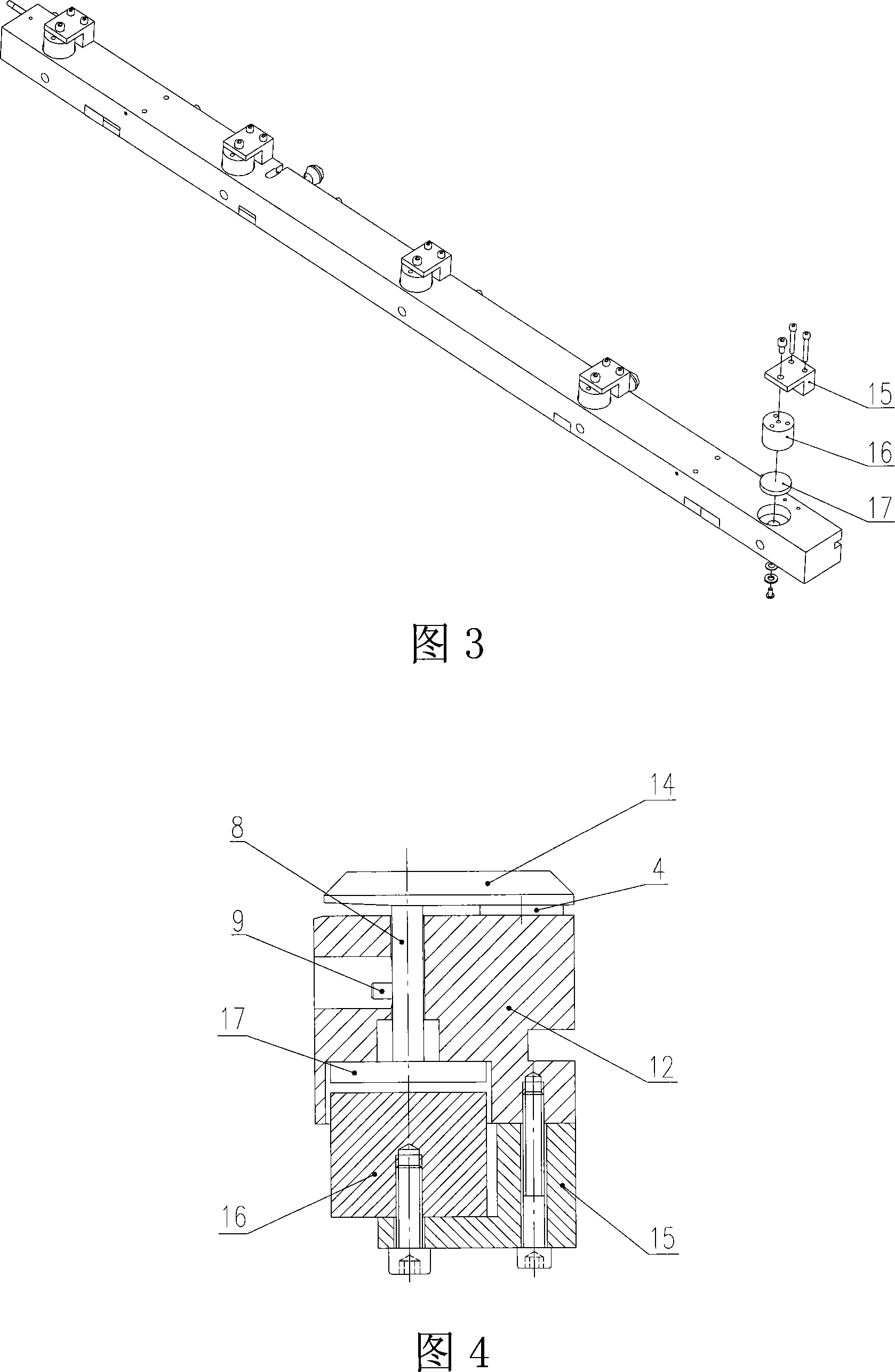

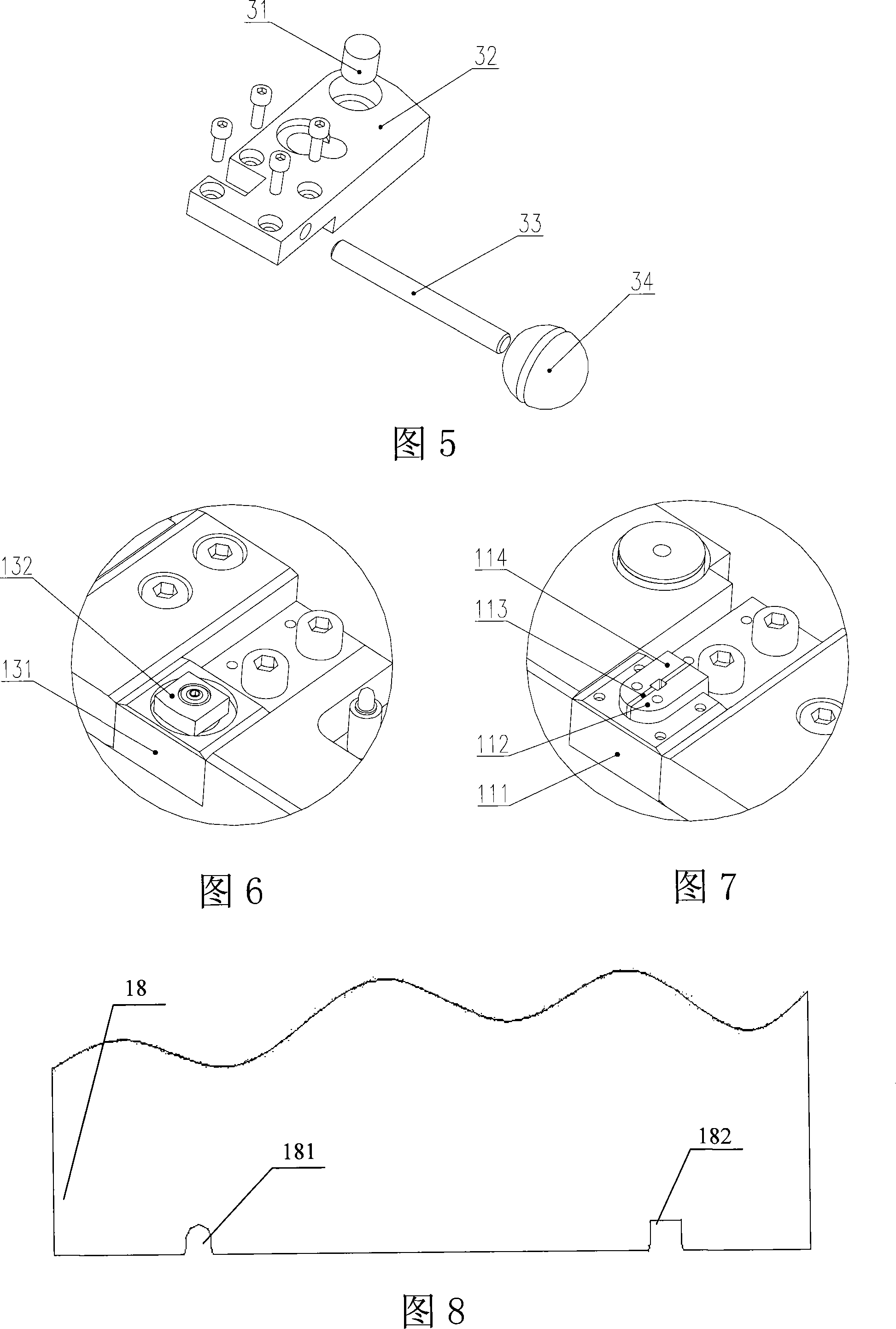

[0057] Please refer to Figure 1 the installation diagram of the printing plate positioning fixture parts; Figure 2 the top assembly drawing of the printing plate positioning fixture; Figure 3 the bottom installation diagram of the printing plate positioning fixture.

[0058] In the specific embodiment shown in the figure, the present invention comprises: substrate 12, U-shaped locating pin device 11, square locating pin device 13, circuit board 1, circuit board 5, top plate 14 and by electromagnet fixing seat 15, electromagnet 16. The clamping device formed by the tray 17 and the pull rod 8 .

[0059]Two sets of locating pin devices consisting of a left U-shaped locating pin device 11 and a right square locating pin device 13 are arranged on the substrate 12, wherein the group adjacent to the edge is a fixed locating pin devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com